Choose Based on Product Requirements First — Not Machine Price The right PVC injection molding machine is the one that matches your product size, PVC formulation, and production volume. Clamping force...

READ MORE

|

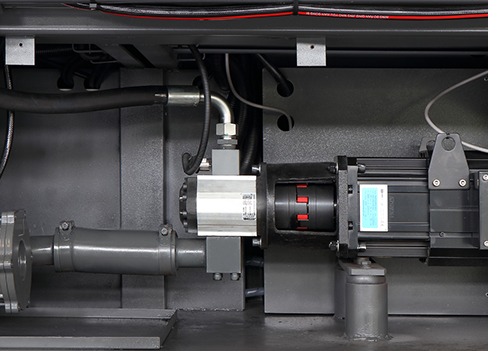

Enhanced Power & Hydraulic System ● Incorporates upscaled motors and pumps to establish a robust dynamic framework, with hydraulics precisely calibrated to PET injection requirements, ensuring stable and controllable pressure/flow parameters. |

|

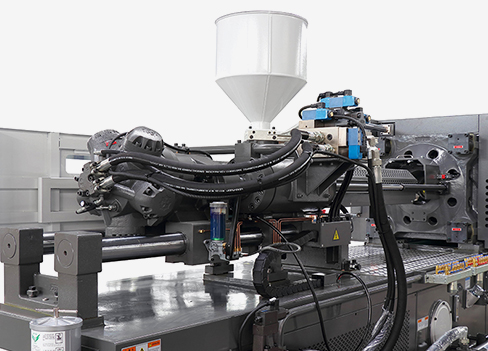

Specialized Screw Design ● Featuring increased L/D ratio (barrel length-to-diameter) and PET-optimized shearing elements that effectively reduce shrinkage deformation while enhancing the optical clarity of PET products. |

|

High-Torque Plasticization Motor ● Enhancing plasticization efficiency for more thorough and rapid PET material processing, driving high-efficiency production.

|

|

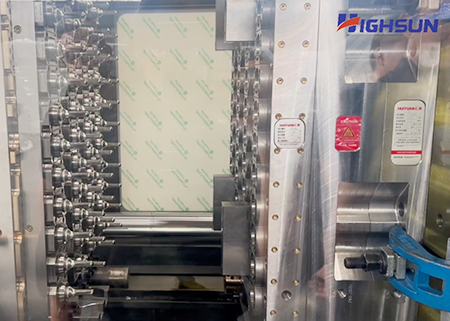

Dedicated Cooling Circuit & Ejection System ● Cooling Circuit: Accelerated mold cooling enables rapid PET product solidification, boosting cycle rates while enhancing dimensional stability (±0.05% tolerance). ● Ejection System: Augmented ejection force/stroke achieves streamlined demolding for multi-cavity PET products. |

Choose Based on Product Requirements First — Not Machine Price The right PVC injection molding machine is the one that matches your product size, PVC formulation, and production volume. Clamping force...

READ MORETroubleshooting Common Issues in PET Preform Injection Molding Machines PET preform injection molding machines are vital for producing high-quality plastic bottles and containers. However, like all m...

READ MOREHow PVC Injection Molding Machines Enhance Production Efficiency PVC injection molding machines can significantly enhance production efficiency by streamlining manufacturing processes, improving prod...

READ MOREThe direct answer is yes: the HXM Servo Injection Molding Machine is designed to deliver high precision, lower energy consumption, and stable production performance, making it ideal for manufacturers ...

READ MOREThe HXYD hybrid injection molding machine represents a significant evolution in manufacturing technology. Combining the strengths of electric and hydraulic systems, it provides an efficient and flexib...

READ MORE1. What is a PET Preform Injection Molding Machine?

A PET preform injection molding machine is a type of injection molding equipment specifically designed for producing PET preforms for beverage bottles, edible oil bottles, cosmetic bottles, medical packaging bottles, and other applications. PET material has high transparency, high strength, and good processing performance, but its high plasticization temperature and rapid crystallization rate require special requirements for the injection machine's plasticizing system, temperature control system, cooling capacity, and injection speed. By optimizing plasticization, cooling, and high-speed injection control, PET preform injection molding machines produce preforms with higher transparency and more uniform wall thickness, ensuring more stable subsequent blow molding.

