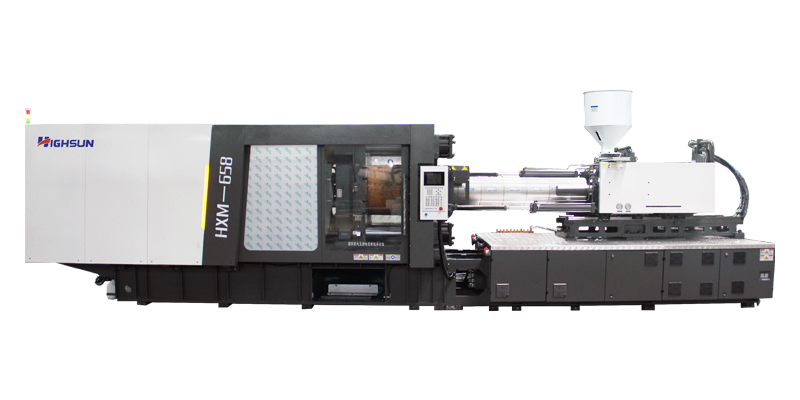

HX-HIGHSUN is one of the professional Plastic Injection

Molding Machine manufacturers with 45years plus of experience.

Strong Production Capacity

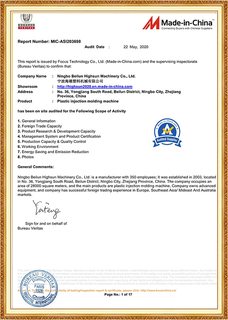

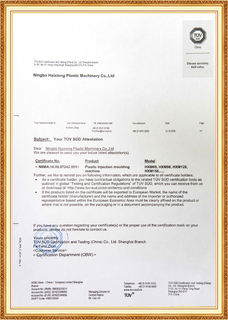

As one of the top 5 plastic injection molding machine factories in China issued by China Machinery Industry Federation (CMIF). We produce 7000sets machines per year. HX-HIGHSUN has the world advanced hardware like 1million square feet of modern plant; equipped with advanced CNC machining and processing system(CNC utilization ratio: above 83%) . Achieve mass production and part of flow-line running.

Realized more than 100million US$ sales in 2018, constantly 5years was awarded “top 3” of comprehensive strength & development potential for IMM manufacturer by CPIMMA.

We produce and supply various of products, HXM(servo energy saving series, 98ton-3500ton)、HXF (double proportion fixed pump series:98ton-730ton)、HXW(variable pump energy saving series:98ton-730ton)、HXH(high-speed series: 160ton-520ton)、HXYD(hybrid high-performance series: 160ton-700ton)、SP(smart power series:100ton-300ton)、HXS(two color series, unmixed & mixed) and special PET series, PVC series, Bakelite series, etc.

Especially we always research and supply individual solutions according to customer’s demands, we make special customization included upgraded power system & hydraulic system and special design of screw & barrel to meet requirements like quicker cycle time and higher production efficiency. Successfully developed More professional solutions with high-performance for Painting Bucket, Chair and Crate,etc. are developed successfully.

To make a mark and boost the visibility of the HIGHSUN brand in overseas markets, we consistently adhere to the marketing conception of “Customer First, Service Fast”, concentrate on developing and expanding sales & service center. Till now, we have successfully established service center in:

South-Korea, Malaysia, Thailand, Indonesia, Uzbekistan, Bangladesh.

Turkey, Poland, Italy

South Africa, Nigeria, Ethiopia, Algeria, Tunis, Egypt

Mexico, Colombia, Ecuador, Argentina to extend and guarantee pre-sale, sale, after-sale service in overseas markets.

English

English Español

Español عربى

عربى русский

русский