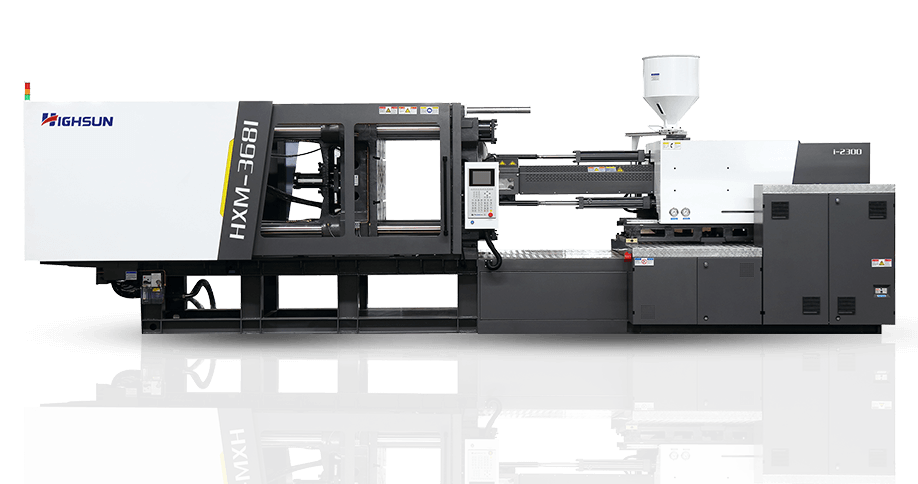

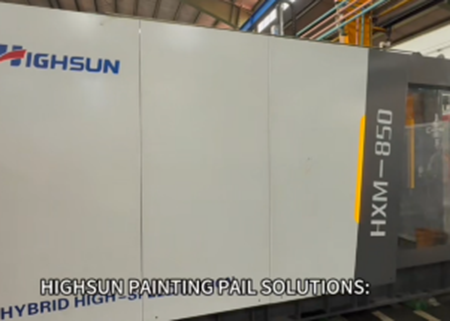

The direct answer is yes: the HXM Servo Injection Molding Machine is designed to deliver high precision, lower energy consumption, and stable production performance, making it ideal for manufacturers ...

READ MORE

|

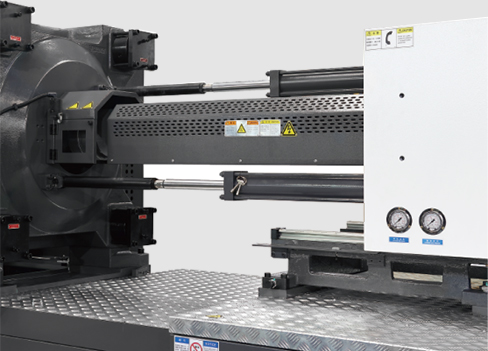

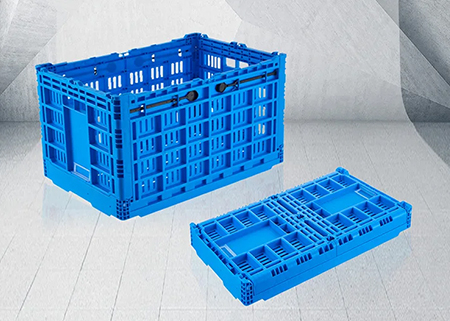

INJECTION UNIT ● A special, structured, hard alloy screw barrel has been developed for complex fruit basket raw materials, greatly improving the speed and service life of the melt adhesive |

|

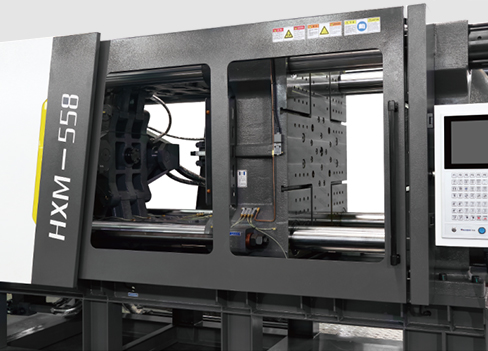

CLAMPING UNIT ● Adopting the design concept of high-speed machines, the rigidity and strength of the locking mold, shooting platform, and body have been optimized and strengthened, making the machine operate more stably and have a longer lifespan. |

