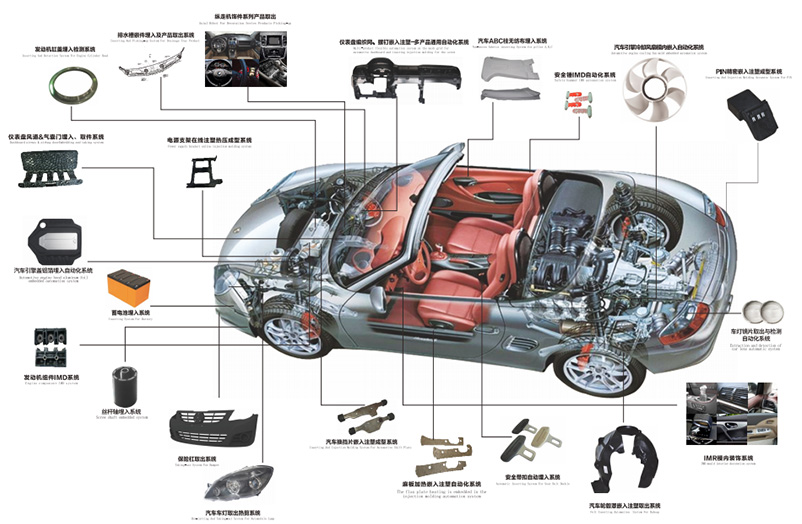

Exterior Parts:

Front/Rear Bumpers

Grilles

Spoilers

Wheel Arches / Fender Flares

Door Handles

Lamp Housings/Lenses

Mirror Housings

Side Skirts

Electrical & Electronic (E/E) Parts:

