The application of injection molding machines in the logistics sector is primarily realized through the production of high-strength, standardized, and intelligent logistics carriers and packaging equipment. Specific product categories and their characteristics are as follows:

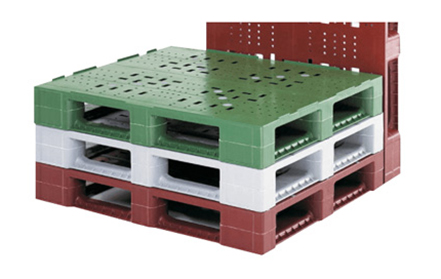

1. Standard Plastic Pallets

Injection molding machines efficiently produce PP/HDPE pallets with 100% recycled material compatibility. Features: Standardized dimensions (max 6000×1500×1000mm), high load-bearing, corrosion-resistant

2. Universal Containers

Materials: PP/HDPE/ABS; Weight ≤50kg; Nestable design saves 60% storage space

3. Stackable Paloxes

APCplus system maintains ±0.5% weight accuracy in recycled product

4. Pallet Containers

Welding-free monolithic structure 3x longer lifespan than wooden containers

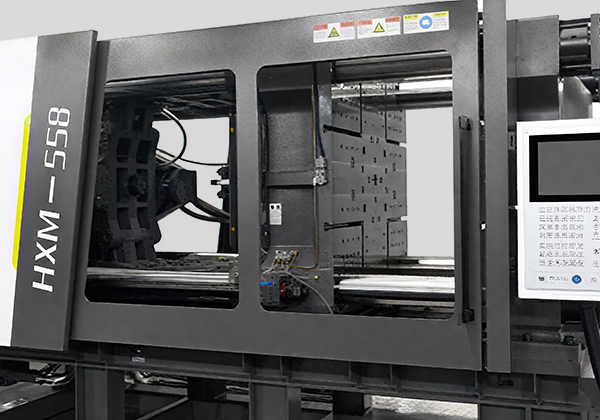

Large-sized pallets are prone to warpage during injection molding,

while insufficient clamping force easily causes flash/burrs at the parting line.

HXM Optimization For Crate / Painting Bucket

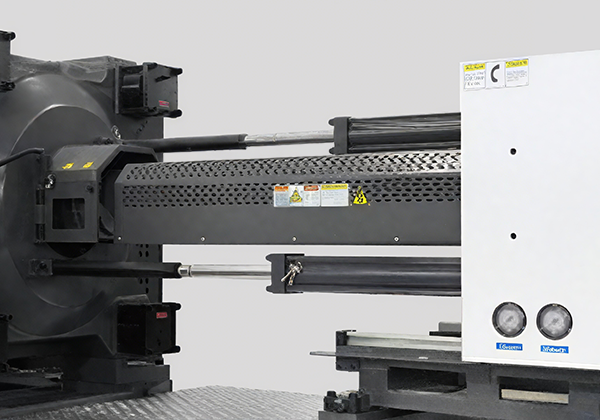

HXM Optimization For Crate / Painting Bucket INJECTION UNIT

INJECTION UNIT CLAMPING UNIT

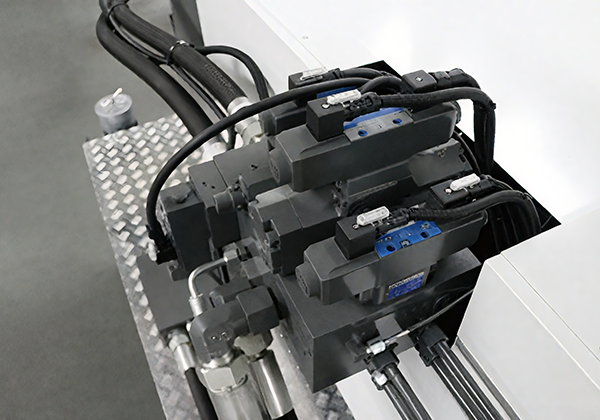

CLAMPING UNIT HYDRAULIC UNIT

HYDRAULIC UNIT POWER SYSTEM

POWER SYSTEM HXZ Two-platen Machine

HXZ Two-platen Machine ● Raw Material Selection

● Product Design

● Mold Flow Analysis

● Mold Design Recommendations

● Product Performance

● Product Quality

● User-Friendliness

● Safety Requirements

● Production Line Flow

● Layout, Man, Macie Marcrdng according to Process Flow

● Peripheral Automation

● Smart Connectivity

● Professional Installation and Commissioning

● On-Site Operator Training

● Molding Process Training

● Preventive Maintenance (PM)

● Equipment Upgrade