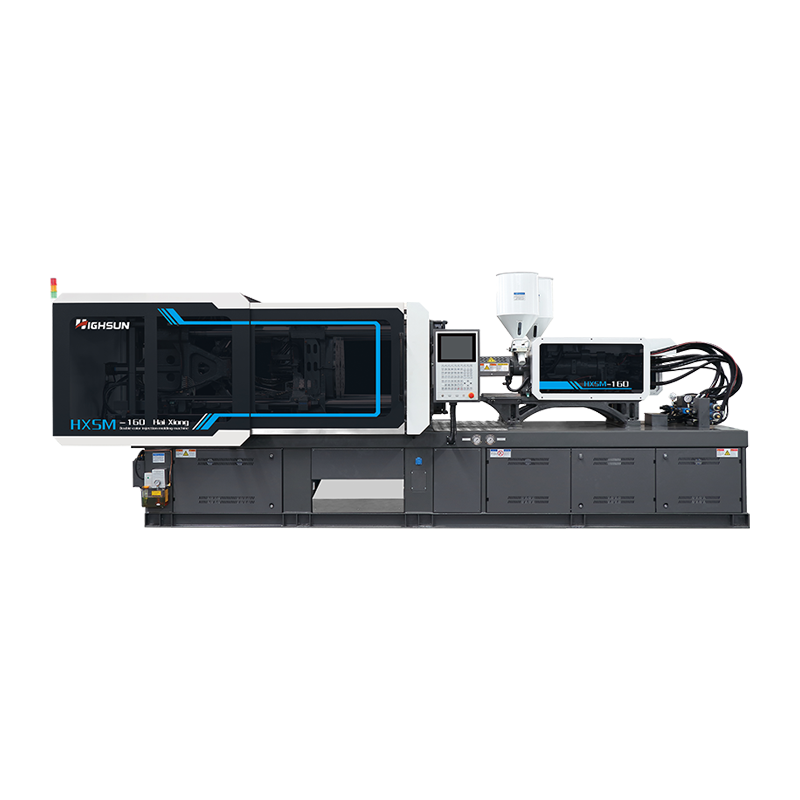

HXS Two-Color Machine

HXS160: HXS two-color injection molding machine

Designed specifically for the molding of dual-color or multi-color plastic products. Its core function enables the integration of two different colors or materials of plastic within a single product through two independent injection units (or a rotating mold structure). Widely applied in automotive components, 3C electronics, home appliances, medical equipment, and other fields, it features high-efficiency production, energy conservation, and environmental sustainability.

ENG

ENG  English

English русский

русский Español

Español Português

Português عربى

عربى

+86-188 6861 6288

+86-188 6861 6288 haixiong@highsun-machinery.com

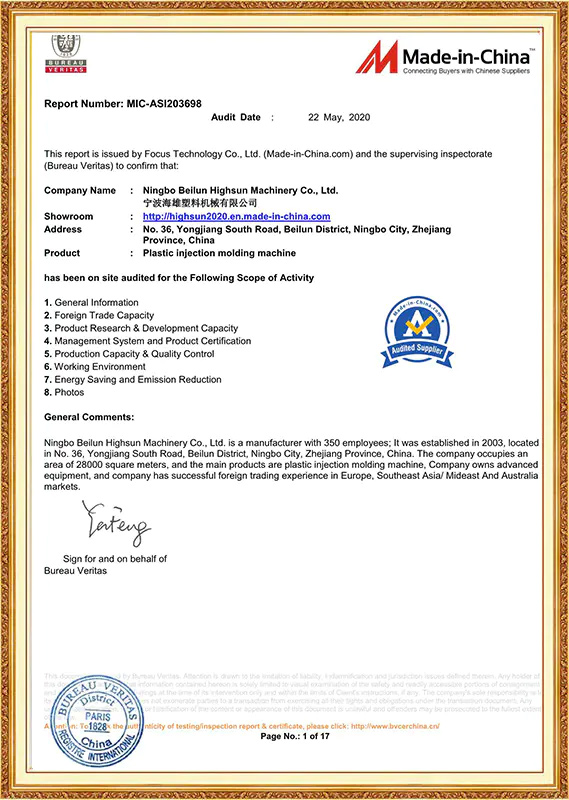

haixiong@highsun-machinery.com No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China

No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China