SP SMART POWER HIGH PERFORMANCE MACHINE manufacturers

1.CLAMPING UNIT

A: The optimized designed 5-point toggle clamping structure has a central clamping effect and bigger openingstroke, lower axis-pin contact stress, more suitable for deep cavity product molding. The machine dry cycle is shorter.

B:The ultra-high rigidity square plate and tie-bar structure design caters to international mold design standards,improves mold adaptability, reduces principal stress,the plate force is more uniform, extends the life of tie-bar,and more effectively fit and protect the mold.

C:Optimized toggle structure improves the life of the machine and reduces the maintenance cost,the ejectionpart is equipped with a forced retracting device as standard,ejection stroke is longer,and the ejection positioncan be adjusted freely.

D:Side-mounted new mechanical safety structure, more convenient to operate and safer to use.

2.INJECTION UNIT

A:The injection base is made of integral castings.The newinjection structure has lower oil return resistance. Standardequipped with linear guide and electronic back pressurewith closed-loop function,which can reduce friction andmake the machine run more smoothly,and improve theaccuracy of repeated injection of products.

B:The design of the screw&barrel is optimized, electroplatingand bi-metal screw is standard, the wall thickness of the barrelis increased. The screw drive adopts a spline connection tomake the screw rotation force more evenly. The plasticizingcapacity and injection accuracy is greatly improved.

3.HYDRAULIC SYSTEM

A:The system pressure is increased to 17.5Mpa, the hydraulic system flow is increased andupgraded,and the low inertia high response servo system is adopted. It has the characteristicsof large pipe diameter,short pipe length,fast response,low noise, strong power,etc., and theinjection speed is fully improved.

B:The non-welded tube effectively avoids oil leakage; the self-sealing suction filter is more conve-nient for maintenance, and the high-precision bypass filter improves the cleanliness of the oil.

C:Fully automatic thin oil lubrication system design ensures the full coverage of lubrication, andmore smooth. Built-in lubrication pump design saves rack space and improves transportationsafety.

4.ELECTRICAL CONTROL SYSTEM

A: The new generation of servo power system is moreenergy-saving and environmentally friendly;the powerof the oil pump motor drive system is increased, whichshortens the product molding cycle and broadens themolding process.

B:The advanced electronic control system with biggeroperation panel(12" of displayer),works more stableand reliable, the operation accuracy and safety protec-tion level are higher.

The function of the intelligent Internet of managementsystem conforms to the industry 4.0 trend and opens anew era of smart factories

C: The rotary switch supports power-off when the door isopened, and the new safety upgrade conforms to theCE standard.

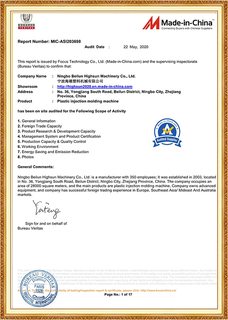

Ningbo Beilun Highsun Machinery Co., Ltd, established in 1973, is a leading

SP SMART POWER HIGH PERFORMANCE MACHINE manufacturers and

SP SMART POWER HIGH PERFORMANCE MACHINE Factory in China, with over 48 years of experience, Professional

Custom SP SMART POWER HIGH PERFORMANCE MACHINE and other types of injection molding machines, equipped with advanced CNC machining system (CNC utilization rate: more than 83%). Achieve mass production and partial assembly line operation. As one of the top 5 plastic injection molding machine enterprises in China issued by China Machinery Industry Federation (CMIF). We produce 7,000 machines per year, and have the world's most advanced processing equipment and machining workshops. 90% of the mechanical components including the basic structure are produced in-house, which absolutely guarantees faster delivery; strict quality inspection system includes three Coordinate Measuring Machine (CMM) and MSA system to achieve closed-loop control of QA system, higher level of quality and service assurance.

English

English Español

Español عربى

عربى русский

русский