Choose Based on Product Requirements First — Not Machine Price The right PVC injection molding machine is the one that matches your product size, PVC formulation, and production volume. Clamping force...

READ MORE

|

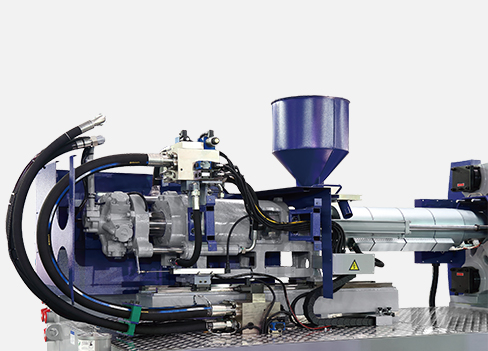

Low-energy Consumption Structural Design ● Single-cylinder injection structure greatly reduces the volume and pressure of the returned oil during injection. |

|

Super Save-energy

Saving- 70% saving compared to ordinary heating band.

● Faster heating rate- 15 mins

● Better heat preservation

● Longer service life

● Easier to install

|

|

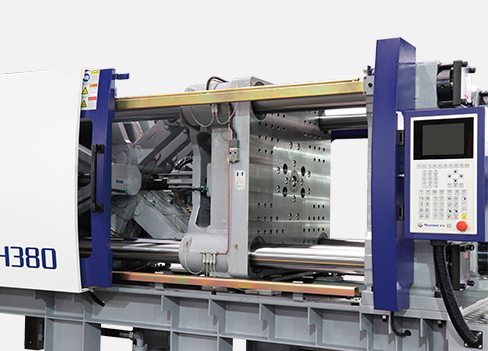

Clamping Unit ● Optimized toggle structure with great stress analysis |

|

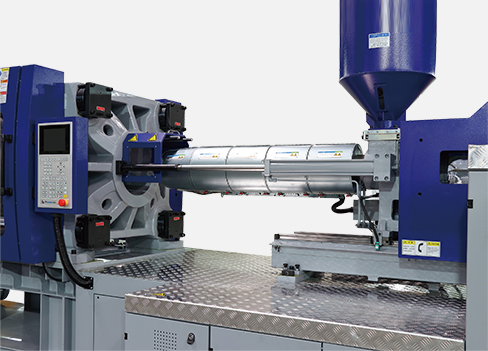

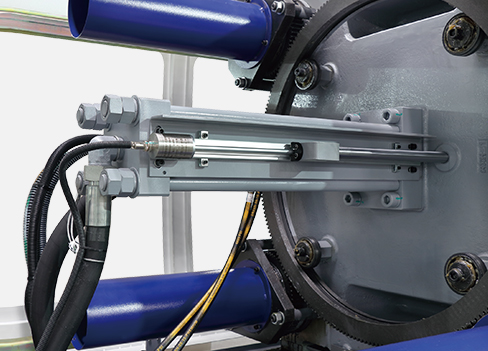

Magnetostrictive Non-Contact transducer ● A Revolutionary Innovation Zero Physical Friction: Technical Highlights: |

Choose Based on Product Requirements First — Not Machine Price The right PVC injection molding machine is the one that matches your product size, PVC formulation, and production volume. Clamping force...

READ MORETroubleshooting Common Issues in PET Preform Injection Molding Machines PET preform injection molding machines are vital for producing high-quality plastic bottles and containers. However, like all m...

READ MOREHow PVC Injection Molding Machines Enhance Production Efficiency PVC injection molding machines can significantly enhance production efficiency by streamlining manufacturing processes, improving prod...

READ MOREThe direct answer is yes: the HXM Servo Injection Molding Machine is designed to deliver high precision, lower energy consumption, and stable production performance, making it ideal for manufacturers ...

READ MOREThe HXYD hybrid injection molding machine represents a significant evolution in manufacturing technology. Combining the strengths of electric and hydraulic systems, it provides an efficient and flexib...

READ MORE1. What is a high-speed precision injection molding machine?

A high-speed precision injection molding machine is a type of injection molding equipment characterized by high-speed injection, rapid molding, and high-precision control. It is primarily used for producing thin-walled, complex-shaped plastic products with extremely high dimensional requirements. Compared to ordinary injection molding machines, high-speed precision injection molding machines have higher injection speeds, faster clamping response, and more stable pressure control, significantly improving production efficiency and product consistency. It is a key production equipment in industries such as electronic products, optical parts, medical devices, and automotive precision components.

