Traditional drum-making processes have many drawbacks: slow production, low automation, and inconsistent quality across batches. For example, metal drums require multiple processes such as cutting, welding, and painting, which are cumbersome and highly dependent on manual labor; although blow molding enables one-step molding, it has slow production speed and low yield rate. When paint companies face a surge in orders during peak seasons, traditional processes simply cannot meet the production capacity, often leading to delayed deliveries and disrupting the normal operation of the supply chain.

Injection molding machines, however, are different. They adopt the "mold setting + high-pressure injection" method, enabling fully automated continuous production from raw material melting to finished product demolding. A single machine can produce one drum in just a few tens of seconds. Moreover, the molds are standardized, ensuring excellent dimensional accuracy and uniform wall thickness for each batch of paint drums, which fully meets the large-scale and fast-paced production needs of the paint industry.

AUTO MATIC TOP-IN IML SYSTEM

AUTO MATIC TOP-IN IML SYSTEM HIGH SPEED SIDE-IN IM LSYSTEM

HIGH SPEED SIDE-IN IM LSYSTEM

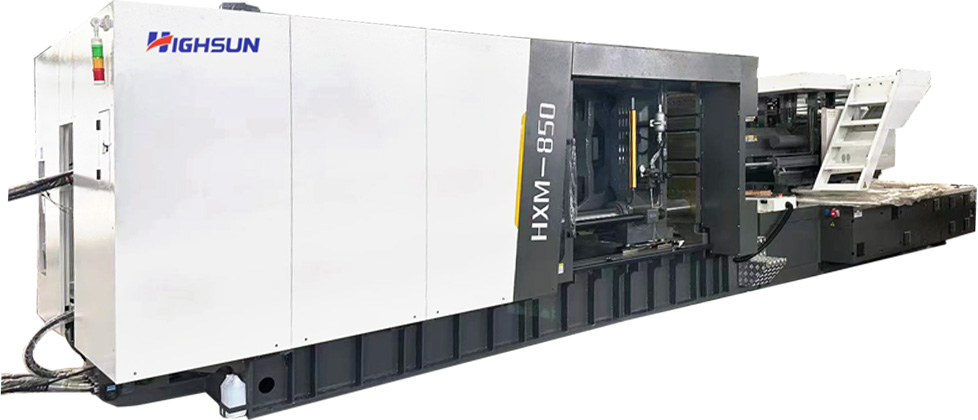

HXM Servo Machine

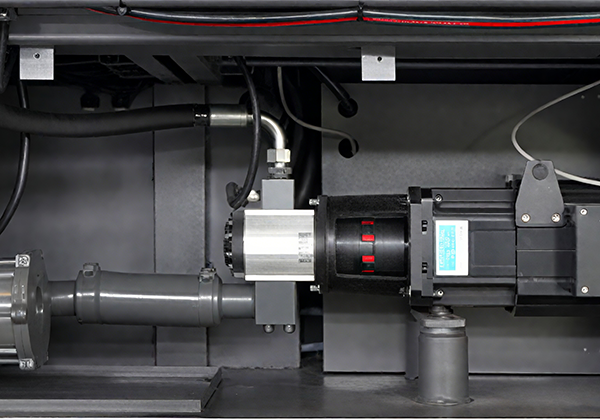

HXM Servo Machine Intelligent Servo Drive

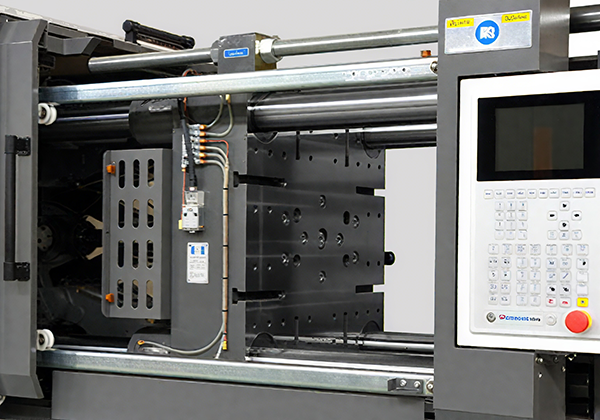

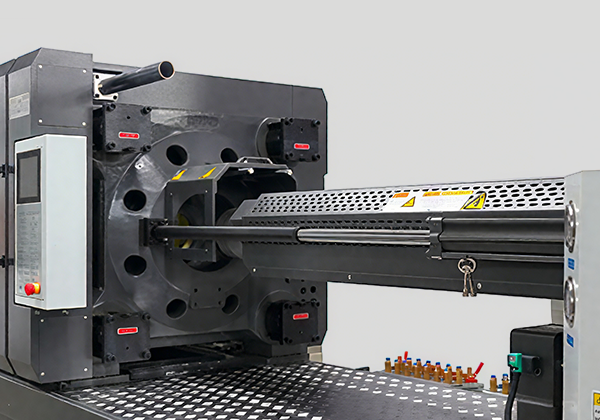

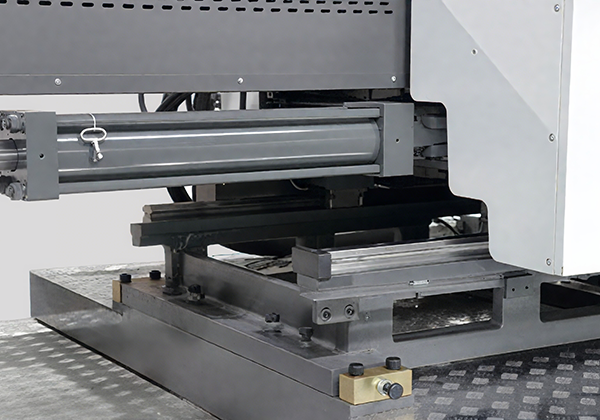

Intelligent Servo Drive T-Type High-Rigidity Platen System

T-Type High-Rigidity Platen System Thermal Management Optimi-

Thermal Management Optimi- High-Rigidity Linear Guide System

High-Rigidity Linear Guide System● Raw Material Selection

● Product Design

● Mold Flow Analysis

● Mold Design Recommendations

● Product Performance

● Product Quality

● User-Friendliness

● Safety Requirements

● Production Line Flow

● Layout, Man, Macie Marcrdng according to Process Flow

● Peripheral Automation

● Smart Connectivity

● Professional Installation and Commissioning

● On-Site Operator Training

● Molding Process Training

● Preventive Maintenance (PM)

● Equipment Upgrade