SP160: SP smart power injection molding machine

The plastifying components with optimized design have greatly improved the machine's plastifying ability and injection speed. The screw drive adopts a spline connection, which makes the screw evenly stressed during rotation and ensures the stable plastification of the material. The injection movement part uses linear guides for orientation, which significantly reduces the friction during movement, making the injection process smoother and more efficient. This design can quickly and uniformly plastify the material and precisely inject it into the mold cavity, improving production efficiency while ensuring product quality. For example, when producing small and precise plastic parts, it can quickly complete the material filling and ensure that the weight and dimensional accuracy of each part are highly consistent, meeting the stringent requirements for product accuracy.

ENG

ENG  English

English русский

русский Español

Español Português

Português عربى

عربى

+86-188 6861 6288

+86-188 6861 6288 haixiong@highsun-machinery.com

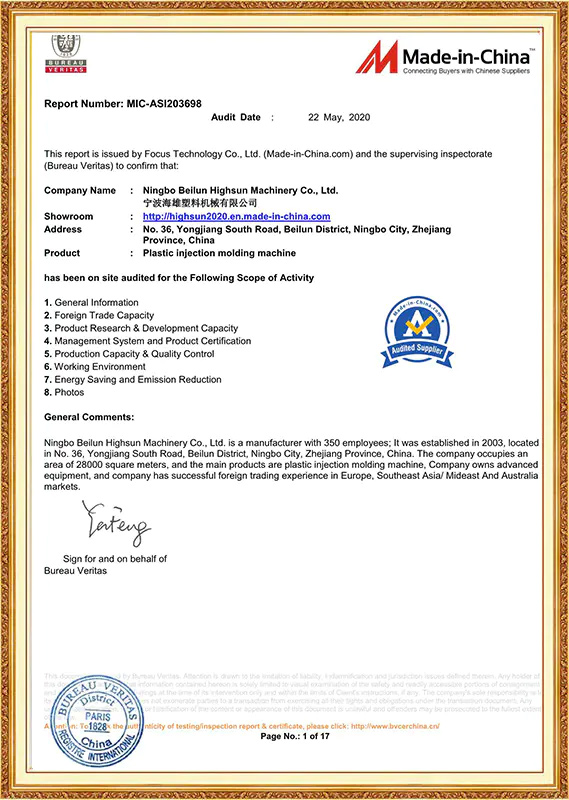

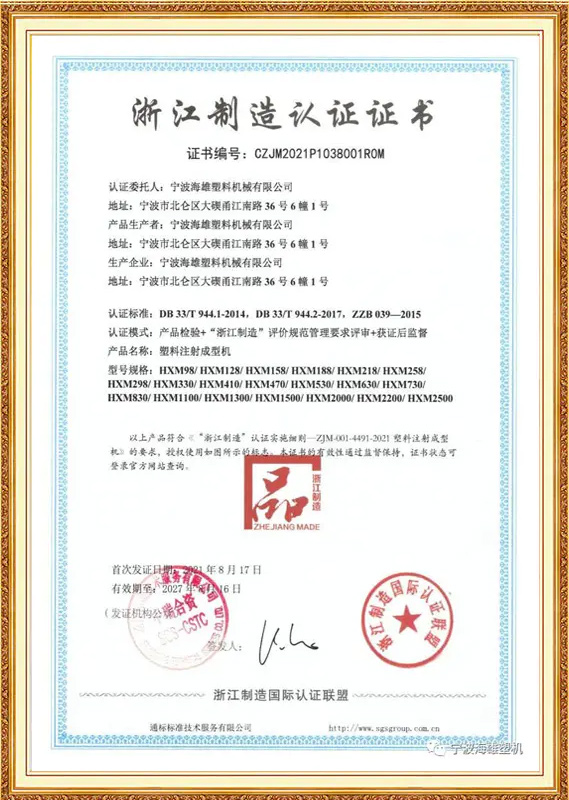

haixiong@highsun-machinery.com No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China

No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China