|

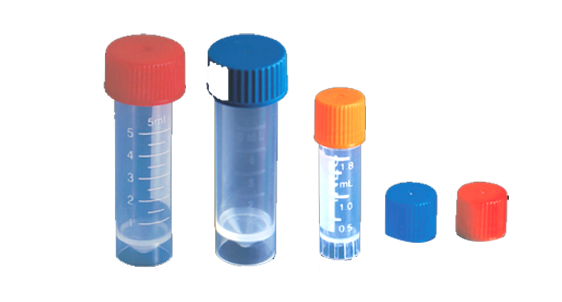

Test tube |

SP300 |

|

|

Cultrure dish |

SP250 |

|

|

Biochemical anaylazer |

SP200 |

|

|

Centrifugal tube |

SP160 |

|

|

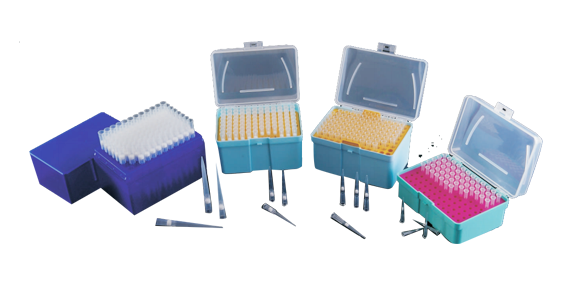

Pipettor |

SP130 |

|

Modern healthcare would be impossible without the many plastic-based medical products we take for granted. With the advancements in the healthcare industry, plastic has proved to be one of the few versatile materials that has been able to adapt along with the dynamic nature of the industry. Disposable plastic syringes, blood bags, new heart valves, and other medical devices are some of the many ways plastics have been used. Thanks to its exceptional barrier properties, it safely guards against contamination. Innovations in plastics are making new procedures possible.

Since plastic can be molded per the requirement of a specific application, it is also being used to develop new medical devices. Plastics are now being used in surgical devices and procedures, and products like modern pacemakers, stents, or joint replacement devices due to its ability to adapt to the tiniest and most intricate molds. Plastics can not only be mass-produced at cost-effective rates, but also allow for a wider range of applications, making it a worthwhile investment.

|

Test tube |

SP300 |

|

|

Cultrure dish |

SP250 |

|

|

Biochemical anaylazer |

SP200 |

|

|

Centrifugal tube |

SP160 |

|

|

Pipettor |

SP130 |

|

|

High accuracy New designed injection cylinder with low oil return resistance, is combined with the structure of the linear guide , which can reduce the friction of the injection part and greatly improve the control precision of the injection unit. |

|

Unique design |

|

|

|

More intelligent : |

|

High efficiency |

|