Choose Based on Product Requirements First — Not Machine Price The right PVC injection molding machine is the one that matches your product size, PVC formulation, and production volume. Clamping force...

READ MORE

|

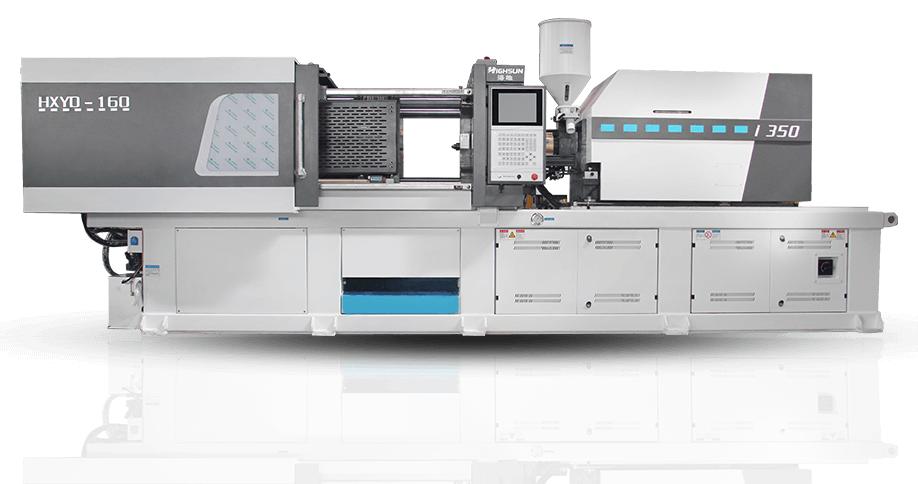

Precision High-Efficiency Injection Molding ● High Dynamic Response ● Energy Saving & Consumption Reduction ● Clean Production Environment |

|

Stable High-Tonnage Mold Clamping (Hydraulic Advantages) ● High Clamping Force ● Superior Eccentric Loading Resistance |

|

Comprehensive Performance Optimization ● Dynamic Speed-Force Synchronization ● Exceptional Cost-Effectiveness |

|

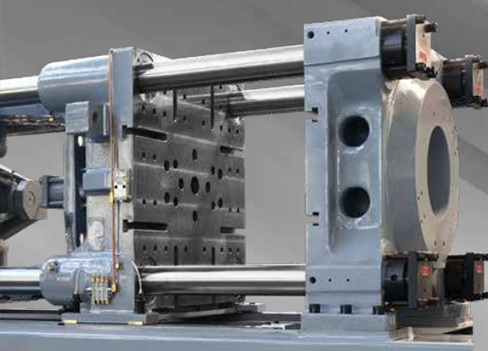

Adopt Digital Communication Non-contact Displacement Sensor for Mold Open/Clamp ● It has features of faster and stable, higher accuracy of position measurement, and higher precision of repetition. |

|

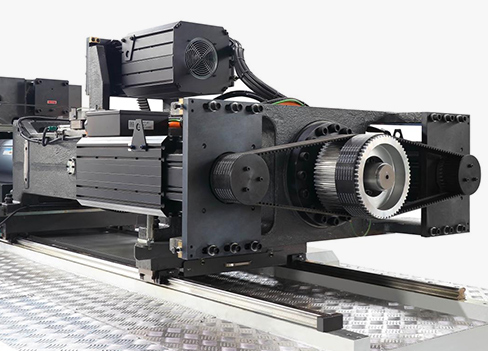

The Pedestal Adopts Linear Guide Rail to Move and the Screw Movement has High Linear Precision Without Deviation. ● The structure of the injection unit is optimized to realize the high-frequency response characteristics of injection and precise control of each action of injection, pressure holding and back pressure. |

Choose Based on Product Requirements First — Not Machine Price The right PVC injection molding machine is the one that matches your product size, PVC formulation, and production volume. Clamping force...

READ MORETroubleshooting Common Issues in PET Preform Injection Molding Machines PET preform injection molding machines are vital for producing high-quality plastic bottles and containers. However, like all m...

READ MOREHow PVC Injection Molding Machines Enhance Production Efficiency PVC injection molding machines can significantly enhance production efficiency by streamlining manufacturing processes, improving prod...

READ MOREThe direct answer is yes: the HXM Servo Injection Molding Machine is designed to deliver high precision, lower energy consumption, and stable production performance, making it ideal for manufacturers ...

READ MOREThe HXYD hybrid injection molding machine represents a significant evolution in manufacturing technology. Combining the strengths of electric and hydraulic systems, it provides an efficient and flexib...

READ MORE1. What is the HXYD Hybrid Injection Molding Machine?

The HXYD hybrid injection molding machine is a high-performance injection molding equipment that combines the advantages of servo electric drive and hydraulic systems. Hybrid technology achieves a balance of speed, precision, and high pressure by using servo motors for key high-speed movements (such as injection and metering), while high-pressure operations (such as holding pressure and mold clamping) are performed by the hydraulic system. The HXYD series injection molding machine is particularly suitable for production scenarios requiring high speed, energy efficiency, repeatability, and stability, and is an optimized solution between traditional all-hydraulic and all-electric machines.

