Troubleshooting Common Issues in PET Preform Injection Molding Machines PET preform injection molding machines are vital for producing high-quality plastic bottles and containers. However, like all m...

READ MORE

|

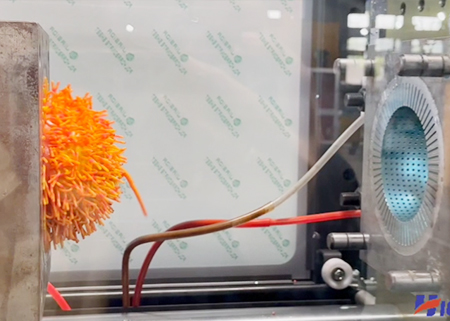

● With major and minor two injection components, can inject synchronously or alternately through the profes-sional computer controlling two screw bars. So as to get the plastic products with beautiful color, we can also manufacture the sandwich plastic products, and the cost is reduced. |

|

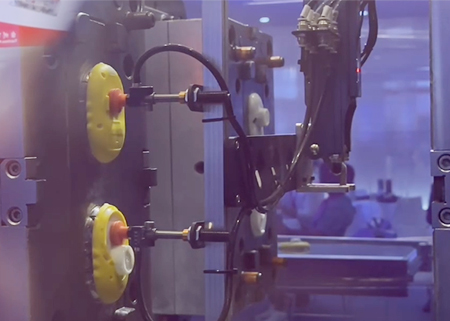

● Leveraging patented rotary technology and intelligent closed-loop control, it achieves ultra-precision positioning of ±0.01°, eliminating mold seam misalignment and material joint lines. The monobloc reinforced structure ensures long-term stability, boosting indexing speed by 40% while extending wear life beyond 5 million cycles. |

|

● Demonstrates superior adaptability to common plastics, including PP, PE, PS, and more, enabling immediate two-shot molding without extensive retooling. Seamlessly meets material requirements across 3C electronics, household goods, toys, and diverse industries, expanding production possibilities. |

Troubleshooting Common Issues in PET Preform Injection Molding Machines PET preform injection molding machines are vital for producing high-quality plastic bottles and containers. However, like all m...

READ MOREHow PVC Injection Molding Machines Enhance Production Efficiency PVC injection molding machines can significantly enhance production efficiency by streamlining manufacturing processes, improving prod...

READ MOREThe direct answer is yes: the HXM Servo Injection Molding Machine is designed to deliver high precision, lower energy consumption, and stable production performance, making it ideal for manufacturers ...

READ MOREThe HXYD hybrid injection molding machine represents a significant evolution in manufacturing technology. Combining the strengths of electric and hydraulic systems, it provides an efficient and flexib...

READ MOREA Two Color Injection Molding Machine is an advanced manufacturing system designed to produce plastic parts using two different materials or two different colors in a single molding cycle. This techno...

READ MORE1. What is a two-color injection molding machine?

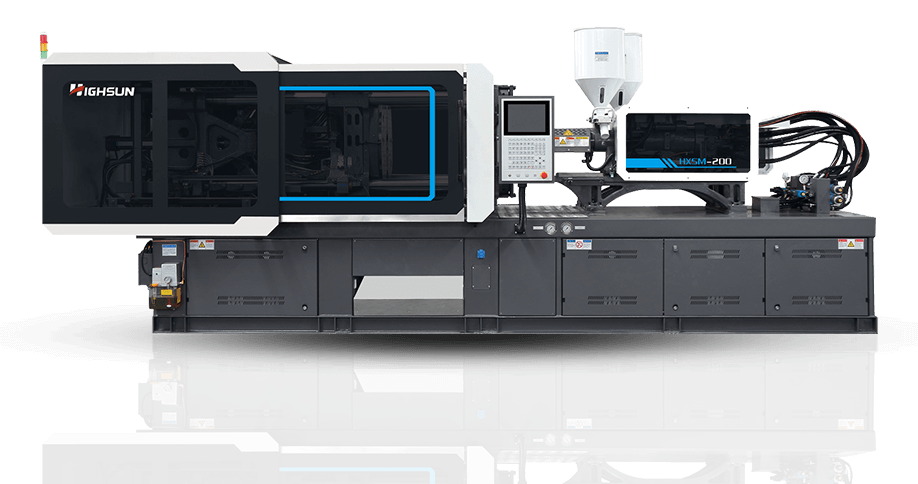

A two-color injection molding machine is an injection molding equipment capable of completing the one-time molding of two different materials or two different colors of plastic on the same machine. It is equipped with a dual injection unit, dual barrels, and a special rotating structure, allowing for two-color, soft-hard combination, or multi-functional integrated injection molding within a single production cycle. By avoiding secondary processing or assembly, this equipment can effectively improve product appearance quality, structural consistency, and production efficiency, making it an important manufacturing equipment for high-end injection molded products.

