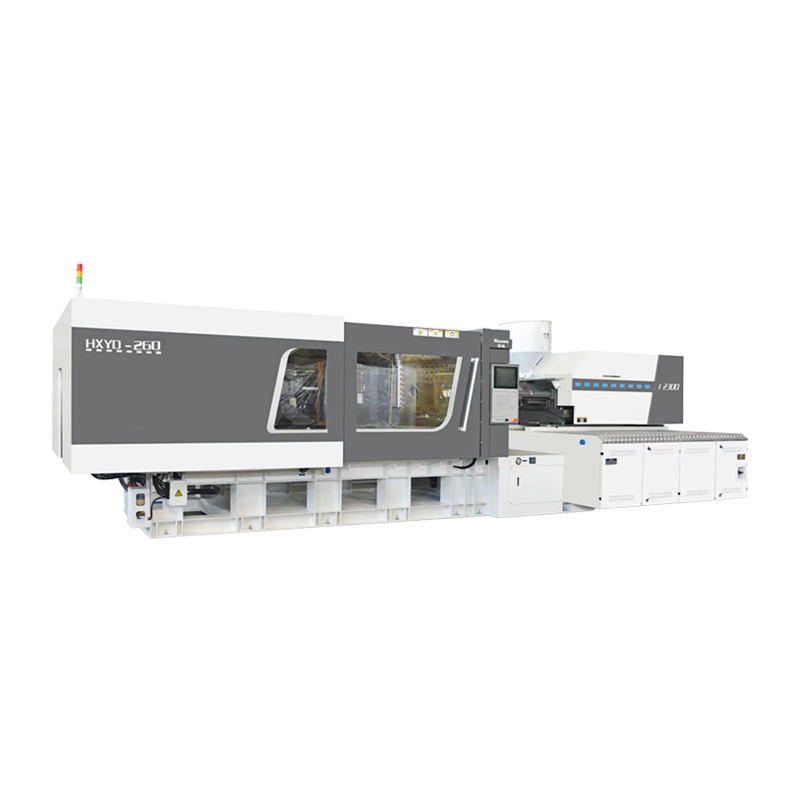

HXYD-260: HXYD hybrid injection molding machine

The HXYD260T injection molding machine combines the hydraulic system's high clamping force with the full-electric drive's high-precision control, making it widely applicable in precision manufacturing fields such as consumer electronics, automotive parts, and medical packaging. Its design integrates energy efficiency, high productivity, and intelligent features, particularly suited for mass production of small to medium-sized, high-precision components.

ENG

ENG  English

English русский

русский Español

Español Português

Português عربى

عربى

+86-188 6861 6288

+86-188 6861 6288 haixiong@highsun-machinery.com

haixiong@highsun-machinery.com No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China

No.36 Yongjiang South Road, Beilun District. Ningbo City, 315800, China