PVC Fittings (such as pipe fittings, valves, pipe clips, etc.) are high-rigidity, corrosion-resistant, and critically sealed infrastructure components used in construction/municipal applications. Their production is characterized by significant material processing challenges, high sensitivity to efficiency and cost, and prominent environmental pressures.

Material Properties:

• Primarily Rigid PVC (UPVC).

• Poor thermal stability with a narrow processing window (160-190°C).

• High melt viscosity.

• Releases corrosive gases (HCl) upon decomposition.

Product Requirements:

▶ Pressure Resistance and Sealing Performance (≥1.6 MPa hydrostatic pressure test).

▶ Chemical Corrosion Resistance (in acidic/alkaline/saline environments)

▶ Dimensional Stability (assembly interface tolerance: ±0.1 mm)

▶ Low Cost (highly price-sensitive for municipal engineering projects)

● Poor thermal stability and unique flow characteristics of PVC material;

● HCl gas corrodes metal components, shortening equipment lifespan;

● High-precision temperature control is required; localized overheating causes decomposition, while temperature inconsistency compromises product quality.

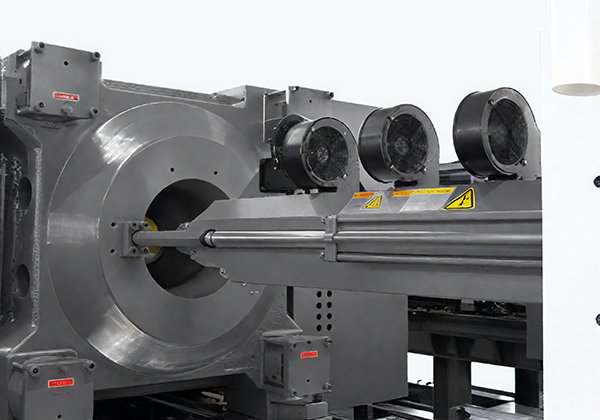

PVC machine

PVC machine Standard with double core pulling device for Fitting molds.

Standard with double core pulling device for Fitting molds. Air fan cooling equipment on the barrel, PID temperature control

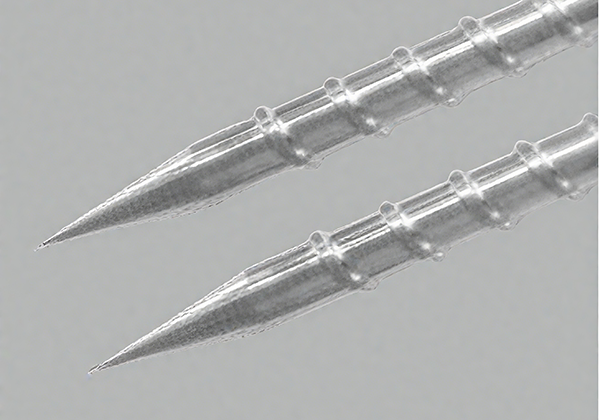

Air fan cooling equipment on the barrel, PID temperature control Special screw and barrel for PVC/CPVC system.

Special screw and barrel for PVC/CPVC system. Widened security doors to compatible with core pulling cylinder structure of

Widened security doors to compatible with core pulling cylinder structure of● Raw Material Selection

● Product Design

● Mold Flow Analysis

● Mold Design Recommendations

● Product Performance

● Product Quality

● User-Friendliness

● Safety Requirements

● Production Line Flow

● Layout, Man, Macie Marcrdng according to Process Flow

● Peripheral Automation

● Smart Connectivity

● Professional Installation and Commissioning

● On-Site Operator Training

● Molding Process Training

● Preventive Maintenance (PM)

● Equipment Upgrade