Double Color Injection Molding Machine manufacturers

A brief introduction of two-color machine:

Two-color injection molding machines can process two type of raw materials (or two material of different colors) into one in one injection molding process. After the first material injection, the mold clamping part opens first, and then the mold is rotated 180° using the rotating structure of the injection machine, and then the mold is closed and the second injection is carried out with a raw material of different color or different raw materials (covering material) than the first injection.

Characteristics of two-color machine:

a. We have mixed two-color machine and clear two-color machine respectively for products of fusing colors and products of two distinct colors. It is all of high quality for our customer to choose according to their requirement and ideal products.

b. With major and minor two injection components that can inject synchronously and alternately through professional computer control system operate two screw bars, the plastic products can have a stunning color.

c. Costs an be reduced cause the charging and injection unit of our machine is optimized to save as much raw materials as they can, also the servo motor we adopted ca also save you 80% of power at most.

d. The range of the product that the two-color machine can produce is wide, mixed-color products like shoes, buttons, combs, etc. Sandwich color products can also be produced like plastic brushes, mugs and so on.

e. This machine can be widely used for many raw materials like PP, PE, PS in two color forming.

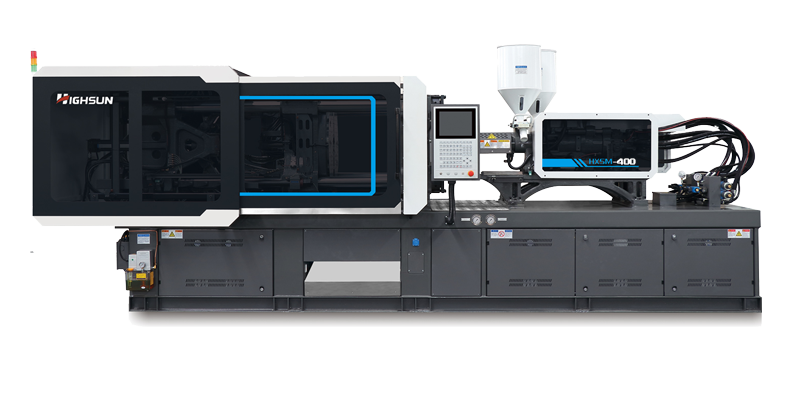

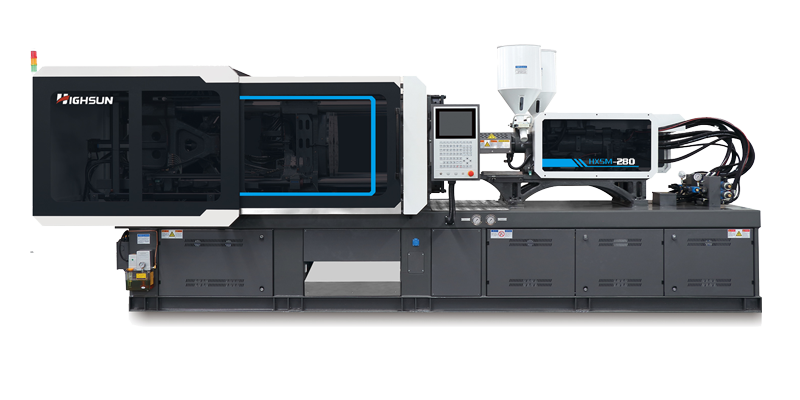

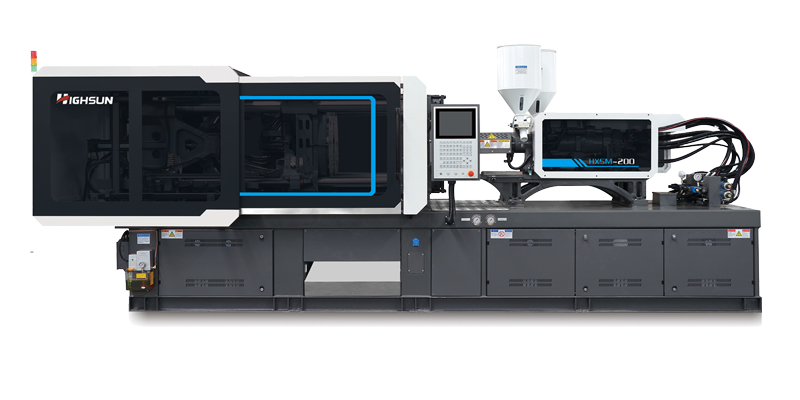

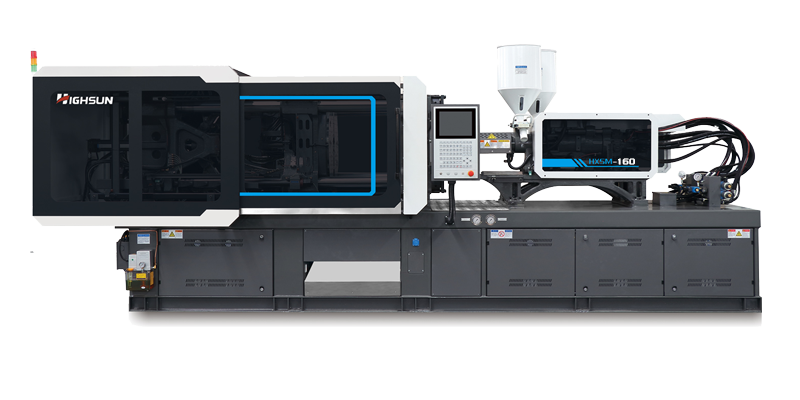

Ningbo Beilun Highsun Machinery Co., Ltd, established in 1973, is a leading

Double Color Injection Molding Machine manufacturers and

Two Color Injection Molding Machine Factory in China, with over 48 years of experience, Professional

Double Color Injection Molding Machine and other types of injection molding machines, equipped with advanced CNC machining system (CNC utilization rate: more than 83%). Achieve mass production and partial assembly line operation. As one of the top 5 plastic injection molding machine enterprises in China issued by China Machinery Industry Federation (CMIF). We produce 7,000 machines per year, and have the world's most advanced processing equipment and machining workshops. 90% of the mechanical components including the basic structure are produced in-house, which absolutely guarantees faster delivery; strict quality inspection system includes three Coordinate Measuring Machine (CMM) and MSA system to achieve closed-loop control of QA system, higher level of quality and service assurance.

English

English Español

Español عربى

عربى русский

русский