Choose Based on Product Requirements First — Not Machine Price The right PVC injection molding machine is the one that matches your product size, PVC formulation, and production volume. Clamping force...

READ MORE

|

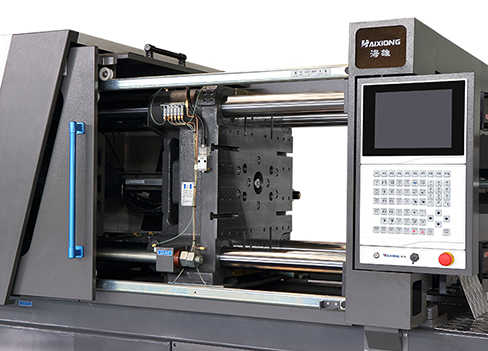

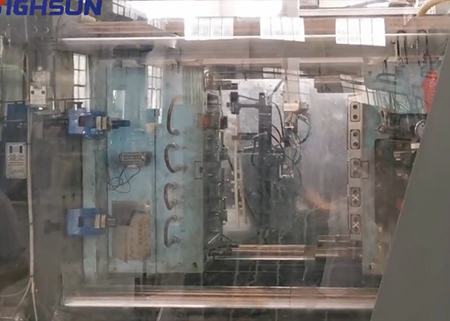

● The ultra-high rigidity square plate and tie-bar structure design caters to international mold design standards.

● Bigger opening stroke, more suitable for deep cavity product molding.

● High-strength box platen is stronger.

|

|

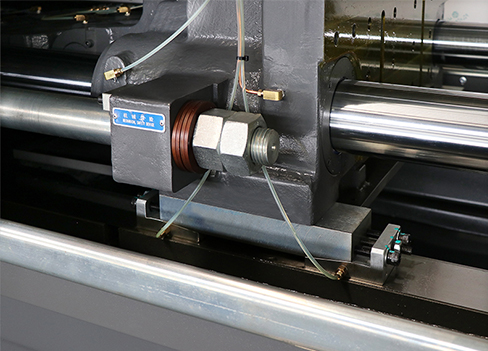

● Newly designed lateral mechanical safety structure; The feet slip structure of the moving mold plate is newly designed with an oblique wedge. |

|

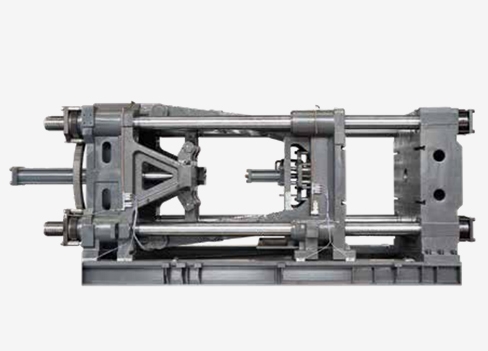

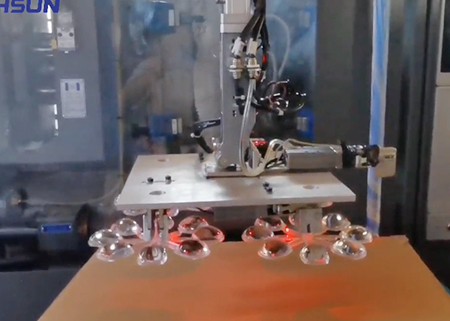

● Optimized toggle structure improves the life of the machine and reduces the maintenance cost. The ejection part is equipped with a forced retracting device as standard; the ejection stroke is longer, and the ejection position can be adjusted freely. ● Side-mounted new mechanical safety structure, more convenient to operate and safer to use. |

