Content

What factors influence injection molding costs?

Material Cost

Raw Material Price: Fluctuations in the price of plastic pellets (such as ABS, PP, and PC) directly impact costs, typically accounting for 50% to 70% of the total injection molding cost.

Material Utilization: High scrap rates (e.g., runners, gates, and defective parts) increase material consumption. Design optimization (e.g., reducing wall thickness) or recycling scrap can reduce costs.

Additives and Masterbatch: Special requirements (e.g., flame retardancy and UV resistance) increase material costs.

Mold-Related Costs

Mold Design and Complexity: Complex structures (e.g., sliders, beveled lifters, and precision textures) increase mold manufacturing costs and maintenance difficulties.

Mold Life: Steel grade (e.g., P20, H13) and surface treatment (chrome plating, nitriding) affect mold life and replacement frequency.

Number of Cavities: Multi-cavity molds can increase single-shot production, but the initial investment is higher, so a balance must be struck between production capacity and demand.

Process Parameters and Efficiency

Cycle Time: Shortening cooling time and optimizing holding pressure parameters can improve efficiency, but avoid defects (such as sink marks) caused by excessive cooling.

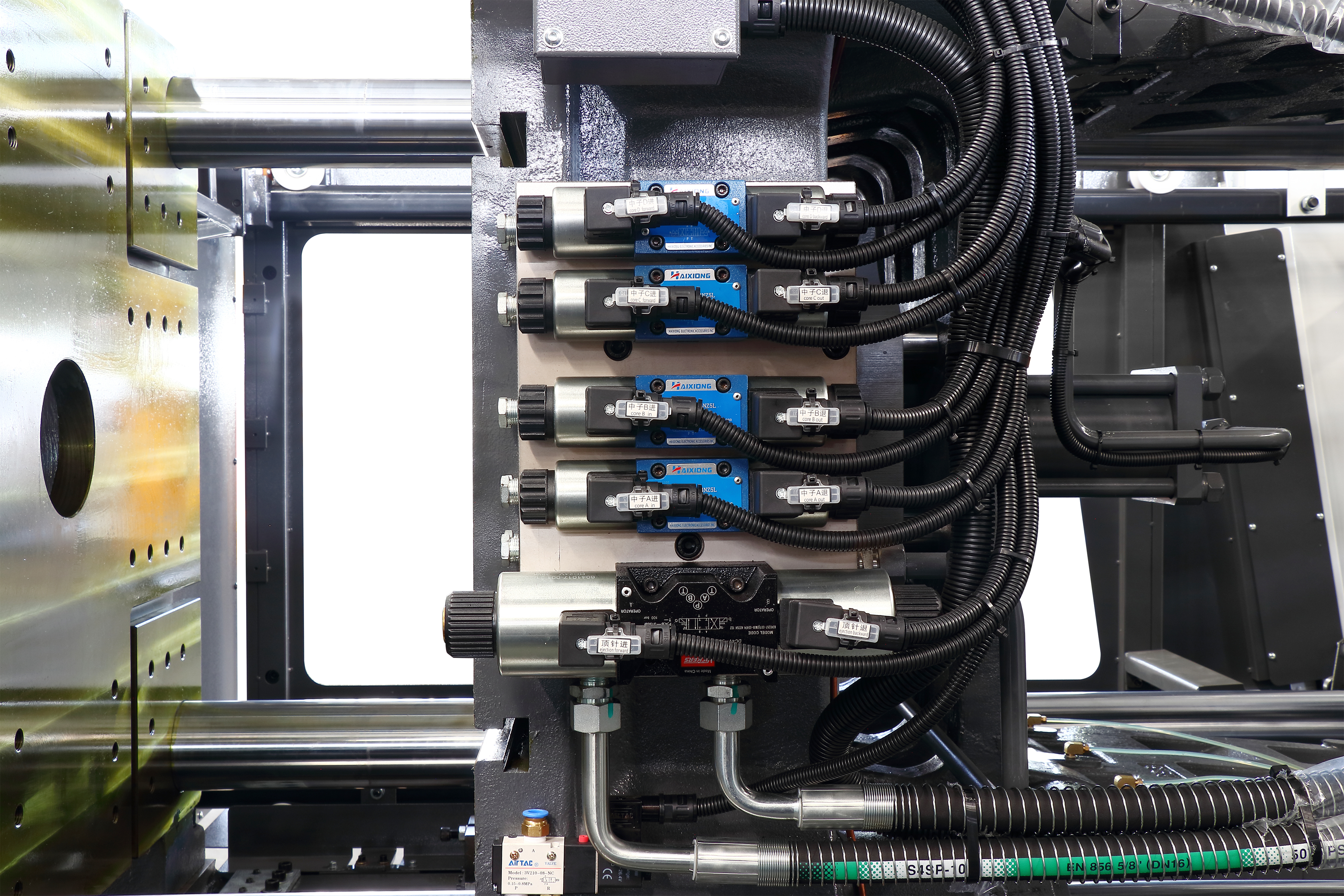

Energy Consumption: Significant differences exist in the tonnage of the injection molding machine, hydraulic vs. electric models (electric models are energy-efficient but costly), and the energy consumption of the heating/cooling system.

