Choose Based on Product Requirements First — Not Machine Price The right PVC injection molding machine is the one that matches your product size, PVC formulation, and production volume. Clamping force...

READ MORE

|

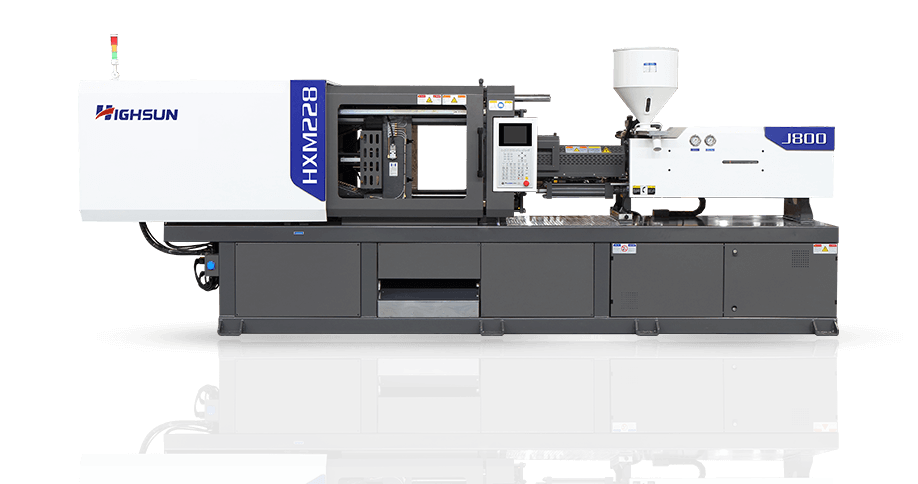

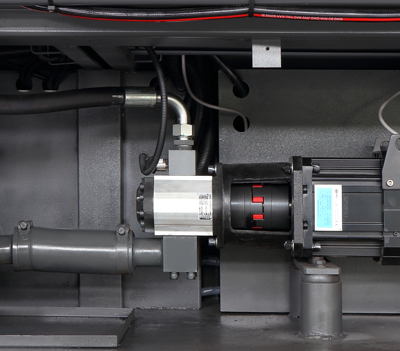

Intelligent Servo Drive System (Core Technology) Design Highlights: Permanent Magnet Synchronous Servo Motor + Closed-Loop Vector Control. ● Power-on-Demand (0 Standby Consumption) vs. Traditional Fixed-Displacement Pump Continuous Energy Waste. ● 40%+ Faster Dynamic Response (Millisecond-Level Torque Control). ● Motor Efficiency >95% (Asynchronous Motors: 60-70% Only). |

|

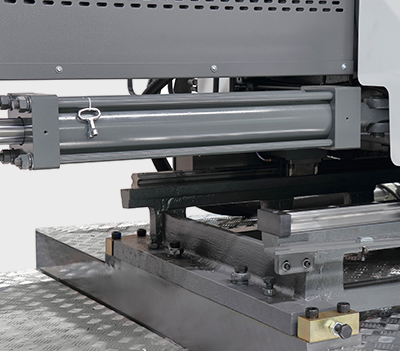

T-Type High-Rigidity Platen System (Core Anti-Deformation Technology) Structural Innovations: ● Monobloc T-box Tie-bar Housing (replaces traditional straight-plate platens). ● Multi-rib Reinforcement Design (patented stress distribution optimization) Technical Advantages: Permanent Magnet Synchronous Servo Motor + Closed-Loop Vector Control. ● Leap in deformation resistance: Clamping deflection <0.02mm (Traditional C-frame: ≥0.1mm) ● Fundamentally extends lifespan: 90% reduction in tie-bar fracture risk (stress concentration eliminated) ● Guarantees efficient production: Enables 30% faster mold opening/closing (vibration suppression via rigid support) |

|

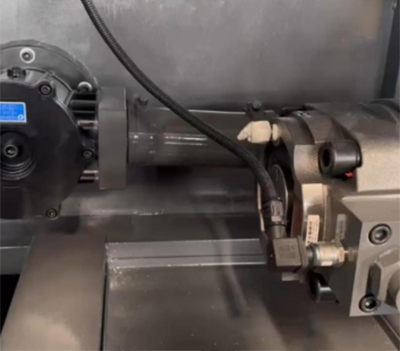

High-Rigidity Linear Guide System (Precision Motion Foundation) Design Breakthrough: Full Moving Plate Linear Guides replace traditional sliding guides. Core Advantages: Precision Leap: Reduces motion deviation, ensuring precise linear motion trajectory of the screw and injection unit. Enhances injection molding consistency with repeat positioning accuracy of ±0.01mm. Increase service life: Guide material and precision ball design minimize wear, extending service life to 5–10 times that of sliding guides, reducing replacement frequency. Extended Energy Savings: Coefficient of rolling friction (approx. 0.001–0.003) is significantly lower than sliding friction (approx. 0.05–0.2), decreasing drive motor load and saving energy (typical energy reduction: 10%–30%). |

|

Thermal Management Optimization System (Stability Assurance Core) Temperature Control Innovations: ● Permanent Magnet Synchronous Servo Motor + Closed-Loop Vector Control. ● Dual-circuit oil temp control (±1°C accuracy). ● Barrel zone PID heating (15% energy savings). |

|

Smart Hydraulic Maintenance-External Self-Locking Filter (HXM368+) ● Tool-Free Quick Replacement. ● Less Maintenance Time. |

Choose Based on Product Requirements First — Not Machine Price The right PVC injection molding machine is the one that matches your product size, PVC formulation, and production volume. Clamping force...

