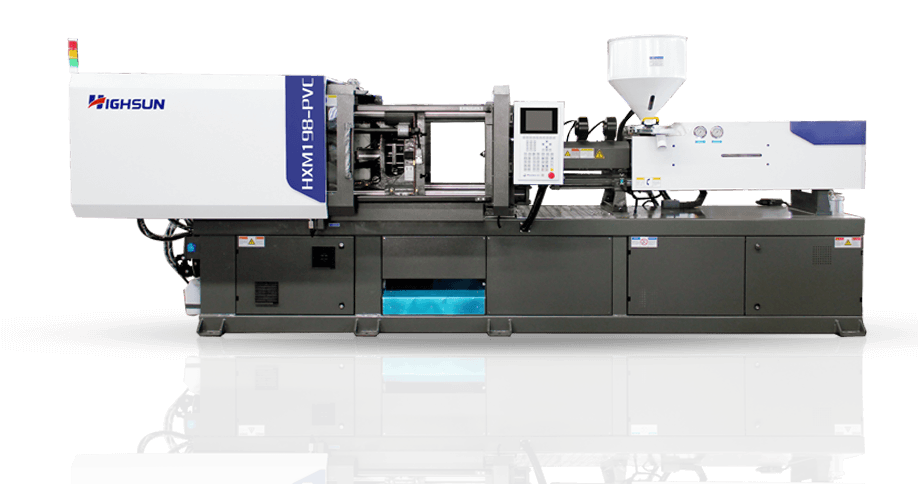

How PVC Injection Molding Machines Enhance Production Efficiency PVC injection molding machines can significantly enhance production efficiency by streamlining manufacturing processes, improving prod...

READ MORE

|

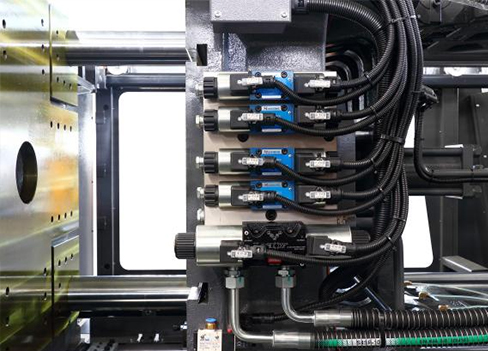

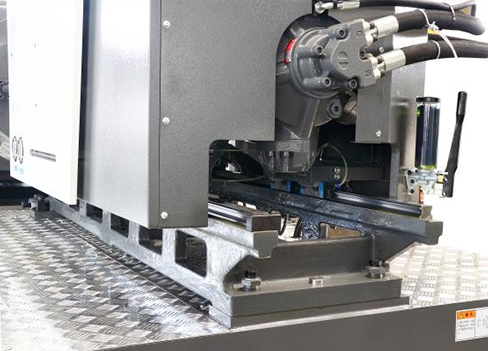

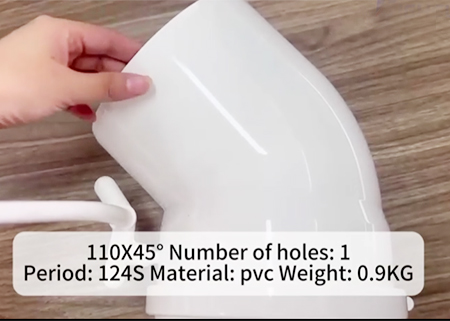

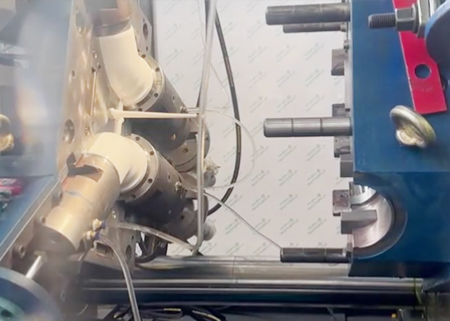

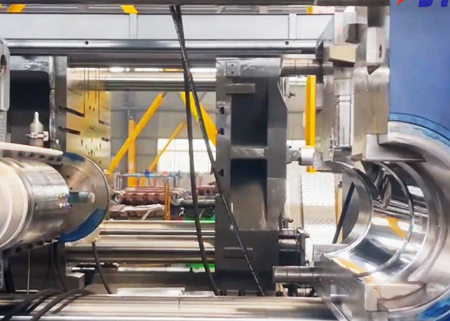

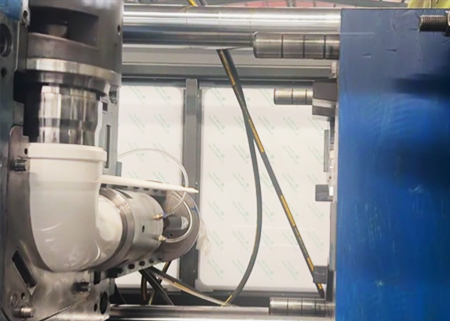

Standard Double Hydraulic Core-Pulling Device for Fitting Molds: ● This machine comes standard with a dual hydraulic core-pulling system, specifically engineered for complex pipe fitting molds. It ensures smooth internal surfaces and damage-free demolding, enabling stable and highly automated part ejection. This design significantly enhances the dimensional accuracy of pipe fittings and boosts production efficiency, meeting the core demands of high-quality PVC/CPVC fitting manufacturing. |

