HXM servo machine manufacturers

1. Super energy saving, output power varies with load , and no energy is wasted , in the holding pressure phase ,the servo motor will reduce speed with low energy consuption;during the cool down period , the motor does not work ,with zero power consumption ,compared with the ordinary injection molding machines , it can save 20% to 80% of the power .

2. High precision and high stability , Equipped with the precise pressure sensor and rotary encoder , it can respectively monitor and feed back on the flow and pressure .Based on the feedback ,the high performance synchronous servo motor will adjust flow and pressure accordingly by changing the speed and torque . The closed-loop control can ensure the stability of product quality .

3. High response and High efficiecy, the driving system responsed with high sensitivity . It take only 0.05 seconds to reach maximum value . The response speed is much faster than the ordinary injection molding machines , in the way, it significantly shortens the cycle time and increases the production efficiency .

4. Bigger tie bar distance ,compare with other supplier ,we have bigger tie bar distance ,we can put big molds in the machine

5. Long openging stroke , compare with other suppliers ,we have long opening stroke which can produce deep cavitiy product install competitor bigger size of machine .

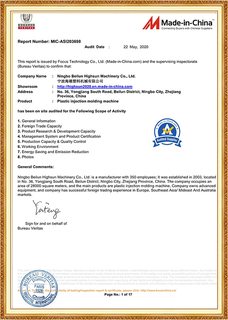

Ningbo Beilun Highsun Machinery Co., Ltd, established in 1973, is a leading

HXM servo machine manufacturers and

HXM servo machine Factory in China, with over 48 years of experience, Professional

HXM servo machine and other types of injection molding machines, equipped with advanced CNC machining system (CNC utilization rate: more than 83%). Achieve mass production and partial assembly line operation. As one of the top 5 plastic injection molding machine enterprises in China issued by China Machinery Industry Federation (CMIF). We produce 7,000 machines per year, and have the world's most advanced processing equipment and machining workshops. 90% of the mechanical components including the basic structure are produced in-house, which absolutely guarantees faster delivery; strict quality inspection system includes three Coordinate Measuring Machine (CMM) and MSA system to achieve closed-loop control of QA system, higher level of quality and service assurance.

English

English Español

Español عربى

عربى русский

русский