HXH200: HXH high-speed injection molding machine

It is equipped with an intuitive, concise and easy-to-operate interface. The layout of the operation buttons is designed with full consideration of ergonomic principles, enabling operators to quickly get familiar with and start using it. It is convenient for operations such as parameter setting, real-time equipment monitoring, and troubleshooting, which greatly reduces the difficulty of operation and effectively improves work efficiency. For instance, the operation interface features a large-sized high-definition display screen, making all kinds of parameters clear and legible, and the operation procedures are simple and easy to understand, so that even novice operators can quickly master them.

ENG

ENG  English

English русский

русский Español

Español Português

Português عربى

عربى

+86-188 6861 6288

+86-188 6861 6288 haixiong@highsun-machinery.com

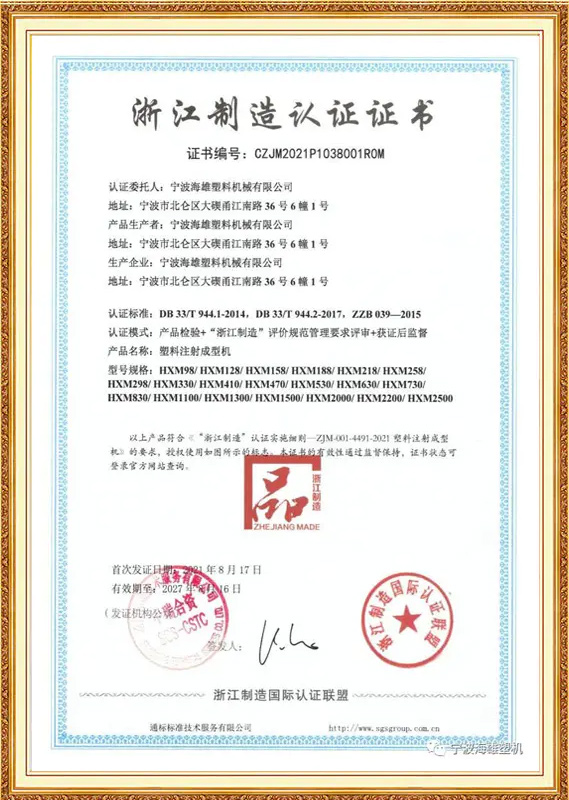

haixiong@highsun-machinery.com No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China

No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China