Yield: Process instability (such as temperature and pressure fluctuations) can lead to problems such as flash and short shots, increasing scrap costs.

Equipment and Labor

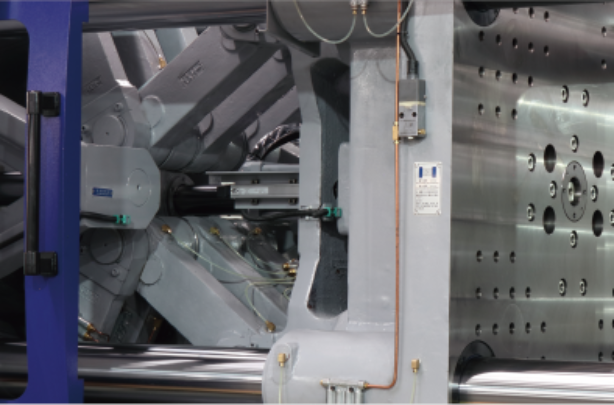

Equipment Selection: High-precision injection molding machines are suitable for precision parts but are expensive; used equipment can reduce investment but may increase maintenance costs.

Labor Cost: Automation (robots, automatic part removal) reduces reliance on labor, but initial investment must be considered.

Maintenance and Depreciation: Regular equipment maintenance can reduce downtime and extend service life.

Product Design Optimization

Wall Thickness Uniformity: Uneven wall thickness can lead to uneven cooling, extending cycle time and increasing scrap.

Draft Angle and Structure: Improper design can make demolding difficult or require additional post-processing (such as polishing). Standardization: Reducing the number of part types and specialized structures can reduce mold and production complexity.

Batch Size and Logistics

Order Size: Large-volume production spreads out mold and commissioning costs, while small batches result in higher unit costs.

Packaging and Shipping: Product fragility may require specialized packaging, increasing logistics costs.

Management and External Factors

Supply Chain Stability: Raw material delays or price increases can drive up costs.

Environmental Compliance: Waste disposal (e.g., VOC emissions, recycling certification) can incur additional costs.

Geography: Energy prices, labor costs, and tax policies vary significantly across factory locations.

Main Cost Components of Two-Color Injection Molding

- Equipment Cost

High Machine Price: Two-color injection molding machines are typically 1.5 to 3 times more expensive than standard injection molding machines.

Higher Energy Consumption: Requires two injection systems, resulting in 20% to 40% higher energy consumption than single-color machines.

- Mold Cost

High Mold Complexity: Two-color molds have two sets of cavities, requiring precise alignment and increased processing complexity. Costs are 2 to 4 times higher than standard molds.

High Maintenance Cost: Due to the complex structure, repair and maintenance costs are higher.

- Material Cost

Mixed Materials: Requires purchasing two different plastics (e.g., hard plastic + soft plastic), which may involve special materials (e.g., TPE, PC/ABS).

Material Compatibility Requirements: The two materials must adhere well, otherwise additional processing (e.g., adding adhesive) is required.

- Process Cost

Long Debugging Cycle: Two-color injection molding requires more complex parameter adjustments (e.g., matching temperature and injection time), resulting in a higher scrap rate during debugging. Yield Challenges: Large differences in shrinkage between two materials can easily lead to delamination and warping, increasing scrap costs.

- Labor and Management Costs

High Operational Requirements: Requires skilled technicians for commissioning and maintenance, resulting in higher labor costs.

Complex Production Scheduling: More frequent color and material changes impact efficiency.

How to reduce the cost of injection molding in production?

Optimize material costs

(1) Select suitable plastic materials

Evaluate performance requirements: Select lower-priced materials while meeting product performance (such as strength, heat resistance, and appearance).

Use recycled materials: Add a certain proportion of recycled materials (such as crushed runners and waste products) without affecting quality.

Reduce additives: Avoid excessive use of expensive additives such as masterbatches and flame retardants.

(2) Improve material utilization

Optimize the pouring system: Use hot runner molds to reduce cold runner waste.

Reduce wall thickness: Reduce product wall thickness and material usage while ensuring strength.

Recycling: Collect runners and waste products during the injection molding process, crush them and reuse them (it is necessary to evaluate whether the material performance is affected).