|

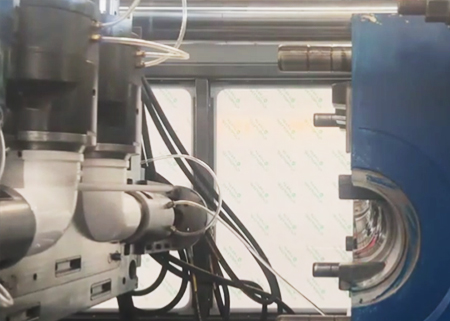

Barrel Air Fan Cooling & PID Temperature Control System: ● Addressing the thermal sensitivity of PVC/CPVC, key barrel zones feature high-efficiency forced air cooling. This system precisely assists heat dissipation, effectively preventing material overheating and decomposition. Integrated with a high-precision PID closed-loop temperature control system, it ensures stable and uniform temperature profiles throughout the barrel, providing the ideal thermal environment for material plastication and guaranteeing consistent product quality. |

|

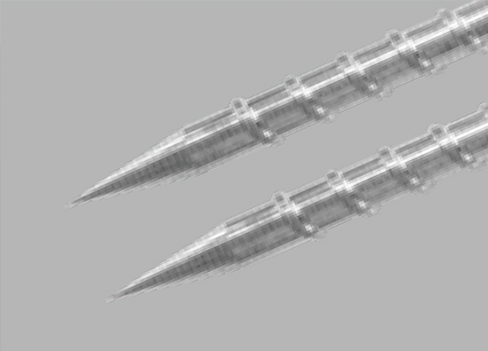

Dedicated Screw and Barrel for PVC/CPVC: ● The core plasticating unit utilizes a screw and barrel specifically optimized for PVC/CPVC material characteristics. Key features like optimized L/D ratio, compression ratio, and flight design ensure efficient and uniform plastication under gentle shearing forces. This minimizes thermal stress and degradation risks while simultaneously enhancing plasticizing capacity and melt quality, contributing to extended equipment lifespan. |

|

Enlarged Feeding System with High-Torque Motor: ● Equipped with a larger-capacity hopper and an optimized feed throat design, this system effectively prevents bridging or feeding interruptions common with PVC/CPVC powders or pellets. The drive system incorporates a high-torque motor, delivering ample power to ensure stable screw rotation even under high backpressure conditions. This robust setup enables powerful conveyance and thorough plastication of high-viscosity PVC/CPVC melts, markedly improving plasticizing efficiency and stability. |

|

Widened Safety Doors Compatible with Core-Pulling Cylinder Structures: ● The machine's safety doors are specifically widened to fully accommodate the spatial requirements of the large core-pulling cylinders typical in pipe fitting molds. While maintaining strict safety compliance, this design provides greater accessibility for easier mold installation, setup, and maintenance tasks, optimizing workflow and enhancing synergy between the machine and mold. |

|

Intelligent Control Unit with User-Friendly Interface & Rapid Response: ● Featuring an advanced intelligent control system coupled with a high-resolution, intuitive Human-Machine Interface (HMI). The system offers powerful data processing capabilities and rapid response times for convenient parameter setting and monitoring. It supports process recipe storage and recall, providing real-time machine status and diagnostic information, which significantly simplifies operations and boosts production management efficiency and process control. |

How PVC Injection Molding Machines Enhance Production Efficiency PVC injection molding machines can significantly enhance production efficiency by streamlining manufacturing processes, improving prod...

READ MOREThe direct answer is yes: the HXM Servo Injection Molding Machine is designed to deliver high precision, lower energy consumption, and stable production performance, making it ideal for manufacturers ...

READ MOREThe HXYD hybrid injection molding machine represents a significant evolution in manufacturing technology. Combining the strengths of electric and hydraulic systems, it provides an efficient and flexib...

READ MOREA Two Color Injection Molding Machine is an advanced manufacturing system designed to produce plastic parts using two different materials or two different colors in a single molding cycle. This techno...

READ MOREWith the continuous development of industry, intelligent manufacturing and energy conservation and environmental protection have become important trends in the manufacturing industry. Especially in th...

READ MORE1. What is a PVC Injection Molding Machine?

A PVC injection molding machine is a type of injection molding equipment specifically designed for processing polyvinyl chloride (PVC) plastic products. PVC material is heat-sensitive and easily decomposes during heating, therefore requiring higher demands on the injection molding machine's screw structure, temperature control accuracy, injection system, and venting capabilities. By optimizing the plasticizing system and corrosion-resistant components, PVC injection molding machines can stably and efficiently produce PVC products such as pipes, fittings, electrical accessories, valves, and daily necessities housings.

