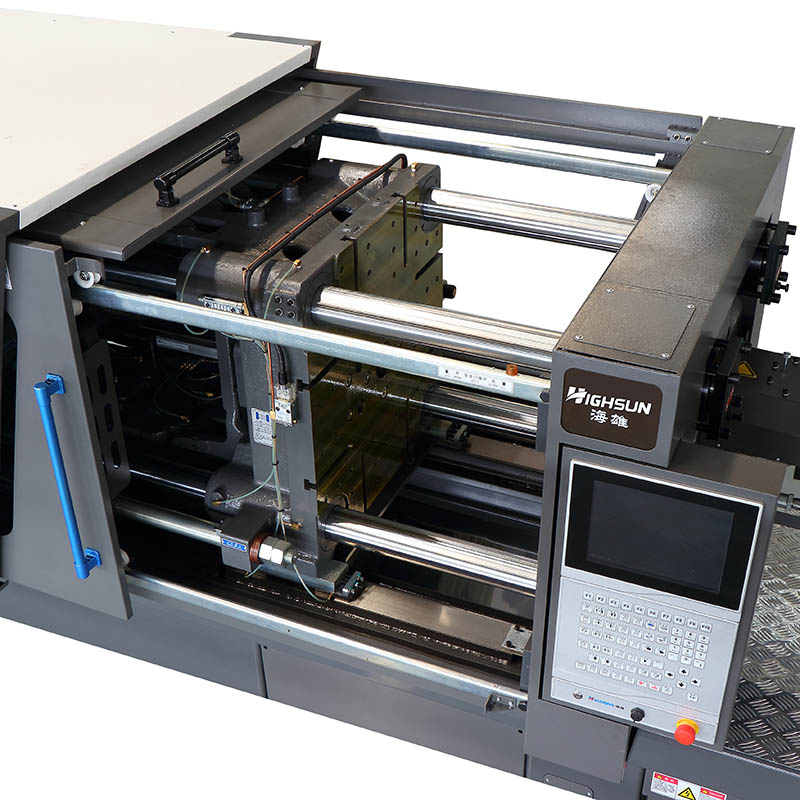

SP300: SP smart power injection molding machine

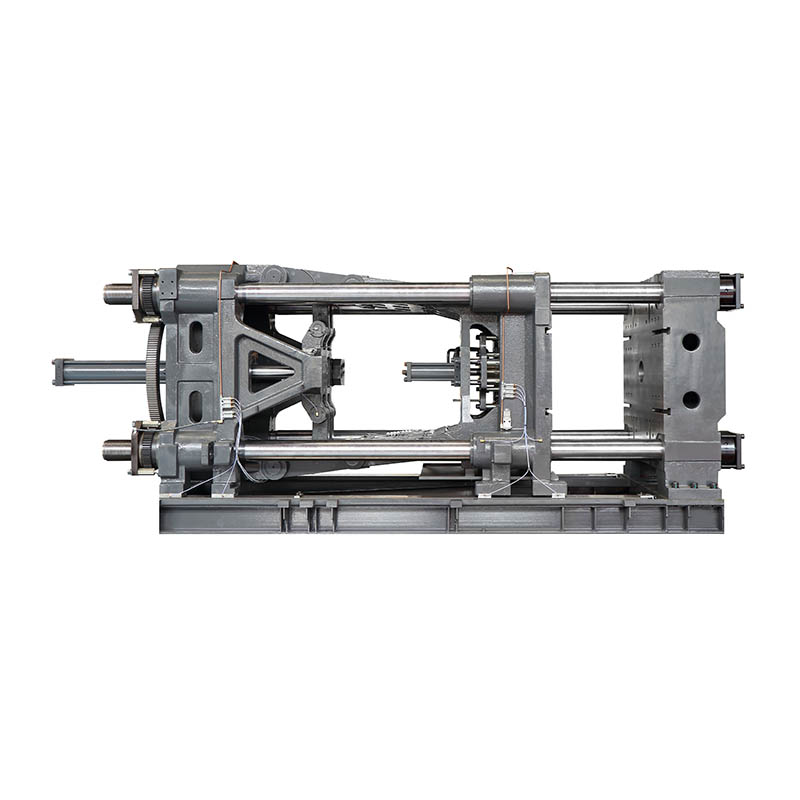

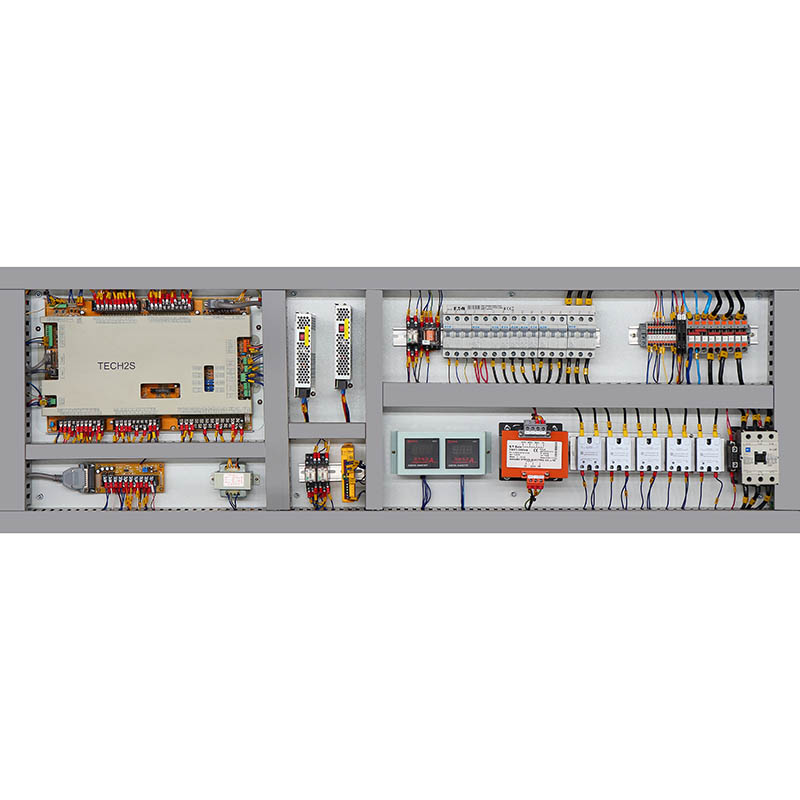

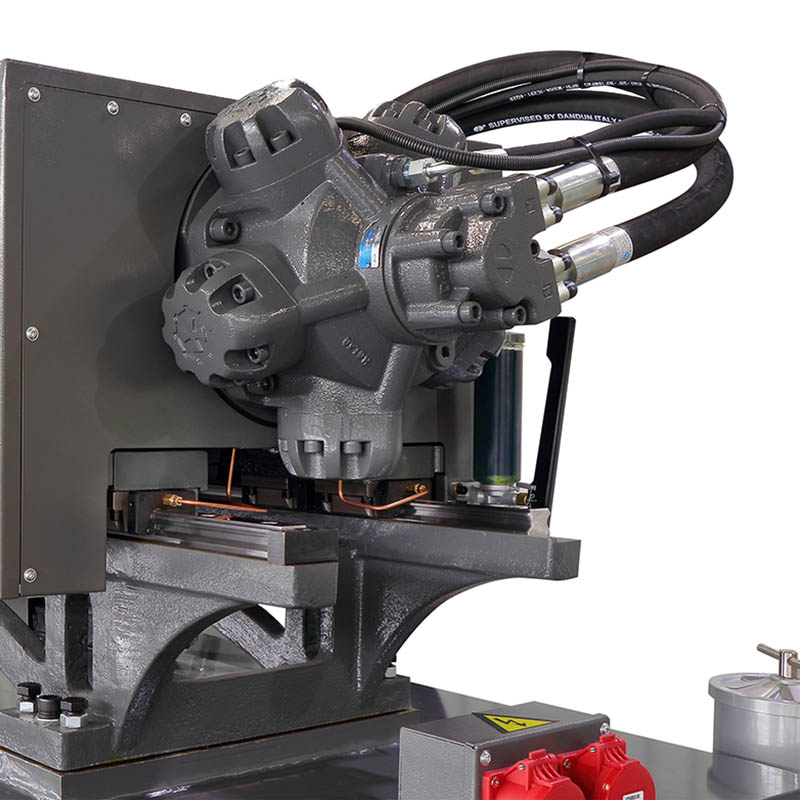

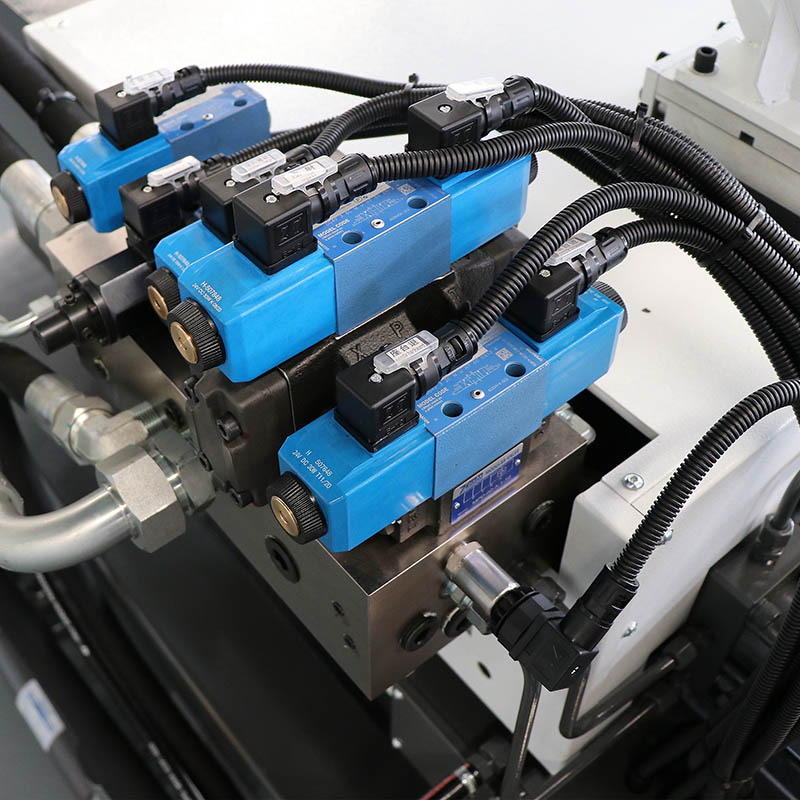

The SP300 injection molding machine is equipped with a new side-mounted mechanical safety structure, which adds reliable safety protection to the operation of the equipment and reduces the risk of accidents. The inclined wedge type sliding foot structure of the moving platen further enhances the stability of the equipment. Its precision control system features stable and reliable operation, high repeatability accuracy, and strong anti-interference ability. This system has an energy consumption monitoring function. Enterprises can, based on different production tasks, rationally adjust the equipment parameters through the system's data analysis to achieve precise control of energy consumption.

ENG

ENG  English

English русский

русский Español

Español Português

Português عربى

عربى

+86-188 6861 6288

+86-188 6861 6288 haixiong@highsun-machinery.com

haixiong@highsun-machinery.com No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China

No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China