How PVC Injection Molding Machines Enhance Production Efficiency PVC injection molding machines can significantly enhance production efficiency by streamlining manufacturing processes, improving prod...

READ MORE

|

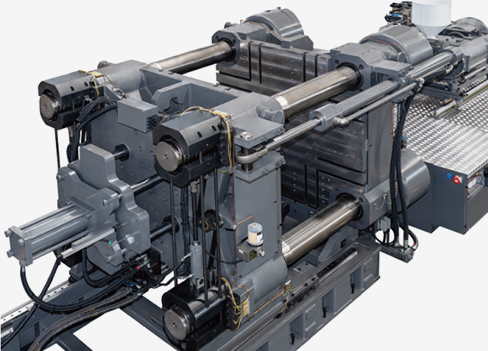

● High-speed hydraulic cylinder matching proportional valve switch module, achieving perfect integration of fast and smooth operation. ● Anti-impact synchronous brake mechanism with mechanical synchronization function. Braking mechanism with buffering function. |

|

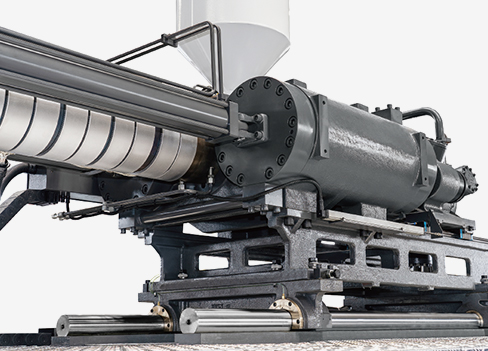

● The latest screw design technology meets the needs of different applications and materials, with a wide range of applications and strong adaptability. ● Convenient assembly structure for plasticizing units, facilitating the exchange of large plasticizing units. |

|

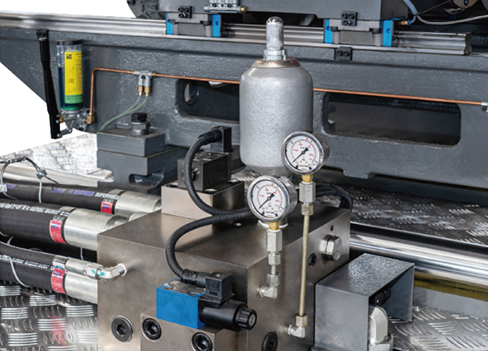

● The newly designed servo-driven hydraulic control system has faster response, lower energy consumption, higher efficiency, and more stable operation. |

|

● Adopting an independent precision filtration system to ensure the cleanliness of hydraulic oil and prolong the service life of the sealing, components. |

|

● Accurate control, reliable and stable, humanized design. ● The HXZ series two plate injection molding machine is equipped with a dedicated control system for two plate machines, which has strong functions, a reliable, stable, and safe system operation. At the same time, it has rich expansion functions and a more user-friendly design. Provide customers with a better user experience. |

How PVC Injection Molding Machines Enhance Production Efficiency PVC injection molding machines can significantly enhance production efficiency by streamlining manufacturing processes, improving prod...

READ MOREThe direct answer is yes: the HXM Servo Injection Molding Machine is designed to deliver high precision, lower energy consumption, and stable production performance, making it ideal for manufacturers ...

READ MOREThe HXYD hybrid injection molding machine represents a significant evolution in manufacturing technology. Combining the strengths of electric and hydraulic systems, it provides an efficient and flexib...

READ MOREA Two Color Injection Molding Machine is an advanced manufacturing system designed to produce plastic parts using two different materials or two different colors in a single molding cycle. This techno...

READ MOREWith the continuous development of industry, intelligent manufacturing and energy conservation and environmental protection have become important trends in the manufacturing industry. Especially in th...

READ MORE1. What is the HXZ High-Performance Two-Platen Injection Molding Machine?

