HXM Optimization For Crate / Painting Bucket

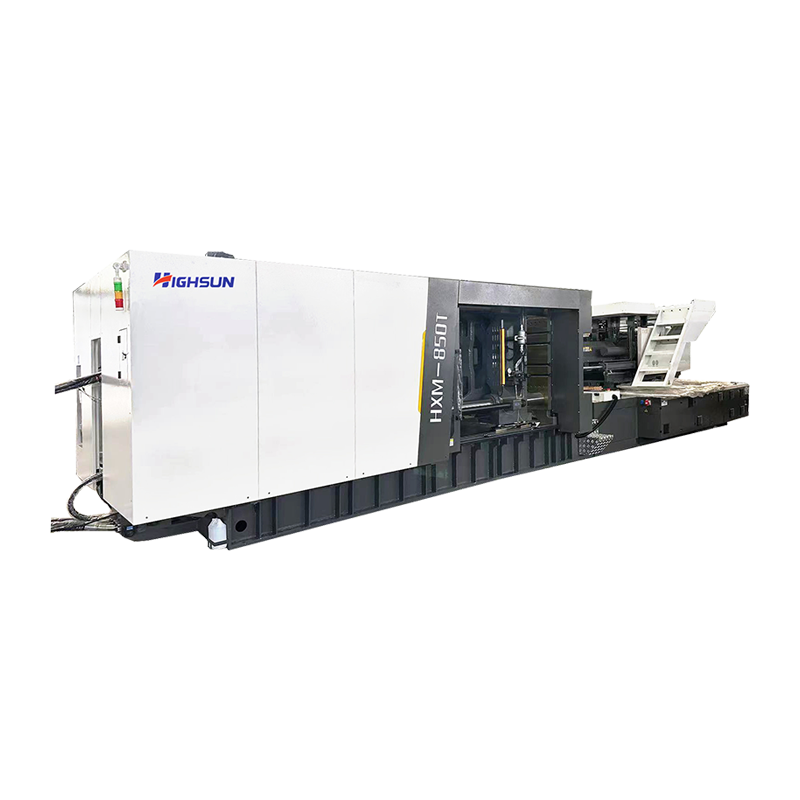

HXM850-T: HXM optimized edition for painting bucket

The Model 850T injection molding machine undergoes specialized optimization to meet the high demands of IML (In-Mold Labeling) film application processes for precision and coordination: it features a high-precision servo synchronous control system that accurately synchronizes with the film feeding rhythm of IML robots, ensuring a film positioning error of ≤0.1mm and preventing issues such as film misalignment and air bubbles. The clamping system adopts a reinforced five-point double-toggle structure, delivering a stable 850kN clamping force that securely holds the mold during the film-injection process, eliminating film wrinkling caused by unstable clamping. Additionally, the machine comes with dedicated IML interfaces, allowing direct integration with mainstream IML robotic arms and film feeding systems without requiring additional modifications, enabling quick setup of an integrated production line.

ENG

ENG  English

English русский

русский Español

Español Português

Português عربى

عربى

+86-188 6861 6288

+86-188 6861 6288 haixiong@highsun-machinery.com

haixiong@highsun-machinery.com No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China

No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China