|

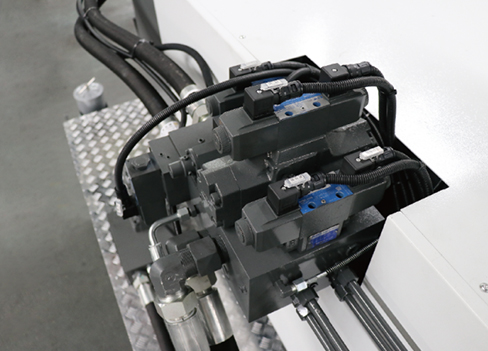

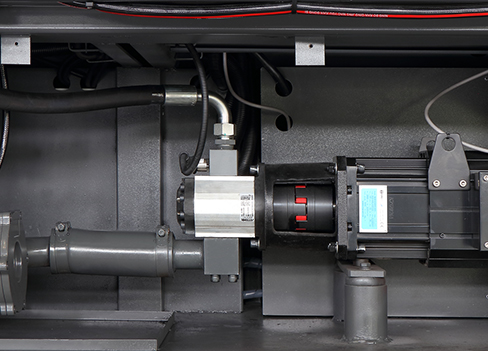

HYDRAULIC UNIT ● Equipped with a dedicated melt adhesive motor to ensure high lifespan under high-speed working conditions. |

|

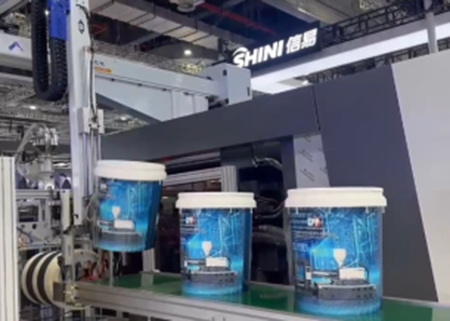

INJECTION UNIT ● Upgraded the power system to provide strong power to the entire machine, greatly improving its operating speed and shortening the production cycle. |

The direct answer is yes: the HXM Servo Injection Molding Machine is designed to deliver high precision, lower energy consumption, and stable production performance, making it ideal for manufacturers ...

READ MOREThe HXYD hybrid injection molding machine represents a significant evolution in manufacturing technology. Combining the strengths of electric and hydraulic systems, it provides an efficient and flexib...

READ MOREA Two Color Injection Molding Machine is an advanced manufacturing system designed to produce plastic parts using two different materials or two different colors in a single molding cycle. This techno...

READ MOREWith the continuous development of industry, intelligent manufacturing and energy conservation and environmental protection have become important trends in the manufacturing industry. Especially in th...

READ MOREA two-color injection molding machine is an advanced plastic molding equipment that can inject two colors or two materials simultaneously. It is widely used in electronic products, household goods, au...

READ MORE1. What are heavy-duty crate molding presses?

Heavy-duty crate molding presses are a type of high-strength forming equipment used for processing large metal crates, cabinet housings, power equipment enclosures, machine frames, and other products. They primarily use hydraulic, servo, electric, or combined drive systems to bend, press, roll, stretch, or weld thick metal plates, achieving single or multiple forming of the crate structure. Due to the large size, thick materials, and high requirements of large crates, heavy-duty crate molding presses emphasize high rigidity, high pressure, stability, and precise control in their design, making them indispensable core equipment in large-scale manufacturing.

We are a professional China Optimization Crate Mold Injection Machine Manufacturers and Optimization Paint Bucket Mold Injection Machine Factory, We specialise in producing and marketing high-grade precision plastic injection molding machines under the "HIGHSUN" brand.

2. Equipment Structure Features

Heavy-duty crate molding presses generally adopt a heavy-duty steel structure frame and a high-strength guide rail system to ensure minimal deformation even under high tonnage pressure. The drive system is mostly servo-hydraulic or servo-electric, enabling stable, controllable, and low-noise processing. The forming area uses a widened work platform and reinforced press head to accommodate various sizes of crate processing needs. Combined with CNC systems, automatic positioning systems, and laser measuring devices, accuracy and repeatability are improved. For welded or spliced crates, the equipment also integrates auxiliary fixtures and centering mechanisms to make processing smoother.