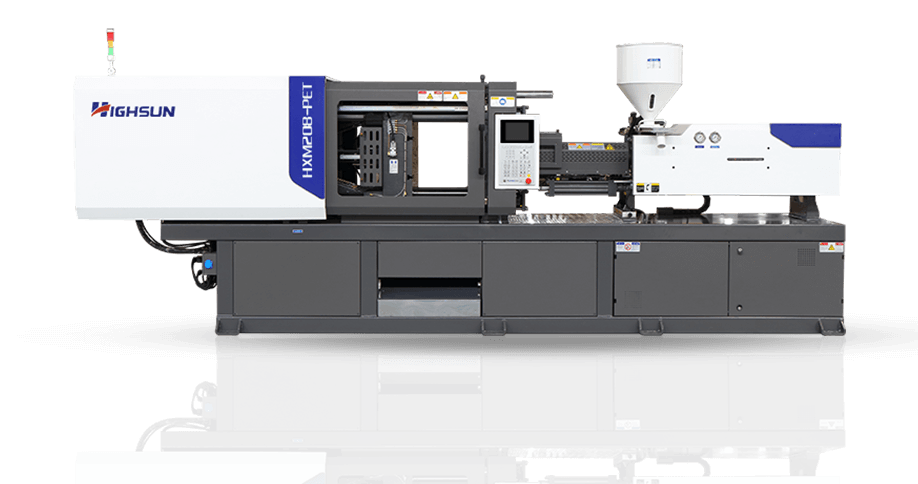

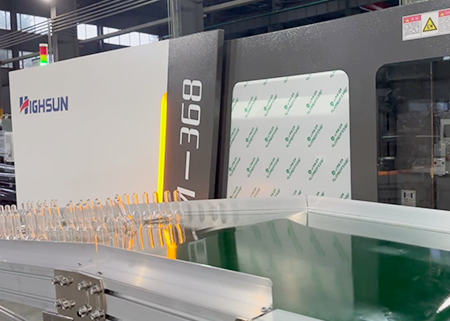

Ningbo Beilun Highsun Machinery Co., Ltd. is a professional China PET Preform Injection Molding Machine Manufacturers and PET Preform Injection Molding Machine Factory, We specialise in producing and marketing high-grade precision plastic injection molding machines under the "HIGHSUN" brand. has long been dedicated to delicacy management and zero defect production, and has formed a characteristic series represented by small tonnage of hybrid machine, medium tonnage of toggle machine, and large tonnage of two-platen machine.

2. Advantages of PET Preform Injection Molding Machines

The advantages of PET preform injection molding machines lie in their high efficiency, stability, and high-transparency molding capabilities. Their specialized screw structure improves plasticization efficiency, resulting in a more uniform melt and reducing black spots and poor crystallization. The high-speed injection system ensures uniform preform wall thickness, improving the consistency of subsequent blow molding. The efficient cooling system significantly reduces the molding cycle, leading to a significant increase in production capacity. The equipment has high energy efficiency; servo drives enable energy saving, low noise, and low energy consumption, making it suitable for long-term mass production.

3. Application Fields of PET Preform Injection Molding Machines

PET preform injection molding machines are mainly used in the packaging industry, especially for beverage and food packaging. Examples include preforms for mineral water bottles, carbonated beverage bottles, juice bottles, condiment bottles, cosmetic bottles, and medical bottles. Due to the huge demand for PET preforms, the equipment is often used in continuous high-speed production lines in medium and large factories, and can be linked with automatic feeding systems, robotic arms, and blow molding machines to achieve automated production.

4. Operation and Maintenance Key Points

The key to operating a PET preform injection molding machine is controlling the plasticization temperature, injection speed, and cooling speed. Operators must strictly manage raw material drying (PET must be thoroughly dehumidified) to avoid moisture causing haze and silver streaks. For maintenance, regular checks should be performed on screw wear, the stability of the barrel temperature control zone, leaks in the high-pressure oil circuit, and the unobstructed flow of the mold cooling water circuit; the filter should be kept clean and the dryer should be kept working stably. Because PET material is easily affected by moisture, the drying system before production is especially important.

PET Preform Injection Molding Machine Maintenance Guide:

| Maintenance Area | Key Tasks | Frequency | PET-Specific Notes |

| Daily Checks | |||

| Drying System | Verify dryer temperature (150-180°F) and dew point (-40°F) | Each shift | Moisture >0.02% causes hydrolysis |

| Crystallization | Check preform neck finish crystallization uniformity | Every run | Use IR thermometer (target 125-140°C) |

| Weekly Maintenance | |||

| Screw/Barrel | Inspect for wear (L/D≥20:1 recommended) | Weekly | Hardened surfaces required (HRC≥60) |

| Hot Runner System | Clean nozzles and check thermal sensors | Weekly | Maintain ±1°C accuracy for color consistency |

| Monthly Tasks | |||

| Cooling Channels | Descale with citric acid solution (10%) | Monthly | Calcium buildup reduces cooling efficiency |

| Hydraulic System | Check oil temperature (max 45°C) and filter condition | Monthly | PET requires stable pressure (±2% tolerance) |

| Quarterly Procedures | |||

| Clamping Unit | Verify platen parallelism (≤0.02mm/m²) | Quarterly | Critical for uniform wall thickness |

| IV Preservation | Test intrinsic viscosity drop (ΔIV≤0.02 dl/g) | Quarterly | Indicates thermal degradation |

5. FAQ: Common Questions about PET Preform Injection Molding Machines

Q1: Why do PET preforms require a dedicated injection molding machine?

A1: PET requires high plasticizing temperature, high injection speed, and excellent cooling capacity. Ordinary injection molding machines cannot meet the requirements for stable production.

Q2: Why must PET raw materials be pre-dried?

A2: PET is highly hygroscopic. Insufficient drying can lead to quality problems such as silver streaks, bubbles, and haze in the preforms.

Q3: What is the typical injection molding cycle time for PET preforms?

A3: Depending on the number of cavities, mold cooling design, and machine tonnage, it generally ranges from 6 to 20 seconds per mold. High-speed machines can be even faster.

Q4: What should I do if the preform wall thickness is uneven?

A4: You need to check the injection speed curve, mold cooling uniformity, raw material dryness, and screw plasticizing capacity.

Q5: Can the PET preform injection molding machine be connected to a blow molding machine?

A5: Yes, most factories use an automated preform injection molding and blow molding production line, which can significantly improve efficiency and stability.