Sensor Housings/ Sensor Casings

Control Unit Housings/

ECU (Electronic Control Unit) Casings

Relay Boxes

Various Connectors

|

Interior Parts: |

Functional/Structural Parts: |

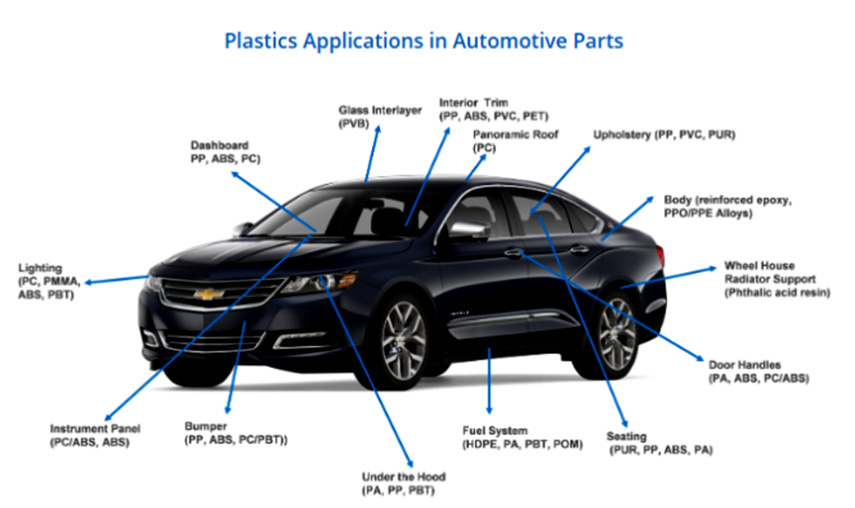

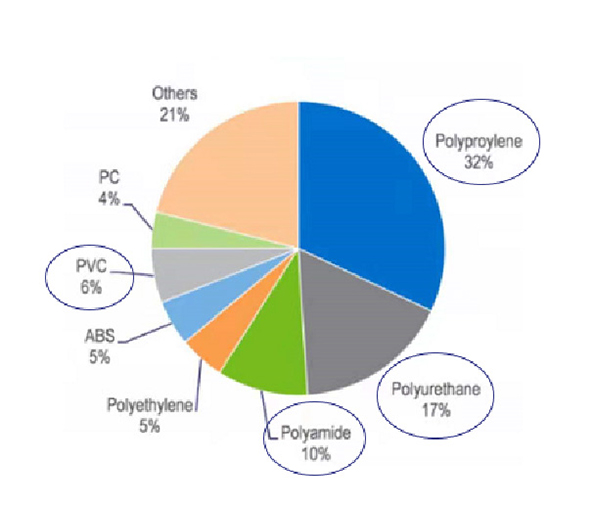

The automotive industry is the third most important consuming sector of polymers after packaging and building & construction. Therefore, changes in the material usage can have major implications on polymer demand and the financial performance of polymer producers.Currently, there are about 30,000 parts in a vehicle, out of which 1/3 are made of plastic. In total, about 39 different types of basic plastics and polymers are used to make an automobile. More than 70% of the plastic used in automobiles comes from four polymers: polypropylene, polyurethane, polyamides and PVC.

→Automotive parts demand exceptionally high dimensional accuracy/tolerance.

→Material diversity complicates process development and elevates material costs.

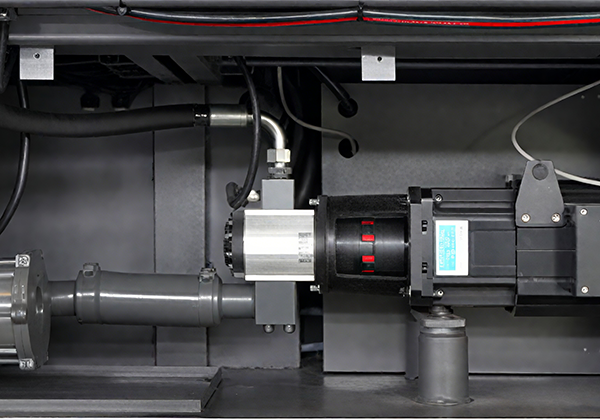

→Injection molding is energy-intensive, with significant energy cost contributions

