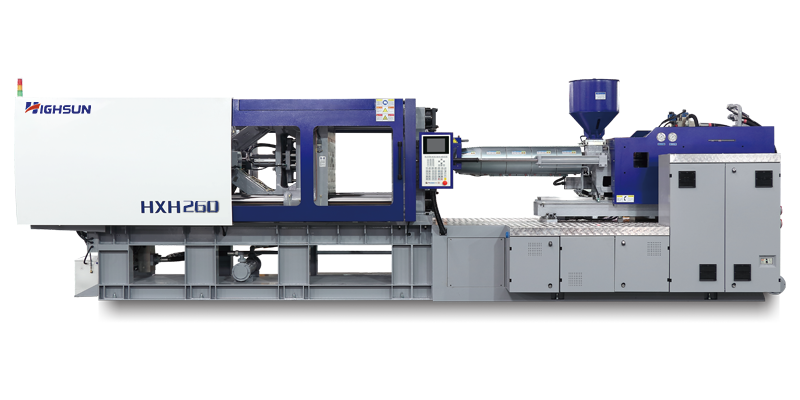

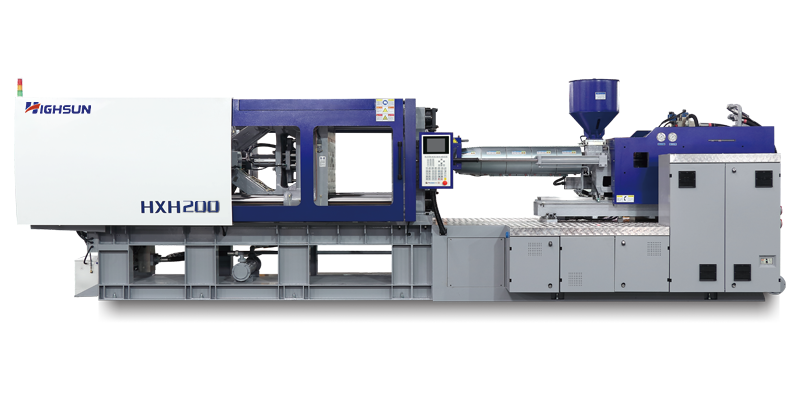

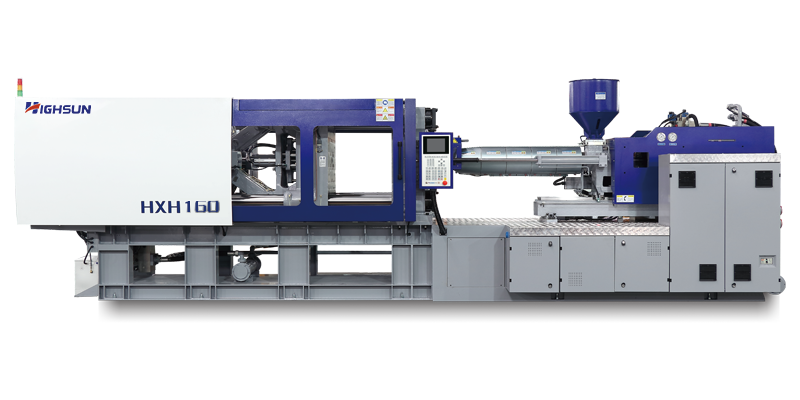

High Speed Injection Molding Machine manufacturers

As the earliest high-speed machine R&D team in China, Highsun insists on innovation, after years of research and improvement, has succuessfully designed a machine with excellent performance in terms of motion characteristics, machine precision, and service life.

Widely used in packaging , medical , 3C electronic large-area products and nylon cable ties, etc.

☑Larger space between tie-bar

☑Lower energy consumption

☑Lighter product weight

☑Lower maintenance cost

Single-cylinder injection structure greatly reduces the volume and pressure of the returned oil during injection,

Improving the response speed of the machine

Reducing energy consumption during injection.

Super energy

saving- 70% saving compare

ordinary heating band;

Faster heating rate- 15 mins

Better heat preservation

Longer service life

Easier to install

▶Optimized toggle structure with best stress analysis

▶Higher strength

▶More stable

▶Longer service life

Mold Position Monitoring--Magnetostrictive displacement sensor

◆Rugged industrial displacement sensors

◆non-linear accuracy of ± 0.01%

Clamping and Opening Mold Control

Proportional directional valve control

Rapid acceleration

Stable high-speed operation,

Precise mold opening position contro

Servo Hydraulic System

Dual servo drive control- highly-efficient, energy saving and low noise .

Synchronization of mold opening and charging, faster cycle is possible

Lubrication System

Recyclable lubricating oil purifier is adopted,

it can recycle the used lubricating oil and performs impurity filtration,

oil-water separation, purification, automatic drainage,

and recycling to save lubricating oil.

Electrical Control System

The computer control system adopts CANbus, EtherCAT and other bus communication to realize full digital control.

The temperature control adopts a special control module with an accuracy of 1 degree.

With the power monitoring function, it can accurately monitor the current production energy consumption in real time.

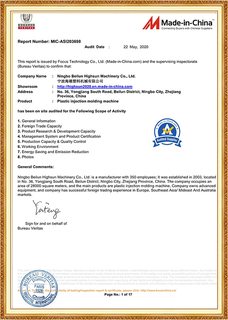

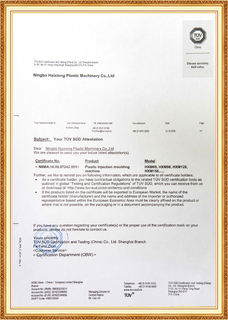

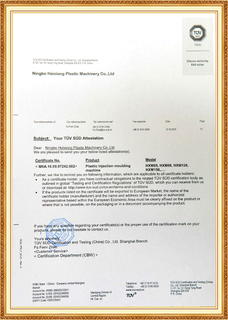

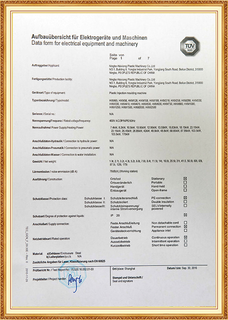

Ningbo Beilun Highsun Machinery Co., Ltd, established in 1973, is a leading

High Speed Injection Molding Machine manufacturers and

High Speed Injection Molding Machine Factory in China, with over 48 years of experience, Professional

wholesale High Speed Injection Molding Machine and other types of injection molding machines, equipped with advanced CNC machining system (CNC utilization rate: more than 83%). Achieve mass production and partial assembly line operation. As one of the top 5 plastic injection molding machine enterprises in China issued by China Machinery Industry Federation (CMIF). We produce 7,000 machines per year, and have the world's most advanced processing equipment and machining workshops. 90% of the mechanical components including the basic structure are produced in-house, which absolutely guarantees faster delivery; strict quality inspection system includes three Coordinate Measuring Machine (CMM) and MSA system to achieve closed-loop control of QA system, higher level of quality and service assurance.

English

English Español

Español عربى

عربى русский

русский