Ningbo Beilun Highsun Machinery Co., Ltd. is a professional China HXYD Hybrid Injection Molding Machine Manufacturers and HXYD Hybrid Injection Molding Machine Factory, We specialise in producing and marketing high-grade precision plastic injection molding machines under the "HIGHSUN" brand. has long been dedicated to delicacy management and zero defect production, and has formed a characteristic series represented by small tonnage of hybrid machine, medium tonnage of toggle machine, and large tonnage of two-platen machine.

2. Main Advantages of the HXYD Hybrid Injection Molding Machine

The core advantages of the HXYD hybrid injection molding machine lie in its high speed, energy efficiency, and precise control. The servo drive system significantly improves injection speed and responsiveness, shortening the molding cycle and making it suitable for thin-walled products and complex structural parts. Compared with traditional hydraulic machines, the hybrid system achieves energy savings of 30%-60%, with lower noise and less temperature rise. Due to the precise servo electric control, the dimensional consistency of the products is greatly improved, resulting in a lower scrap rate. The overall equipment combines powerful performance with precise execution, making it a cost-effective high-end injection molding machine.

3. Key Maintenance Points for the HXYD Hybrid Injection Molding Machine

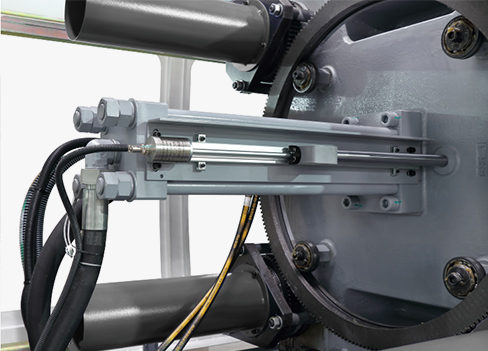

Operation of the HXYD hybrid injection molding machine requires careful coordination and adjustment of the servo and hydraulic systems. Operators should set reasonable injection speed, pressure curves, and clamping force according to different processes to ensure stable switching between the two systems during operation. For maintenance, regularly check the operating status of the servo motor, the cleanliness of the hydraulic oil, and whether the oil temperature control is normal; and keep the guide rails and mold contact surfaces clean. Due to the high precision of the hybrid structure, regular sensor calibration and control system backups should be performed to ensure long-term stable operation of the equipment.

HXYD Hybrid Injection Molding Machine Maintenance Checklist:

| Maintenance Area | Key Tasks | Frequency | Critical Notes |

| Daily Checks | |||

| Hybrid System Verification | Check electro-mechanical/hydraulic synchronization | Each shift | Monitor energy consumption patterns |

| Servo Motor Inspection | Check for abnormal noise/vibration in electric drives | Daily | Pay attention to braking systems |

| Weekly Maintenance | |||

| Energy Recovery System | Inspect capacitors and power regeneration components | Weekly | Verify proper energy feedback |

| Dual Power Transmission | Check belt tension in electric/hydraulic systems | Weekly | Differentiate maintenance for each system |

| Monthly Tasks | |||

| Hybrid Control System | Calibrate pressure/speed transition points | Monthly | Optimize electric-hydraulic handoff |

| Precision Components | Inspect electric injection drive mechanisms | Monthly | Check ball screws and linear guides |

| Quarterly Procedures | |||

| Hydraulic-Electric Balance | Test and adjust power distribution | Quarterly | Optimize based on production needs |

| Specialized Lubrication | Service electric drive components | Quarterly | Use conductive grease where required |

| Annual Maintenance | |||

| Comprehensive Diagnostics | Full system performance evaluation | Annually | Include energy efficiency audit |

| Safety System Recertification | Test all hybrid-specific safeguards | Annually | Verify redundant systems |

4. FAQ: Common Questions about the HXYD Hybrid Injection Molding Machine

Q1: What is the difference between a hybrid injection molding machine and a fully hydraulic machine?

A1: Hybrid machines use a combination of servo electric and hydraulic systems, resulting in faster speed, higher precision, and more significant energy savings, while fully hydraulic machines are characterized by strong stability but higher energy consumption.

Q2: Is the energy saving effect of the hybrid injection molding machine significant? A2: It's very clear that it generally saves 30%-60% energy compared to traditional hydraulic presses, depending on the product and process requirements.

Q3: Is the equipment suitable for thin-walled products?

A3: Yes, it's very suitable. The servo-electric injection system has high-speed response capabilities, enabling rapid mold filling, making it ideal for high-flow and thin-walled part production.

Q4: Is maintenance complicated?

A4: No, it's not complicated. The servo system requires minimal maintenance over long periods, and the hydraulic components only require periodic checks of oil quality and seals. The operating interface also provides maintenance reminders.

Q5: Does it support automation and smart factory integration?

A5: Yes, it supports seamless integration with robots, in-mold assembly, MES systems, etc., to build intelligent production lines.