3. Main Advantages of Heavy-Duty Crate Molding Presses

The core advantages of heavy-duty crate molding presses lie in their high strength, high precision, and high efficiency. The equipment can form thick plate materials in a single process, reducing repetitive processing and increasing production speed. The servo control system ensures smooth movement and accurate positioning, guaranteeing consistent geometric dimensions of the crates. Their energy consumption is lower than traditional hydraulic equipment, resulting in significant energy savings. The highly stable structure ensures that the equipment maintains accuracy over long-term operation, requiring less maintenance. Furthermore, the equipment has strong compatibility and can adapt to the crate processing needs of different industries, such as power distribution cabinet enclosures, power transformer housings, mechanical equipment cabinets, and transportation container crates.

4. Operation and Maintenance Essentials

Operating heavy-duty crate molding presses is relatively simple, but it requires adherence to standard procedures. Operators need to set parameters according to the process requirements and ensure correct fixture positioning. Before processing, the oil circuit, electrical control system, and safety light curtain should be checked for proper operation. Routine maintenance includes replacing hydraulic oil, regularly cleaning the guide rails, calibrating the positioning device, checking bolt tightness, and keeping the control system clean and dry. Good maintenance can significantly extend equipment life and ensure processing accuracy and stability.

| Maintenance Item | Procedure | Frequency | Precautions |

| Visual Inspection | Check for structural damage, loose bolts, hydraulic leaks, or worn parts. | Daily/Weekly | Tag and repair defects immediately to avoid safety risks. |

| Hydraulic System | Inspect oil levels, hoses, and seals; replace filters and check for leaks. | Weekly/Monthly | Use recommended hydraulic oil; depressurize before servicing. |

| Lubrication | Grease guide rails, bearings, chains, and other moving parts. | Daily/Weekly | Follow the lubrication chart; avoid over-greasing. |

| Pneumatic System | Check air pressure, filter regulators, and cylinder seals for wear. | Weekly | Drain moisture from air tanks; replace damaged tubing. |

| Electrical Components | Inspect wiring, connectors, and control panels for damage or overheating. | Monthly | Power off and lock out before inspection. |

| Clamping & Forming Tools | Verify alignment, sharpness, and wear of dies/molds. | Daily | Replace worn tools to maintain forming accuracy. |

| Belt & Chain Tension | Adjust tension and check for wear or misalignment. | Monthly | Follow manufacturer’s tension specifications. |

| Safety Devices | Test emergency stops, light curtains, and guards for proper function. | Weekly | Never bypass safety mechanisms. |

| Drive System | Inspect motors, gearboxes, and couplings for noise/vibration. | Monthly | Listen for unusual sounds indicating wear. |

| Software & Sensors | Calibrate sensors and update machine control software if needed. | Annually | Backup parameters before updates. |

| Debris Removal | Clean chips, dust, and debris from the machine bed and moving parts. | Daily | Use compressed air or brushes; avoid damaging components. |

| Professional Inspection | Schedule comprehensive checks (e.g., spindle wear, frame alignment). | Every 6-12 months | Use OEM technicians for critical components. |

5. FAQ: Common Questions about Heavy-Duty Box Forming Machines

Q1: What is the maximum thickness of sheet metal the equipment can process?

A1: It can usually process steel plates from 6mm to 20mm thick, or even thicker. The specific capacity depends on the equipment tonnage and structure.

Q2: Does the forming machine support processing boxes of different sizes?

A2: Yes. The workbench size, fixture structure, and stroke can be customized according to requirements to accommodate various box specifications.

Q3: Is it difficult to operate?

A3: No. Modern forming machines are mostly equipped with CNC systems, supporting graphical interfaces, parameter presets, and automatic forming.

Q4: Is the equipment energy-efficient?

A4: Servo hydraulic or servo electric systems have low energy consumption, saving 30%–60% compared to traditional hydraulic presses.

Q5: How often does it need maintenance?

A5: Daily cleaning can be performed every day, and key components such as hydraulic oil should be checked or replaced every 6–12 months depending on usage.