READ MORETroubleshooting Common Issues in PET Preform Injection Molding Machines PET preform injection molding machines are vital for producing high-quality plastic bottles and containers. However, like all m...

READ MOREHow PVC Injection Molding Machines Enhance Production Efficiency PVC injection molding machines can significantly enhance production efficiency by streamlining manufacturing processes, improving prod...

READ MOREThe direct answer is yes: the HXM Servo Injection Molding Machine is designed to deliver high precision, lower energy consumption, and stable production performance, making it ideal for manufacturers ...

READ MOREThe HXYD hybrid injection molding machine represents a significant evolution in manufacturing technology. Combining the strengths of electric and hydraulic systems, it provides an efficient and flexib...

READ MORE1. What is a HXM servo machine?

The HXM servo machine is a type of industrial automation equipment centered around a high-performance servo drive system, primarily used for precise position control, speed control, and torque control. Compared to traditional hydraulic or ordinary motor-driven equipment, HXM servo machines are known for their higher response speed, lower energy consumption, and stronger dynamic control capabilities. Their design typically includes a servo motor, servo drive, high-precision encoder, and optimized mechanical structure, and they are widely used in industries such as injection molding, die casting, packaging, and electronic assembly.

We are a professional China HXM Servo Injection Molding Machine Manufacturers and HXM Servo Injection Molding Machine Factory, We specialise in producing and marketing high-grade precision plastic injection molding machines under the "HIGHSUN" brand.

2. Advantages and Features of HXM Servo Machines

HXM servo machines offer several advantages, including high energy efficiency, intelligence, precision, and reliability. Through a servo-driven energy-saving system, power consumption can be reduced during operation, achieving energy savings of 30% to 70% compared to traditional hydraulic equipment. Their fast response speed and short acceleration/ deceleration times effectively improve production efficiency. The intelligent control system supports adaptive adjustment of various process parameters, making operation more intuitive; at the same time, remote monitoring and fault diagnosis functions significantly reduce maintenance costs and downtime risks. The equipment is highly stable and can maintain long-term operation in complex, continuous, and high-intensity industrial environments.

The HXM servo machine adopts a modular structure, consisting of a power system, control system, cooling system, and high-rigidity frame. The servo power unit adjusts the output in real time through a closed-loop feedback system, ensuring low vibration and low noise even during high-speed operation. Its encoder can achieve micron-level positioning accuracy, providing higher stability for fine machining or high-repetition cycle operations. Furthermore, the HXM servo machine's body structure uses high-strength alloy materials and an optimized frame layout, significantly improving overall durability and impact resistance.

3. Maintenance Points for HXM Servo Machines

Maintenance of HXM servo machines is relatively simple, but it still needs to be performed according to specifications. This mainly includes: regularly checking the servo motor temperature, lubrication status, and cable wear; keeping the inside of the control cabinet clean and well-ventilated; regularly calibrating the encoder to ensure positioning accuracy; and monitoring servo drive alarm records to troubleshoot potential faults in advance. Good maintenance not only extends the equipment's lifespan but also ensures that it continues to operate at its best.

| Maintenance Item | Procedure | Frequency | Precautions |

| Visual Inspection | Check for cracks, deformation, corrosion, or foreign objects on the housing. | Daily/Weekly | Stop operation if damage is found to prevent internal component failure. |

| Cable & Connector Check | Inspect power, encoder, and signal cables for looseness or wear. | Weekly/Monthly | Ensure secure connections to avoid short circuits or signal interference. |

| Cooling & Ventilation | Clean cooling fans and vents to prevent dust buildup. | Monthly | Power off before cleaning to avoid injury from moving parts. |

| Bolt Tightening | Inspect and tighten mounting screws, coupling bolts, etc. | Every 6 months | Use a torque wrench to meet specified values. |

| Vibration & Noise Test | Listen for abnormal noise/vibration during operation. | Daily/Periodic | Investigate immediately if irregularities occur (e.g., bearing or load issues). |

| Parameter Monitoring | Monitor current, temperature, and position error via software. | Each operation | Log trends; adjust parameters if deviations are detected. |

| Environmental Check | Ensure ambient temperature (0-40掳C), humidity (<80%), and no corrosive dust. | Daily | Add protective measures (e.g., seals, air conditioning) in harsh conditions. |

| Load Inspection | Check for overload, misalignment, or mechanical binding. | Monthly | Excessive load reduces motor lifespan. |

| Professional Service | Schedule deep inspections (e.g., bearing wear, PCB aging) by technicians. | Every 1-2 years | Avoid disassembling precision components without expertise. |

4. FAQ: Frequently Asked Questions about the HXM Servo Machine

Q1: What are the advantages of the HXM servo machine compared to traditional hydraulic presses?

A1: Lower energy consumption, lower noise, more precise movements, faster response, and support for intelligent control and remote monitoring.

Q2: Is the HXM servo machine suitable for 24-hour continuous production?

A2: Yes, its servo system has high stability and durability, making it very suitable for long-term, high-intensity operation.

Q3: Is the energy-saving effect of the HXM servo machine significant?

A3: Compared with traditional equipment, the energy saving rate can reach 30%~70%, depending on the process and load conditions.

Q4: What should I do if the equipment shows an alarm or error?

A4: You can check the alarm code through the control system for targeted troubleshooting; you can also perform remote diagnostics or contact professional technical support.

Q5: Is customization supported?

A5: Yes, we support customization of the control system, power configuration, and structural dimensions according to industry needs to meet diverse application scenarios.