SP200: SP smart power injection molding machine

The SP200 injection molding machine, with many advantages such as high-efficiency plasticization, precise mold clamping, intelligent control, and energy conservation and consumption reduction, demonstrates powerful application value in multiple industries, including packaging, electronics and electrical appliances, and automotive parts. In the market competition, its unique performance makes it stand out, providing enterprises with efficient, stable, and high-quality injection molding solutions, helping enterprises to improve production efficiency, reduce costs, and enhance product quality.

ENG

ENG  English

English русский

русский Español

Español Português

Português عربى

عربى

+86-188 6861 6288

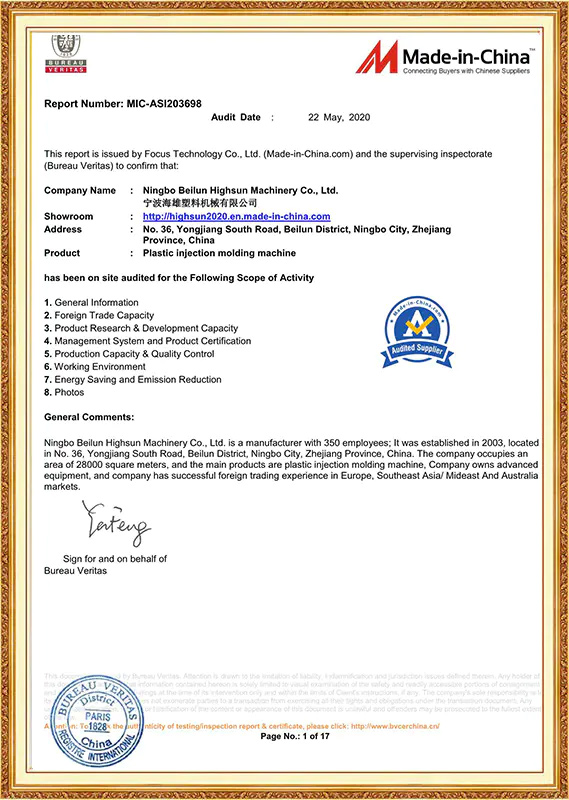

+86-188 6861 6288 haixiong@highsun-machinery.com

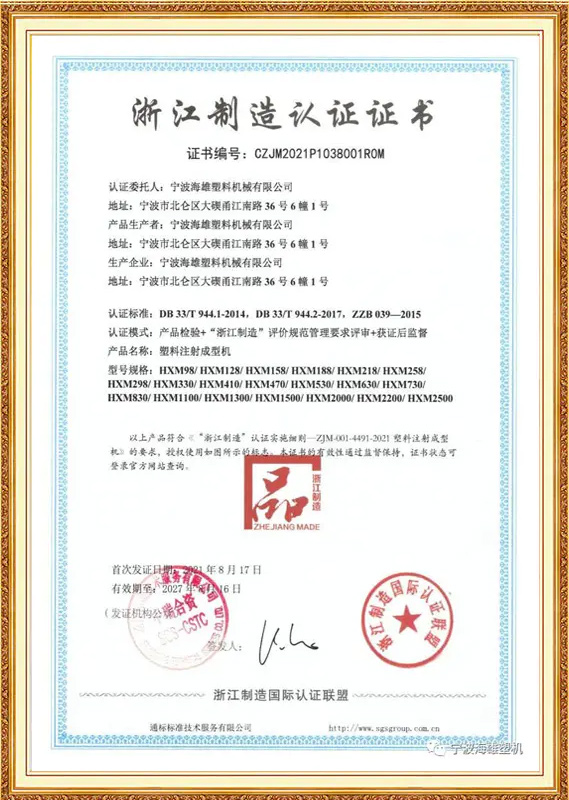

haixiong@highsun-machinery.com No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China

No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China