Ningbo Beilun Highsun Machinery Co., Ltd. is a professional China PVC Injection Molding Machine Manufacturers and PVC Injection Molding Machine Factory, We specialise in producing and marketing high-grade precision plastic injection molding machines under the "HIGHSUN" brand.

2. Advantages and Features of PVC Injection Molding Machines

The main advantages of PVC injection molding machines lie in their plasticizing stability and corrosion resistance. The specialized screw reduces decomposition and improves product purity. The precise temperature control system ensures that the material is molded at the appropriate processing temperature, preventing product yellowing, scorching, or brittleness. The injection system provides stable pressure output, resulting in uniform wall thickness and high dimensional consistency of PVC products. The equipment has low energy consumption and high efficiency, meeting the needs of large-scale, long-term industrial production. The robust structural configuration also reduces downtime and maintenance requirements.

PVC injection molding machines utilize a specialized PVC wear-resistant and corrosion-resistant screw and barrel design, effectively reducing material decomposition and black spot formation. The equipment is equipped with a precise temperature control system to stabilize the temperature in the heating zone, preventing PVC degradation due to uneven heating. The clamping mechanism has a high-rigidity structure, suitable for long-term, high-pressure injection molding operations. Some models are equipped with a venting system and increased back pressure capabilities for more uniform plasticization. The overall machine structure emphasizes stability, durability, and safety, adapting to the special processing requirements of PVC materials.

3. Typical Application Areas

PVC injection molding machines are widely used in pipe and fitting manufacturing, building materials, electrical accessories, valves, daily necessities, home improvement accessories, automotive air conditioning components, and some PVC products in the medical industry. For example: PVC elbows, tees, connectors, flanges, electrical conduit fittings, valve housings, electrical boxes, battery holders, etc. Due to the wide variety and high demand for PVC products, PVC injection molding equipment has a huge market in the building materials and consumer goods sectors.

4. Operation and Maintenance Key Points

The operation of PVC injection molding machines is quite strict, requiring precise control of the temperature in each section to prevent material decomposition due to overheating. Operators should master the material heating curve, injection speed, and back pressure adjustment techniques. In terms of maintenance, ensure that the screw is cleaned regularly to prevent PVC residue carbonization; check that the heating elements, temperature sensors, and cooling system are functioning correctly; maintain unobstructed mold venting; and regularly change the hydraulic fluid in the hydraulic system. Due to the corrosive nature of PVC, all contact parts should be regularly inspected for wear.

PVC Injection Molding Machine Maintenance Precautions Table:

| Maintenance Area | Key Tasks | Frequency | PVC-Specific Notes |

| Daily Checks | |||

| Material Corrosion | Inspect screw, barrel, and nozzles for acid corrosion | Each shift | PVC decomposition produces HCl - check for pitting |

| Ventilation | Verify fume extraction system operation | Daily | Critical for chlorine gas removal |

| Weekly Maintenance | |||

| Screw/Barrel Cleaning | Purge with PE or PP-based cleaning compound | Weekly | Never use ABS or PS for cleaning |

| Temperature Zones | Calibrate all heaters (max 190掳C for PVC) | Weekly | Overheating causes degradation |

| Monthly Tasks | |||

| Hydraulic System | Check oil for acidity (pH<6 requires change) | Monthly | Use corrosion-resistant hydraulic oil |

| Mold Maintenance | Deep clean venting channels and corrosion spots | Monthly | Chrome-plated molds recommended |

| Quarterly Procedures | |||

| Electrical Components | Inspect for chloride deposits on contacts | Quarterly | Use dielectric grease for protection |

| Safety Systems | Test emergency ventilation activation | Quarterly | Must activate within 3 seconds of alarm |

| Annual Maintenance | |||

| Corrosion Protection | Reapply anti-corrosion coatings to exposed metal | Annually | Focus on platen and clamp areas |

| Exhaust System | Replace HEPA and acid gas filters | Annually | Required even if appearing clean |

5. FAQ: Common Questions about PVC Injection Molding Machines

Q1: Can a standard screw be used in a PVC injection molding machine?

A1: It is not recommended. Standard screws lack sufficient corrosion and wear resistance, leading to problems such as decomposition, black spots, and poor plasticization, affecting product quality.

Q2: What should I do if scorching occurs during PVC injection molding?

A2: Check if the temperature control system is overheating, if there is insufficient venting, if the back pressure is too high, and the condition of the screw wear.

Q3: Can it produce both rigid and flexible PVC?

A3: Yes, both rigid and flexible PVC are supported, but the process parameters need to be adjusted separately.

Q4: Is the PVC injection molding machine energy-efficient?

A4: Most modern PVC injection molding machines use servo energy-saving systems, which can save 30%-60% energy compared to traditional machines.

Q5: Does the equipment require special cleaning?

A5: Yes. PVC residue is prone to degradation, so it is essential to use a special cleaning agent or PE to clean the machine before shutting down to prevent carbonization problems.