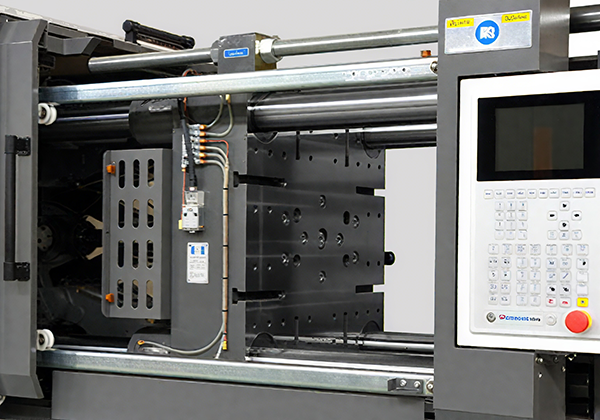

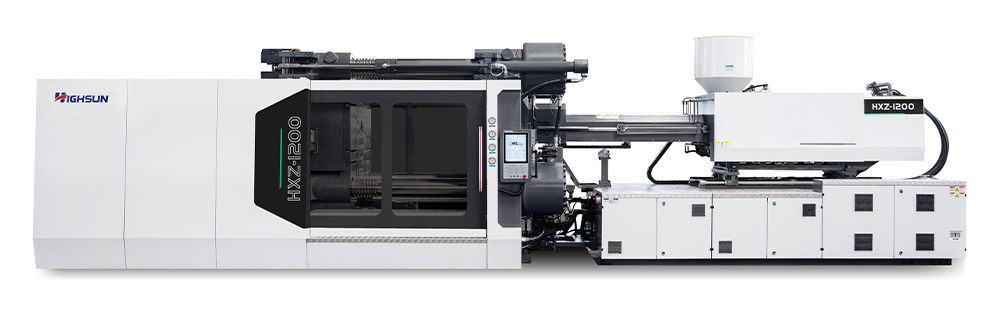

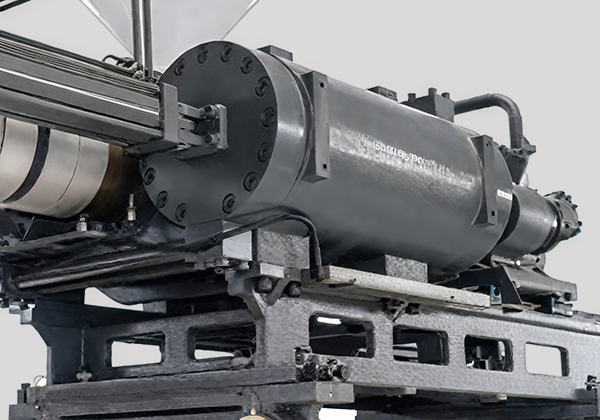

HXM servo machine

HXM servo machine  Intelligent Servo Drive

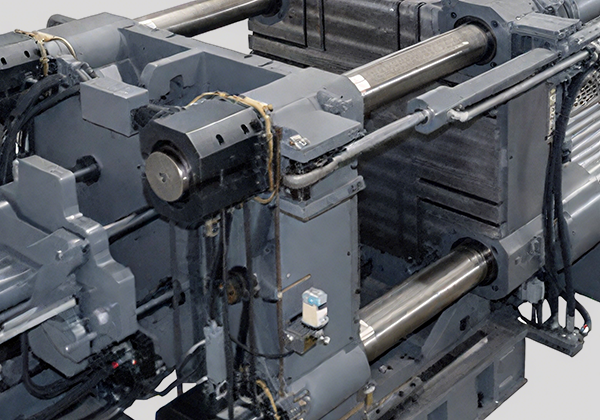

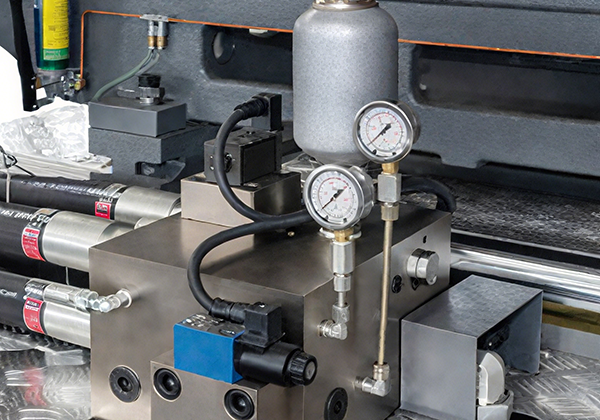

Intelligent Servo Drive T-Type High-Rigidity Platen System

T-Type High-Rigidity Platen System Thermal Management Opti-

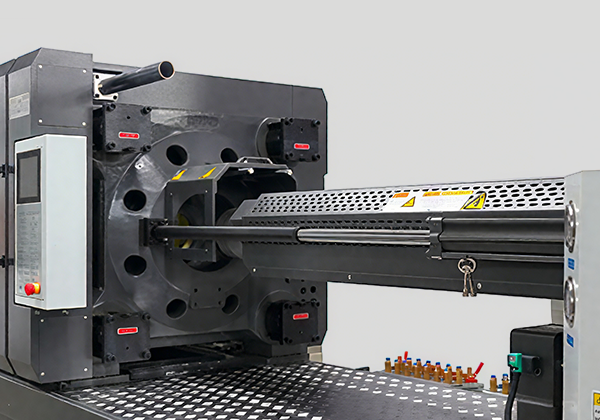

Thermal Management Opti- HXZ Two-platen Machine

HXZ Two-platen Machine Compact Structure,

Compact Structure, Specialized Screw

Specialized Screw Energy-Efficient & High-Perfor-

Energy-Efficient & High-Perfor-● Raw Material Selection

● Product Design

● Mold Flow Analysis

● Mold Design Recommendations

● Product Performance

● Product Quality

● User-Friendliness

● Safety Requirements

● Production Line Flow

● Layout, Man, Macie Marcrdng according to Process Flow

● Peripheral Automation

● Smart Connectivity

● Professional Installation and Commissioning

● On-Site Operator Training

● Molding Process Training

● Preventive Maintenance (PM)

● Equipment Upgrade