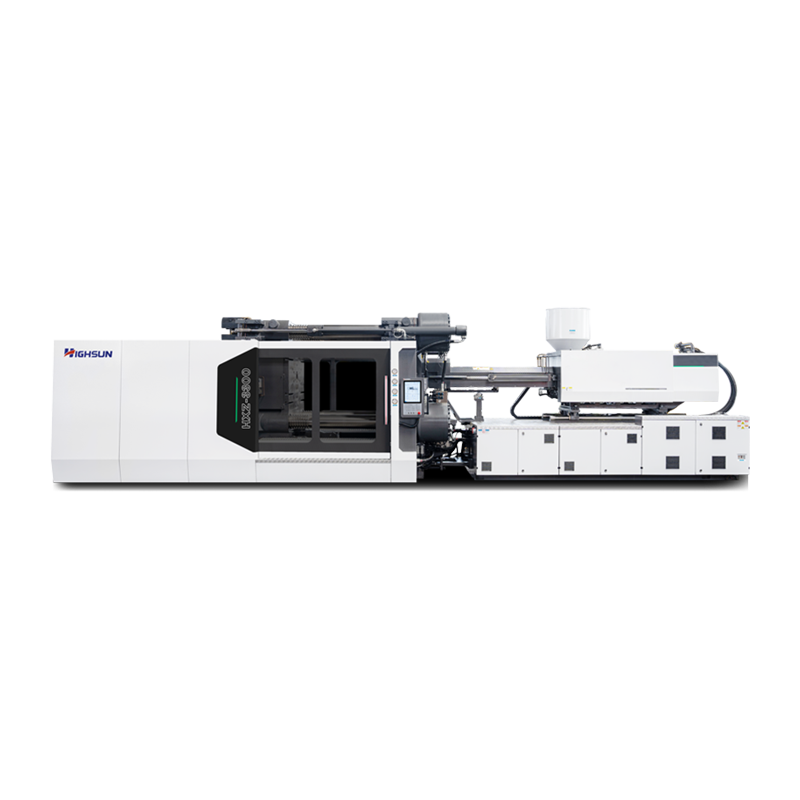

HXZ The Powerful Two-platen Injection Molding Machine

HXZ3300: two plate injection molding machinery series

The equipment is equipped with a cutting - edge servo - drive system. This system utilizes advanced sensors to capture the actual demands of each stage of the injection-molding process in real-time. It then employs sophisticated intelligent algorithms to respond rapidly and precisely regulate the rotational speed of the oil-pump motor. During the rapid-filling stage at the beginning of injection molding, the motor runs at a high speed, providing abundant pressure and flow with powerful force to ensure that the molten plastic can quickly and evenly fill the mold cavity within an extremely short time. When entering the holding-pressure stage, the motor automatically switches to the "energy-saving mode", smoothly reducing the rotational speed and maintaining a stable and appropriate pressure output. This not only guarantees the molding quality of plastic products but also avoids unnecessary energy consumption. Compared with traditional hydraulic systems, this precise control strategy has remarkable effects, capable of effectively reducing energy consumption by 30% - 70%.

ENG

ENG  English

English русский

русский Español

Español Português

Português عربى

عربى

+86-188 6861 6288

+86-188 6861 6288 haixiong@highsun-machinery.com

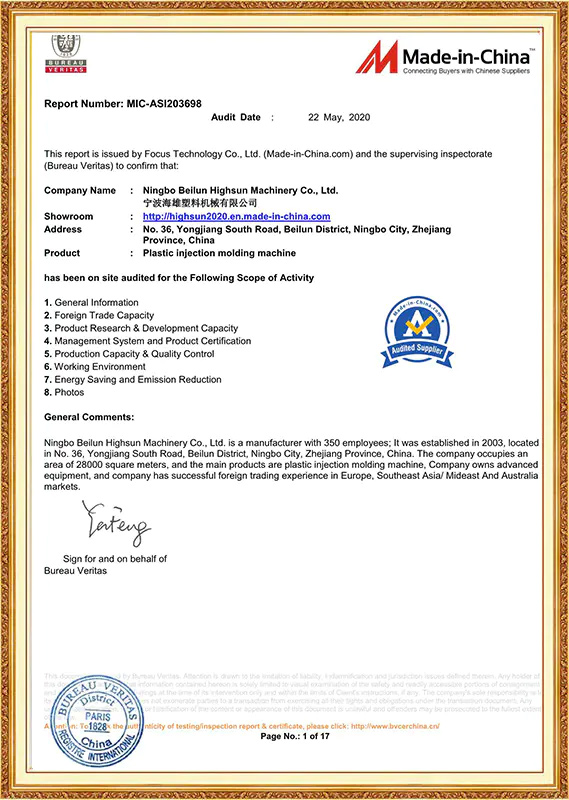

haixiong@highsun-machinery.com No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China

No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China