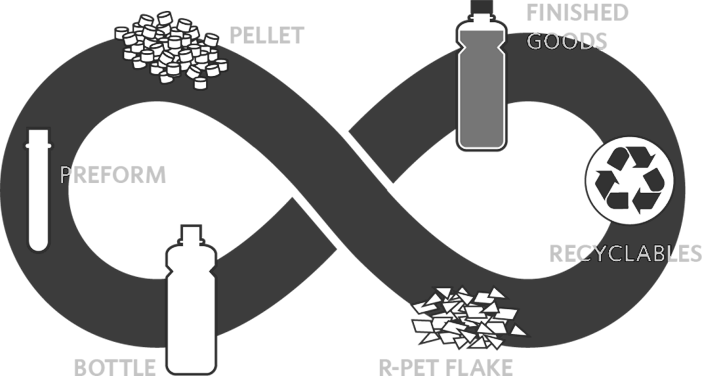

PET(polyethylene terephthalate) possesses packaging properties that make it preferable over other packaging technologies. Certain beneficial properties of PET packaging are high transparency, shiny surface, good stability, high-pressure resistance, good barrier properties, and light weight. It is best known as a clear plastic that is widely used for packaging foods and beverages, especially convenience-sized soft drinks, juices and water.

Bottles and other rigid plastic packaging made from polyethylene terephthalate (PET) are continuing to grow in demand despite pressure over their environmental impact a recent Smithers study reveals. While Covid-19 is the immediate challenge, new recycling technologies and alternative feedstocks will be increasingly important over the five years to 2026. The PET Packaging market was valued at USD 55.52 billion in 2020 and is expected to reach USD 74.2 billion by 2026, at a CAGR of 3.7-5% over the forecast period 2021 – 2026

Application: Water; Fruit juice; Beer; Other drinks; Food; Household cleaning products; Cosmetics & personal care; Pharmaceutical & medical.

Application: Water; Fruit juice; Beer; Other drinks; Food; Household cleaning products; Cosmetics & personal care; Pharmaceutical & medical.

-Stronger power system of enlarged motor & pump

-Stronger hydraulic system with specially design for PET

-Stronger torque of plasticizing motor to improve charging efficiency.

-Stronger ejection system with enlarged ejecting force and stroke for quicker and stronger ejection of multicavity of PET products.

-Bigger base frame for enlarged injection unit

-Bigger L/D of screw with highly effective intermixing structure specially design for PET in case of shrinkage deforming, and improve the transparency.

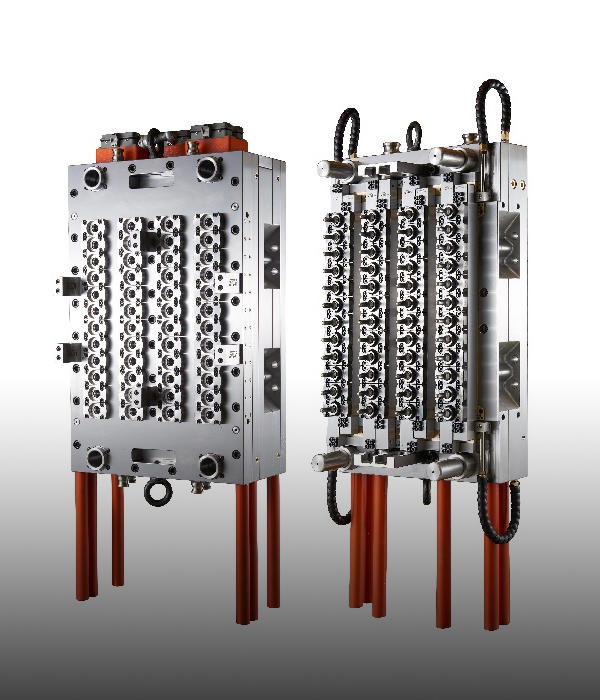

-Bigger water manifold for quicker cooling of the mould

1. Air-cooled mold dehumidifier

2.PET material dehumidifier

3. PET material dryer

4. Hopper autoloader

5. Master batch doser

6.Water chiller

7. Robot

8. Conveyor

9. Granulator for recycling

10. PET-PREFORM MOULD