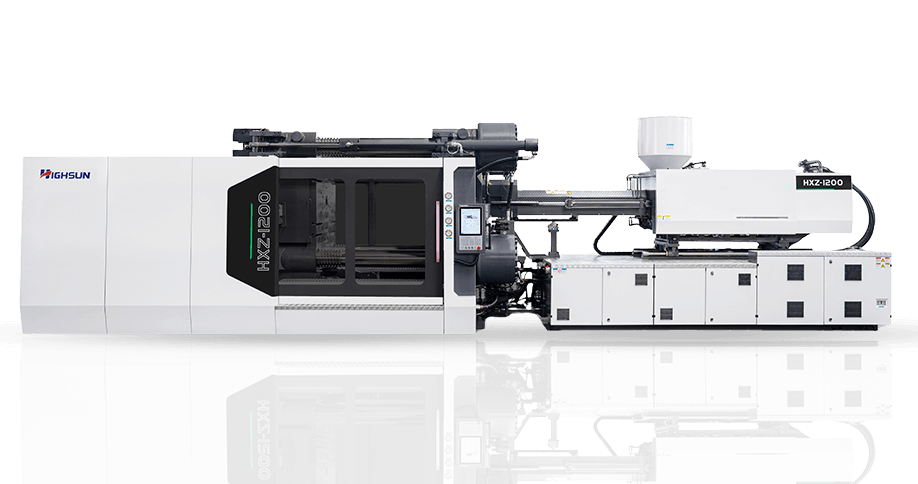

The HXZ high-performance two-platen injection molding machine is a new generation of injection molding equipment that adopts a two-platen clamping structure, combined with a high-speed injection system and intelligent servo control technology. Its main feature is the use of a two-platen mechanism to replace the traditional three-platen structure, resulting in more uniform clamping force transmission, a more compact structure, lower energy consumption, and higher stability. The HXZ series is widely used in automotive interior and exterior parts, large home appliance panels, logistics pallets, household goods, and large engineering plastic products, and is one of the mainstream models for modern high-load, large-scale injection molding needs.

Ningbo Beilun Highsun Machinery Co., Ltd. is a professional China HXZ The Powerful Two-platen Injection Molding Machine Manufacturers and HXZ The Powerful Two-platen Injection Molding Machine Factory, We specialise in producing and marketing high-grade precision plastic injection molding machines under the "HIGHSUN" brand.

2. Applicable Industries and Typical Applications

With its robust structure and high stability, the HXZ high-performance two-platen injection molding machine has become an important choice for the large-scale injection molding industry. Applicable fields include:

Automotive industry: bumpers, instrument panel frames, door interior panels, grilles, etc.

Home appliance industry: TV frames, refrigerator drawers, washing machine drum components, etc.

Logistics and transportation: storage pallets, turnover boxes, large-sized transport containers

Household goods: chairs, tables, large storage bins, flower pots

Industrial parts: large electronic housings, equipment protective covers, engineering plastic components

Its high-load structure and large clamping force make it suitable for molding large plastic products with large volume, uneven wall thickness, or requiring high-pressure injection molding.

3. How to Maintain the HXZ High-Performance Two-Platen Injection Molding Machine

The HXZ high-performance two-platen injection molding machine adopts a two-platen structure, a high-rigidity clamping system, and intelligent servo power, providing high efficiency and high stability for large plastic part production. To ensure that the equipment maintains optimal performance, extends its service life, and reduces downtime, scientific and effective daily maintenance is crucial. The following are key maintenance points for the HXZ high-performance two-platen injection molding machine.

| Maintenance Area | Procedure | Frequency | Technical Specifications |

| Daily Checks | |||

| Platen Parallelism | Measure parallelism with laser alignment tool | Each shift | Tolerance: ≤0.02mm/m² |

| Tie Bar Elongation | Monitor stretch using strain gauges | Daily | Max differential: 0.05% of total length |

| Weekly Maintenance | |||

| Moving Platen Guides | Lubricate linear rails with EP2 grease | Weekly | Grease volume: 3-5cm³ per lubrication point |

| Clamp Cylinder | Check for oil leaks at telescopic cylinders | Weekly | Pressure test at 1.5x operating pressure |

| Monthly Tasks | |||

| Mold Height Adjustment | Verify automatic adjustment system accuracy | Monthly | Positioning repeatability: ±0.01mm |

| Ejection System | Inspect servo ejection rods for straightness | Monthly | Runout tolerance: <0.03mm |

| Quarterly Procedures | |||

| Hydraulic System | Flush and replace oil (ISO VG 46 recommended) | Every 500 hours | Particle count: ≤NAS Class 7 |

| Toggle Mechanism | Inspect wear pads and lubrication distribution | Quarterly | Wear limit: 0.5mm on friction pads |

| Annual Maintenance | |||

| Structural Integrity | Check frame for stress cracks using NDT methods | Annually | Ultrasonic thickness measurement variation: ≤5% of original |

| Servo Drive System | Recalibrate motors and encoders | Annually | Backlash compensation: ≤0.005mm |

4. HXZ High-Performance Two-Platen Injection Molding Machine FAQ

Q1: What are the advantages of the two-platen structure compared to the traditional three-platen type?

A1: Uniform force distribution, stronger rigidity, no mold parallelism problems, smaller footprint, and simpler maintenance, suitable for large and high-precision molds.

Q2: What types of plastic products are suitable? A2: Primarily suitable for large, high-pressure, and high-precision products, such as automotive parts, home appliance panels, and pallets.

Q3: How effective is the energy saving?

A3: The servo system can save 30%–70% of energy, depending on the process cycle and product structure.

Q4: Is it easy to integrate with automated equipment?

A4: Yes, it can be easily integrated with robotic arms, stackers, automatic conveying systems, MES systems, etc., making it suitable for smart factories.

Q5: Is maintenance complicated?

A5: The double-platen structure has fewer moving parts, making maintenance simpler than traditional models, and it also features intelligent maintenance reminders.