Both major and small appliances are often out in the open in consumers’ homes, so, it is important that the materials used in their design are both durable and visually appealing. Injection molding gives manufacturers a wide range of aesthetic options for appliances such as washers and dryers, dishwashers, ovens, refrigerators, freezers, ranges, and even small appliances like coffee makers and toaster ovens. When products look great in consumers’ homes and exceed their expectations in terms of quality, this helps brands develop favorable reputations.

Injection molding machines handle almost all the manufacturing of plastic parts for small home appliances, primarily used for:

1. Housings/Bodies: This is the largest application category. Examples include the body of an electric kettle, the casing of a coffee maker, the main shell of a vacuum cleaner, the handle of a hairdryer, and the grip of an electric toothbrush.

2.Internal Structural Parts: Such as the bracket inside a rice cooker, the component box in a coffee maker, the air duct in a vacuum cleaner, and the bases and stands for various appliances.

3. See-through Components: The water level window of an electric kettle, the cup of a blender, the water tank of a humidifier, and the cover of an air purifier.

4. Buttons/Control Panels: The keys, knobs, and control panels with patterns or indicator lights on appliances.

5. Lids/Accessories: The lid of a rice cooker, the cap of a kettle, the dustbin and nozzles of a vacuum cleaner, and the nozzle of a hairdryer.

High cosmetic quality requirements for products

Demand for strict dimensional accuracy and stability in products

Challenges posed by material diversity combined with product thin-walling and complex geometries

Production efficiency and cost pressures

HXM Servo Machine

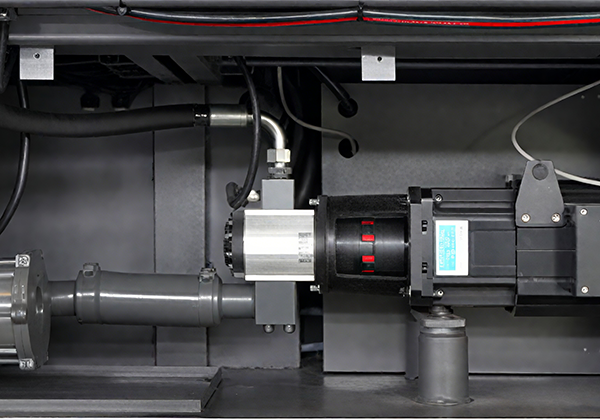

HXM Servo Machine Intelligent Servo Drive System

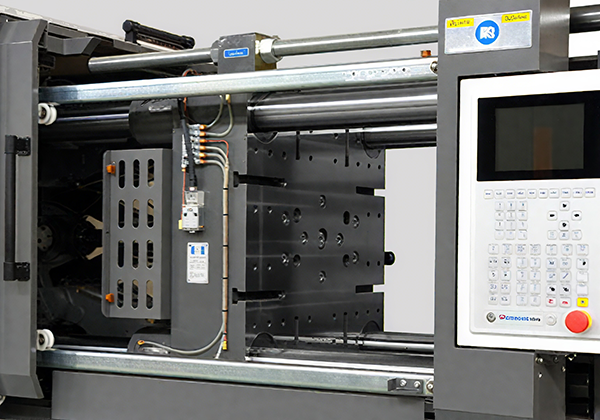

Intelligent Servo Drive System T-Type High-Rigidity Platen System

T-Type High-Rigidity Platen System Thermal Management Opti-

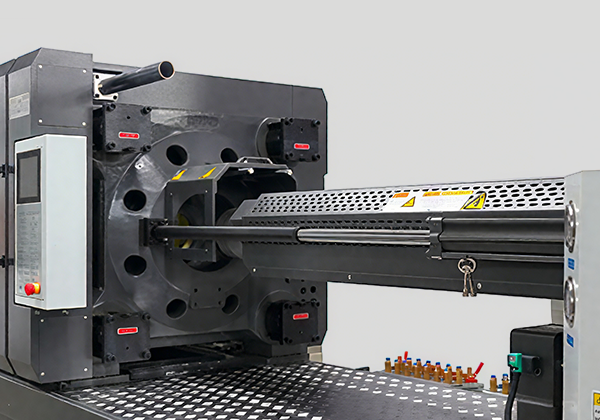

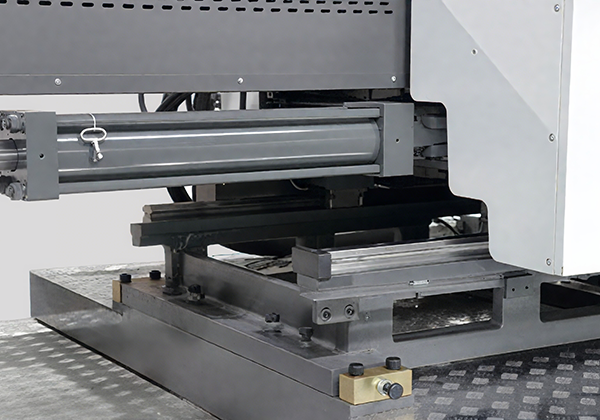

Thermal Management Opti- High-Rigidity Linear Guide System

High-Rigidity Linear Guide System

● Raw Material Selection

● Product Design

● Mold Flow Analysis

● Mold Design Recommendations

● Product Performance

● Product Quality

● User-Friendliness

● Safety Requirements

● Production Line Flow

● Layout, Man, Macie Marcrdng according to Process Flow

● Peripheral Automation

● Smart Connectivity

● Professional Installation and Commissioning

● On-Site Operator Training

● Molding Process Training

● Preventive Maintenance (PM)

● Equipment Upgrade