2. Advantages and Features of Two-Color Injection Molding Machines

The biggest advantage of a two-color injection molding machine is its ability to achieve "one-time molding, multi-color or multi-material fusion." It can significantly improve product appearance, such as two-color buttons and transparent + opaque combination parts; it can also achieve soft-hard combination structures, such as TPU overmolding ABS, improving product feel, anti-slip properties, and structural strength. Compared with traditional secondary processing methods, two-color injection molding reduces manual assembly, lowers scrap rates, and improves dimensional consistency and production efficiency. Its high degree of automation meets the dual demands of high efficiency and high quality in modern factories.

3. Key Maintenance Points for Two-Color Injection Molding Machines

The operation of a two-color injection molding machine requires attention to the synchronous stability of the two injection systems. Operators should reasonably set the temperature, injection speed, and pressure parameters for each section according to the material characteristics to ensure optimal bonding or fusion of the two materials. For maintenance, regularly check the positioning accuracy and lubrication of the rotating mold plate to ensure smooth rotation; check the screw wear, barrel temperature control, and hydraulic or servo system status of the two injection units; and keep the mold guiding parts clean to avoid deviations affecting product accuracy.

| Maintenance Area | Key Tasks | Frequency | Critical Notes |

| Daily Checks | |||

| Dual Injection Units | Check synchronization and material contamination prevention | Every shift | Ensure proper material separation and purge procedures |

| Rotary Plate/Turntable | Inspect rotation mechanism and locking system | Daily | Verify smooth operation and proper alignment |

| Mold Change System | Check alignment and clamping force for both molds | After mold change | Prevent flash and premature wear |

| Weekly Maintenance | |||

| Material Feed System | Clean hoppers, dryers, and check for cross-contamination | Weekly | Critical for color/material purity |

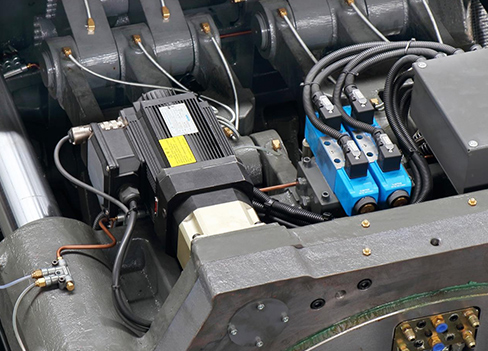

| Hydraulic System | Monitor oil levels and check for leaks in dual circuits | Weekly | Maintain separate systems if machines have independent hydraulics |

| Cooling System | Check both mold temperature control units for consistency | Weekly | Temperature variation affects bonding quality |

| Monthly Tasks | |||

| Screw & Barrel (Both) | Inspect wear and check for material degradation | Monthly | Pay attention to transition areas between materials |

| Electrical Controls | Verify synchronization of control systems | Monthly | Ensure both injection units work in perfect coordination |

| Safety Interlocks | Test rotary plate safety mechanisms | Monthly | Critical for operator protection during rotation |

| Quarterly Procedures | |||

| Rotary Bearing | Inspect and lubricate turntable bearings | Every 3 months | Use high-temperature bearing grease |

| Hydraulic Oil Analysis | Sample and test oil from both systems | Quarterly | Compare results between systems |

| Servo Motors | Check both injection and rotation drive systems | Quarterly | Monitor for unusual vibrations or heat buildup |

4. FAQ: Common Questions about Two-Color Injection Molding Machines

Q1: What is the difference between a two-color injection molding machine and a regular injection molding machine?

A1: A two-color machine has a dual injection unit and a rotating mold structure, allowing for one-time molding of two colors or materials, while a regular machine can only perform single-color, single-material injection molding.

Q2: What materials are suitable for two-color injection molding machines?

A2: It can be used for a wide range of materials, such as ABS, PC, PP, PMMA, TPU, TPE, etc., but attention should be paid to the bonding properties and temperature requirements of different materials. Q3: Is it mandatory to use a rotary mold plate?

A3: Most two-color injection molding machines use a rotary mold plate, but some specific structures can utilize slider switching or in-mold diversion methods.

Q4: Are two-color injection molded products prone to delamination?

A4: As long as the material adhesion is reasonable and the injection temperature and pressure are properly controlled, the product will not delaminate and will have a strong structure.

Q5: Is automation supported?

A5: Yes, it is fully supported and can be integrated with robots, in-mold labeling, and automatic packaging lines to achieve fully automated production.