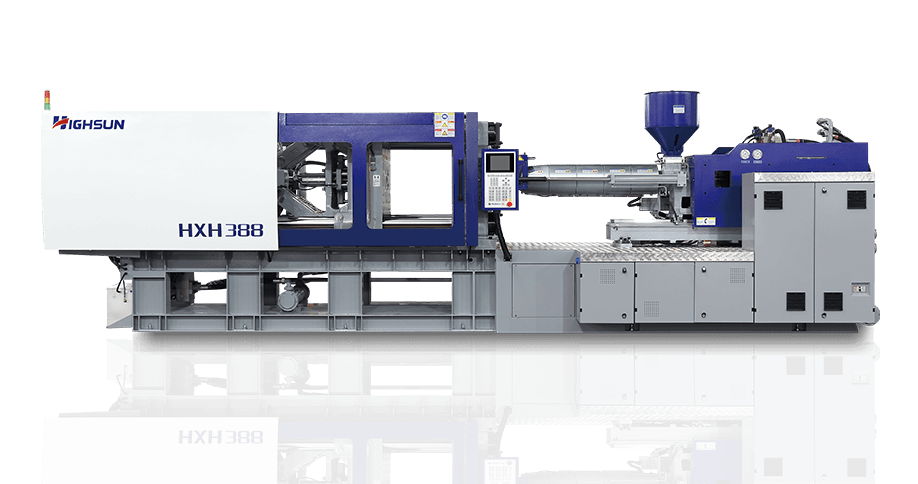

Ningbo Beilun Highsun Machinery Co., Ltd. is a professional China High Speed Precision Injection Molding Machine Manufacturers and High Speed Precision Injection Molding Machine Factory, We specialise in producing and marketing high-grade precision plastic injection molding machines under the "HIGHSUN" brand.

2. Advantages and Features of High-Speed Precision Injection Molding Machines

The biggest advantages of high-speed precision injection molding machines are their speed, precision, and stability. High injection speed improves molding efficiency, especially suitable for rapid mold filling of thin-walled products; high-precision pressure and speed control result in more stable product dimensions and fewer defects. The servo drive system reduces energy consumption, achieving energy saving and low-noise operation. Its high-speed clamping mechanism reduces the molding cycle, increasing overall production efficiency by 30%-70% compared to ordinary machines. At the same time, the equipment operates smoothly with low vibration, suitable for high-demand and high-repeatability production.

High-speed precision injection molding machines adopt a high-rigidity frame structure to ensure body stability during high-speed operation. The injection system mostly uses servo motors or high-speed servo hydraulic systems, which can complete injection and holding pressure actions in a very short time. The clamping mechanism is usually a high-response toggle structure or direct-pressure structure to ensure fast mold opening and closing and long service life.

3. Key Maintenance Points for High-Speed Precision Injection Molding Machines

The key maintenance points for high-speed precision injection molding machines are maintaining the cleanliness and stability of the transmission system and hydraulic system. Operators must strictly follow the process parameters to avoid deviations during high-speed injection that could lead to product defects. Daily checks include: screw wear, oil temperature and quality, sensor accuracy, cooling system water flow, and whether the mold clamping force is balanced. Maintaining good lubrication and regular calibration of the equipment can ensure that it maintains high speed and high precision during long-term operation.

High-Speed Precision Injection Molding Machine Maintenance Guide:

| Maintenance Area | Key Tasks | Frequency | Critical Notes |

| Daily Checks | |||

| Visual Inspection | Check for oil leaks, loose components, abnormal noises | Every shift | Tag and address issues immediately |

| Mold Condition | Inspect for wear, damage, and proper alignment | Every run | Proper alignment prevents flash and defects |

| Clamping Unit | Verify tonnage pressure and parallelism | Daily | Incorrect pressure affects part quality |

| Weekly Maintenance | |||

| Hydraulic System | Check oil level, filter condition, and hose integrity | Weekly | Maintain oil temperature at 45-55°C |

| Lubrication | Grease tie bars, ejectors, and moving parts | Weekly | Use manufacturer-recommended grease |

| Safety Systems | Test emergency stops and safety gates | Weekly | Never bypass safety devices |

| Monthly Tasks | |||

| Screw & Barrel | Inspect for wear and clean if needed | Monthly | Measure screw/barrel clearance |

| Electrical Components | Tighten connections, check for overheating | Monthly | Power off before inspection |

| Temperature Control | Verify heater bands and thermocouples functionality | Monthly | Uneven heating causes quality issues |

| Quarterly Procedures | |||

| Hydraulic Oil | Sample and analyze oil quality | Every 3 months | Change if contamination exceeds limits |

| Servo Motors | Check brushes, encoders, and cooling | Quarterly | Monitor for unusual vibrations |

| Annual Maintenance | |||

| Complete Overhaul | Thorough inspection of all mechanical and electrical systems | Annually | Best performed during scheduled downtime |

| Alignment Checks | Verify machine and mold platens alignment | Annually | Misalignment reduces machine lifespan |

| Software Updates | Update control software and backup parameters | Annually | Verify compatibility before updating |

4. Common Questions about High-Speed Precision Injection Molding Machines

Q1: What are the main differences between a high-speed precision injection molding machine and an ordinary injection molding machine? A1: Faster injection speed, more precise pressure control, shorter molding cycle, and higher product accuracy; mainly used for high-end product manufacturing.

Q2: Is the equipment energy-efficient?

A2: The servo motor and servo hydraulic system can significantly reduce energy consumption, saving approximately 20%-60% compared to traditional injection molding machines.

Q3: What thin-walled products are suitable for this machine?

A3: Such as mobile phone cases, thin-walled containers, light guide plates, and precision electronic components – products that require extremely high speed and fluidity.

Q4: Is maintenance troublesome?

A4: No, the equipment uses an intelligent monitoring system that can provide advance warnings for maintenance tasks. Only regular checks of lubrication, oil quality, and sensor status are required.

Q5: Does it support integration with automated production lines?

A5: Yes, it can be seamlessly integrated with systems such as robotic arms, in-mold labeling, in-mold assembly, and automatic packaging to build a fully automated production line.