|

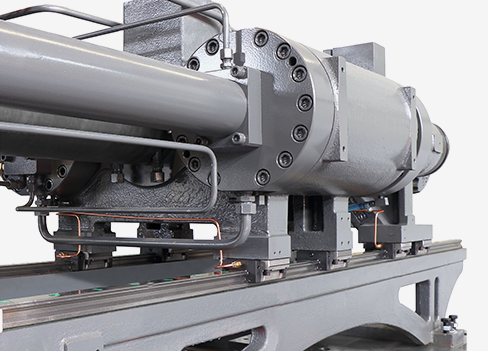

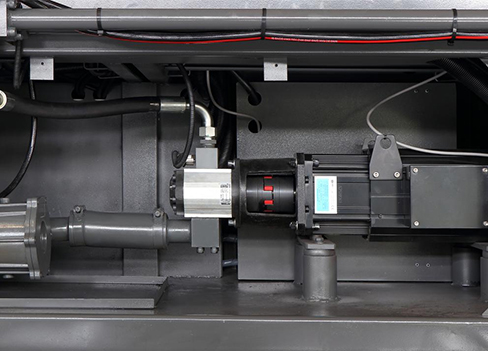

● The plasticizing parts with optimized design can improve the plasticizing ability and injection precision of the machine significantly. Screw transmission adopts the spline to connect and the force is uniform when the screw rotates. ● The moving part is guided by a linear guide rail to reduce friction. |

|

● The hydraulic power system uses motors with high response, high power density, low inertia and noise-reduced to bring a unique feeling of high performance and noise-reduced to customers with an improved screw pump. |

Choose Based on Product Requirements First — Not Machine Price The right PVC injection molding machine is the one that matches your product size, PVC formulation, and production volume. Clamping force...

READ MORETroubleshooting Common Issues in PET Preform Injection Molding Machines PET preform injection molding machines are vital for producing high-quality plastic bottles and containers. However, like all m...

READ MOREHow PVC Injection Molding Machines Enhance Production Efficiency PVC injection molding machines can significantly enhance production efficiency by streamlining manufacturing processes, improving prod...

READ MOREThe direct answer is yes: the HXM Servo Injection Molding Machine is designed to deliver high precision, lower energy consumption, and stable production performance, making it ideal for manufacturers ...

READ MOREThe HXYD hybrid injection molding machine represents a significant evolution in manufacturing technology. Combining the strengths of electric and hydraulic systems, it provides an efficient and flexib...

READ MORE1. What is a Smart Power High-Performance Injection Molding Machine?

A smart power high-performance injection molding machine is a new type of injection molding equipment that integrates advanced servo drive systems, intelligent control technology, and high-precision molding structures. Through real-time data acquisition, closed-loop control, and energy optimization algorithms, it achieves faster molding cycles, more stable product quality, and higher energy efficiency. Compared with traditional hydraulic injection molding machines, smart power machines offer advantages such as high responsiveness, high precision, low energy consumption, and low noise, making them a core piece of equipment for improving productivity and quality in modern manufacturing. This equipment is widely used in industries requiring precision molding, such as automotive parts, 3C electronics, high-end home appliances, medical consumables, and thin-walled packaging.

Ningbo Beilun Highsun Machinery Co., Ltd. is a professional China SP Smart Power High Performance Injection Molding Machine Manufacturers and SP Smart Power High Performance Injection Molding Machine Factory, We specialise in producing and marketing high-grade precision plastic injection molding machines under the "HIGHSUN" brand.

2. Advantages and Features of Smart Power High-Performance Injection Molding Machines

Smart power high-performance injection molding machines have significant advantages in structure, power, and control. First, their power system uses a servo-hydraulic or all-electric drive solution, which can automatically adjust the output according to process requirements, reducing unnecessary energy waste and resulting in significant energy savings. Secondly, the entire machine is equipped with a high-rigidity platen, precision guide rails, and high-speed injection components, ensuring stable mold opening and closing, high injection accuracy, and low repeatability errors. This meets the injection molding needs of high-demand products such as precision structural parts and thin-walled parts. In addition, the intelligent control system supports full-process monitoring, automatic parameter adjustment, mold protection, real-time energy consumption analysis, and remote maintenance, making the production process more transparent, safe, and efficient. Its fast production cycle and stable process performance allow companies to achieve higher productivity and lower manufacturing costs while maintaining quality.