Optimize mold design and management

(1) Improve mold efficiency

Multi-cavity design: Increase the number of mold cavities to increase single-shot output.

Optimize the cooling system: Use conformal cooling or high-efficiency water channel design to shorten cooling time. Simplify the structure: reduce the complex mechanisms such as sliders and lifters, and reduce the cost of mold manufacturing and maintenance. (2) Extend the life of the mold Select high-quality steel (such as H13, S136) and perform surface treatment (chrome plating, nitriding) to reduce wear. Regular maintenance: clean the mold cavity and check the guide pins/elevator to avoid downtime or scrap due to mold damage.

Optimize the injection molding process

(1) Shorten the production cycle Reduce the cooling time: optimize the cooling water path layout or use rapid cooling technology (such as beryllium copper inserts). Adjust the holding pressure parameters: avoid excessive holding pressure that leads to extended cycle or material waste. High-speed injection molding: use high shooting speed to reduce filling time, but prevent flash or burning. (2) Improve the yield rate Process stability: find the optimal combination of temperature, pressure, and speed parameters through DOE (design of experiments).

Equipment optimization and automation

(1) Select the right injection molding machine

Tonnage molding machine

Tonnage matching: Avoid "a big horse pulling a small cart" and select a machine with the right clamping force to reduce energy consumption.

Energy-saving models: Give priority to all-electric or hybrid injection molding machines (30%~50% more energy-efficient than hydraulic presses).

(2) Reduce dependence on manual labor

Automated part removal: Use a robot to remove parts, reducing manual operation time and errors.

Centralized feeding system: Automatically transport raw materials, reducing manual feeding and mixing errors.

Production management optimization

(1) Batch production and scheduling

Reduce the number of mold changes: Extend the production batch of the same product by merging orders.

Rationally arrange production plans: Avoid frequent switching of materials or molds, and reduce debugging waste.

(2) Supply chain management

Centralized procurement: Sign long-term agreements with suppliers to reduce raw material procurement costs.

Localized procurement: Reduce transportation and warehousing costs.

(3) Energy management

Peak power consumption: Arrange high-energy-consuming processes during periods of low electricity prices. Waste Heat Recovery: Utilize waste heat from injection molding machine cooling water for workshop heating or other purposes.

- Product Design Optimization

Simplified Structure: Reduce unnecessary complex features (such as undercuts and thin walls) to reduce mold and process complexity.

Standardized Design: Utilize universal structures whenever possible to reduce the need for specialized molds.

DFM (Design for Manufacturing): Consider injection molding feasibility during the design phase to avoid costly modifications later.

Strategies for Reducing Two-Color Injection Molding Costs

- Optimizing Equipment Selection

Choose a machine model based on demand:

If production volumes are low, consider a rotary two-color injection molding machine (lower cost than a parallel type).

For small product sizes, choose a small two-color machine to reduce energy consumption and material waste.

Used Equipment or Leasing: Initially, consider using used equipment or leasing to reduce investment pressure.

- Mold Design Optimization

Simplified Structure: Reduce complex mechanisms such as sliders and lifters to reduce processing difficulty.

In-Mold Rotation Design: Use a rotating core instead of a dual-cavity mold to reduce mold costs.

Standardized Mold Base: Use a universal mold base and customize only core components to reduce development costs.

- Material Cost Control

Prioritize Material Compatibility: Choose materials with similar shrinkage rates (e.g., PP + TPE) to reduce the risk of delamination.

Use Recycled Materials: Use recycled materials in areas where performance is not affected (e.g., internal structures).

Reducing Expensive Materials: For example, for exterior parts, use only high-gloss material for the outer layer and standard material for the inner layer.

- Process Optimization

Fine Parameter Adjustment: Use DOE experiments to identify the optimal combination of temperature, pressure, and cooling time.

Mold Temperature Control: Independently control two mold temperatures to ensure the quality of the material interface.

Automated Monitoring: Install sensors to monitor the injection molding process in real time to reduce human error.

- Production Management Improvement

Batch Production: Maximize the production cycle for the same product and reduce mold/material change time.

Preventive Maintenance: Regularly maintain molds and machines to avoid unexpected downtime.

Operator Training: Enhance technicians' understanding of the two-color process and reduce debugging waste.

- Product Design Cost Reduction

Reduce Two-Color Areas: Use two-color design only in essential areas (such as buttons and seals).

Structural Simplification: Avoid over-design, such as replacing part of the two-color structure with overmolding.

ENG

ENG  English

English русский

русский Español

Español Português

Português عربى

عربى

+86-188 6861 6288

+86-188 6861 6288 haixiong@highsun-machinery.com

haixiong@highsun-machinery.com No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China

No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China