Injection molding technology, with its high precision, high efficiency, and mass production capabilities, has become a core process in modern medical device manufacturing. Based on current market applications, medical products manufactured by injection molding machines are mainly divided into the following major categories:

Protective Equipment:

Medical mask injection-molded parts (such as nose bridge strips, ear strap buckles), protective face shield frames, goggles components, etc., which played critical roles during the COVID-19 pandemic.

Diagnostic Consumables:

Including pipette tips, reaction cups, PCR testing consumables, PET blood collection tubes, petri dishes, etc.

Therapeutic Devices:

Disposable syringes (barrels, plungers, needle caps), infusion set components, metering valve systems, nebulizer parts, etc.

Medical components demand extremely high dimensional accuracy and stability.

Medical devices must maintain performance stability throughout long-term use.

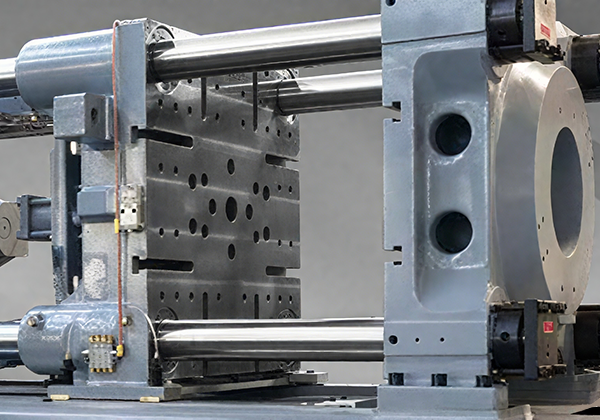

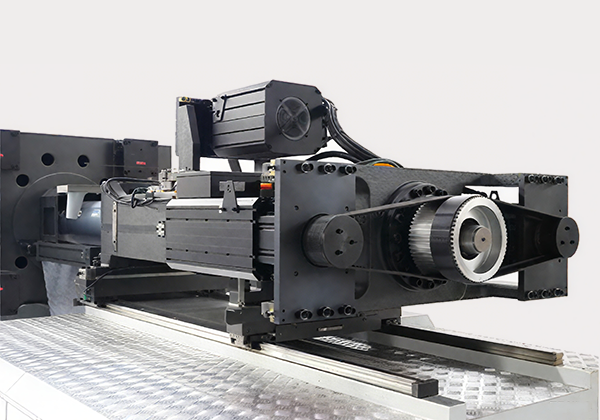

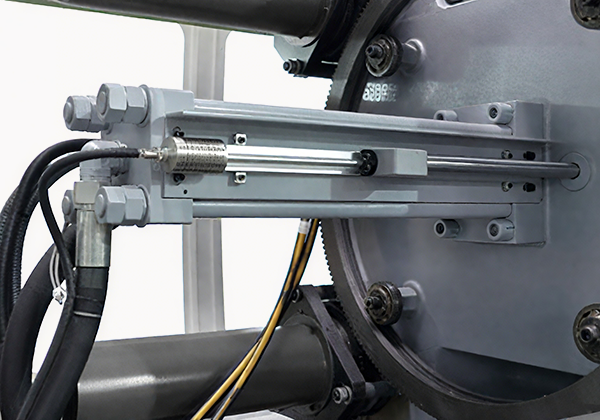

HXYD hybrid injection molding machine

HXYD hybrid injection molding machine Servo motor directly drives the

Servo motor directly drives the All-electric injection unit

All-electric injection unit Adopt digital communication

Adopt digital communication The pedestal adopts linear

The pedestal adopts linear● Raw Material Selection

● Product Design

● Mold Flow Analysis

● Mold Design Recommendations

● Product Performance

● Product Quality

● User-Friendliness

● Safety Requirements

● Production Line Flow

● Layout, Man, Macie Marcrdng according to Process Flow

● Peripheral Automation

● Smart Connectivity

● Professional Installation and Commissioning

● On-Site Operator Training

● Molding Process Training

● Preventive Maintenance (PM)

● Equipment Upgrade