3. Common Problems with Smart Power High-Performance Injection Molding Machines

Common problems encountered when using smart power injection molding machines mainly involve equipment parameter settings, maintenance management, and process matching. For example, if the injection parameters are not set correctly, it may cause problems such as short shots, burrs, and flow marks, requiring precise adjustments based on the product structure and material characteristics. Some companies may be unfamiliar with the automatic parameter adjustment logic of the intelligent system when initially using it, but with accumulated operating experience, the system's intelligent functions can significantly reduce manual debugging time. In addition, the equipment requires regular maintenance of the servo system, oil circuit system, cooling system, and platen mechanism to ensure long-term stability and accuracy. Some companies also focus on energy consumption performance, production cycle time, and mold adaptability, which can usually be effectively improved by optimizing process settings or upgrading the molding solution.

Common Issues Table for Smart Power High-Performance Injection Molding Machines:

| Problem Category | Specific Issue | Possible Causes | Recommended Solutions | Preventive Measures |

| Precision Control | Inconsistent shot weight | 1. Servo valve wear2. Pressure sensor drift3. Backflow in screw | 1. Calibrate servo system2. Replace pressure transducer3. Check non-return valve | Monthly servo calibrationUse high-resolution sensors |

| Energy Efficiency | Higher than expected kWh/kg | 1. Pump/motor efficiency drop2. Unoptimized recovery cycles3. Hydraulic leaks | 1. Conduct energy audit2. Reprogram recovery timing3. Pressure decay test | Install smart energy monitorOptimize PID parameters |

| Smart Features | AI system false alarms | 1. Dirty vision sensors2. Incorrect learning dataset3. EMI interference | 1. Clean optical components2. Retrain neural network3. Improve shielding | Regular sensor maintenanceUpdate firmware quarterly |

| Speed Performance | Cycle time increase >5% | 1. Hydraulic oil degradation2. Servo response lag3. Mold venting issues | 1. Oil analysis/replacement2. Drive system diagnostics3. Clean venting channels | Viscosity monitoringHigh-speed camera analysis |

| Connectivity | IIoT data transmission failure | 1. Network latency2. Protocol mismatch3. Edge device overload | 1. Check 5G/industrial Ethernet2. Verify OPC UA settings3. Upgrade edge computing | Redundant network setupData compression |

| Material Handling | Intelligent feeding errors | 1. RFID tag misreads2. Moisture sensor fault3. Conveyor jams | 1. Antenna alignment check2. Calibrate hygrometers3. Vibration analysis | Preventive RFID maintenanceSmart material tracking |

4. FAQ for Smart Power High-Performance Injection Molding Machines

Q1: What is the energy-saving effect of the smart power high-performance injection molding machine?

A1: Depending on the product category and process requirements, the energy-saving effect can generally reach 30%-80%, which is far higher than traditional hydraulic injection molding machines.

Q2: What types of injection molded products are suitable for this equipment?

A2: It is especially suitable for thin-walled products, high-gloss appearance parts, precision structural parts, multi-cavity mold products, and injection molded parts requiring high dimensional stability.

Q3: Is the intelligent control system complicated? Can a novice operate it?

A3: The system interface is user-friendly, and it has a built-in process database and automatic parameter adjustment function. Novices can quickly get started, while experienced operators can further improve production efficiency.

Q4: Does the smart power injection molding machine require frequent maintenance?

A4: The equipment itself has self-checking and maintenance reminder functions. Regular maintenance such as servo system inspection, fluid replacement, and cooling system maintenance is sufficient.

Q5: Can the equipment be integrated into a smart factory?

A5: Yes. Most smart power injection molding machines support MES, ERP, remote monitoring, and data interconnection interfaces, allowing for easy integration into automated production lines and digital factory systems.