The automotive industry is the third most important consuming sector of polymers after packaging and building & construction. Therefore, changes in the material usage can have major implications on polymer demand and the financial performance of polymer producers. In this article, we explain how material usage trends are likely to evolve and what impact will electric vehicles have on polymer consumption.

The role of plastic in the design and manufacturing of automotive vehicles has never been more essential, with stringent regulations and changing consumer habits driving demand for more affordable, lightweight, and fuel-efficient vehicles. Fuel efficiency has become one of the most important features in automotive vehicle design due to the rising fuel prices and stricter environmental regulations. This, combined with high demand for automotive vehicles as well as rising disposable income in emerging economies will continue to drive demand for plastics in the automotive industry. However, while some materials may win from recent changes in the automotive industry, others will find themselves on the losing side, spelling serious implications for plastic.

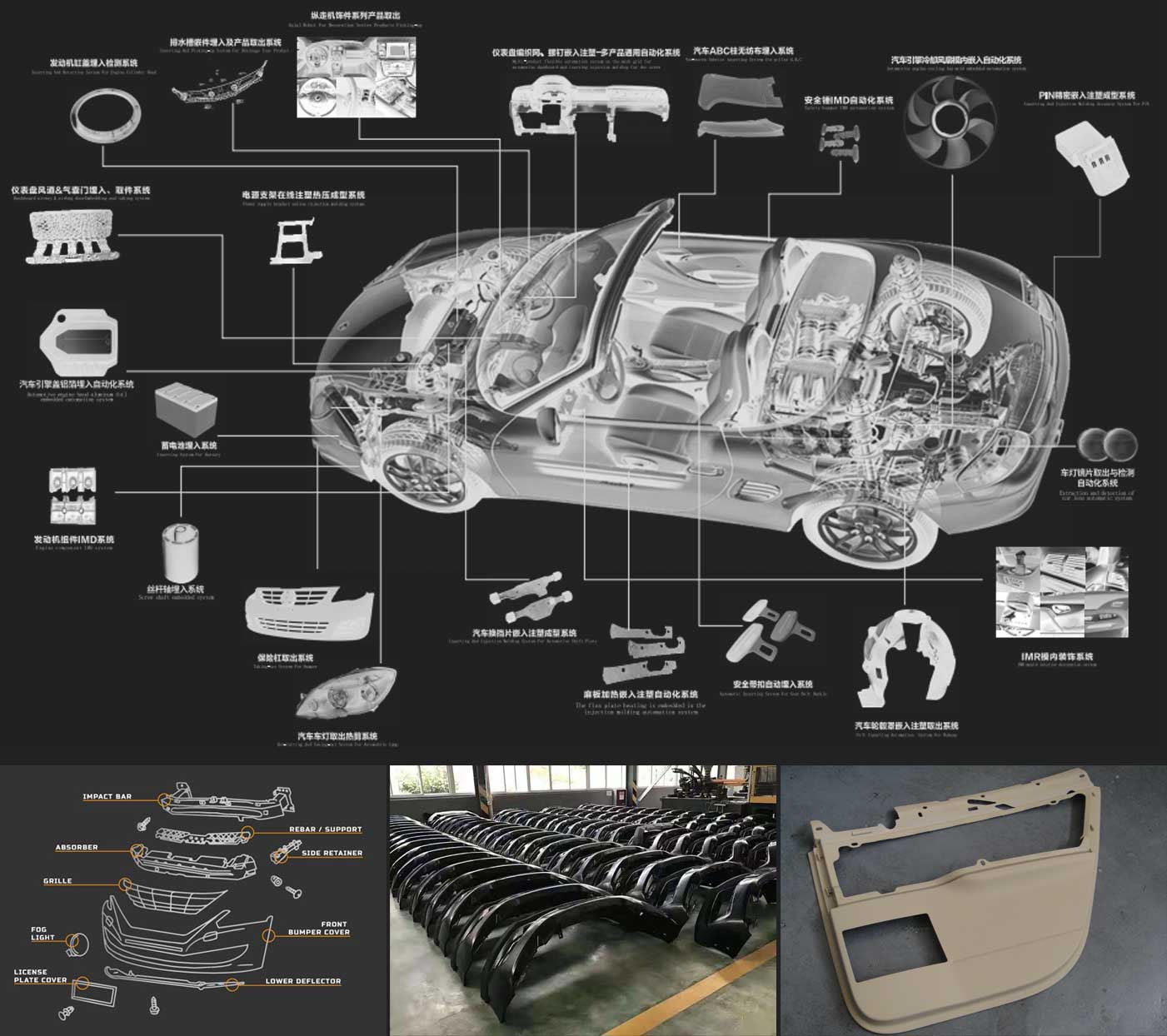

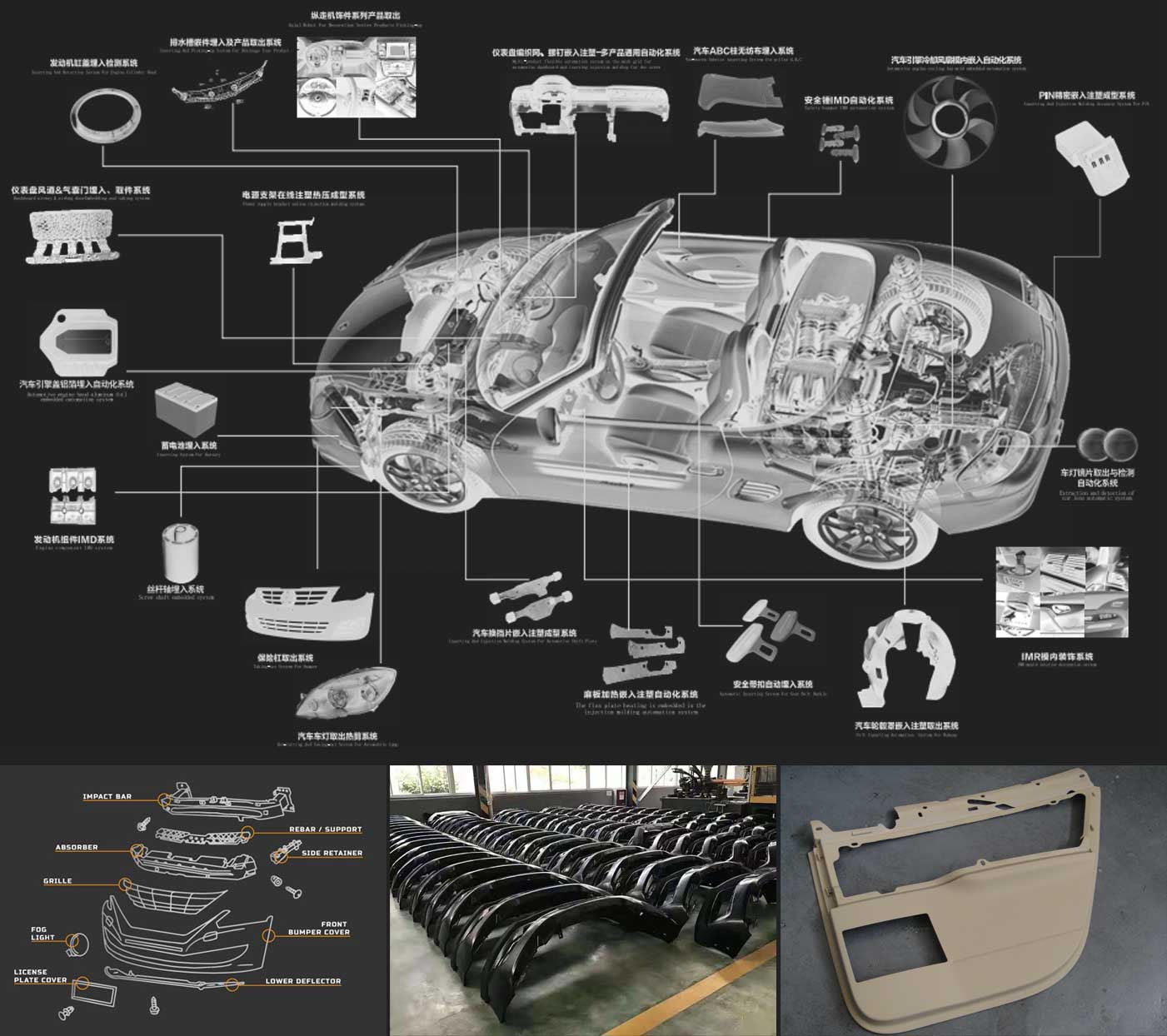

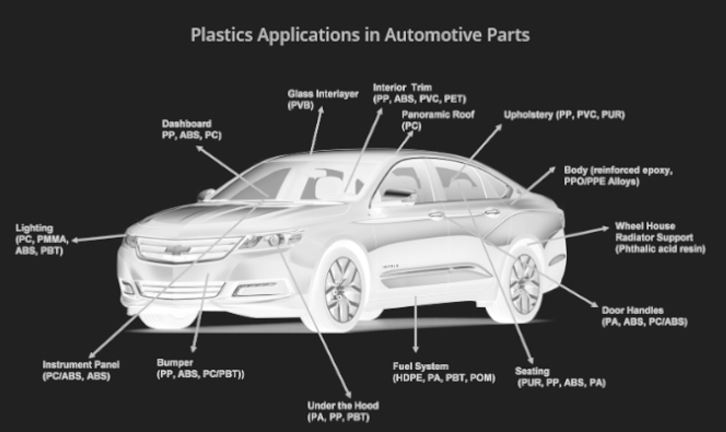

Currently, there are about 30,000 parts in a vehicle, out of which 1/3 are made of plastic. In total, about 39 different types of basic plastics and polymers are used to make an automobile. More than 70% of the plastic used in automobiles comes from four polymers: polypropylene, polyurethane, polyamides and PVC. Plastic has become one of the key materials required for the structure, performance, and safety of automobiles in recent years, with growth in plastic consumption being driven by light weighting trends for fuel efficiency and consequently lower greenhouse gas emissions. The high absorption properties of plastics also allow the vehicle to meet stricter safety standards, while the use of engineering plastics allows for minimization of the mass of parts used in vehicles as they offer more design freedom compared to metals.

Application: Lighting(PC, PMMA,ABS ,PBT) , Bumper (PP,ABS,PC/PBT), Door Handles (PA,ABS ,PC/ABS), Seating (PUR, PP,ABS,PA), Interior trim(PP,ABS,PVC,PET)