Electricity powers almost every aspect of our lives, at home and in our jobs, at work and at play. And everywhere that we find electricity, we also find plastics. In the kitchen, there are the labour-saving devices that we wouldn’t be without; washing machines, microwave ovens, kettles. In the living room is the television, the video or the music system, while at work, we may use a computer. a fax machine or a telephone. Plastics make progress possible, making electrical goods safer, lighter, more attractive, quieter. more environmentally friendly and more durable.

Brown Goods

The stylish appearance of modern VCRs, CD players, DVD systems, Personal Computers and TV sets owes much to the design freedom granted by plastics.

White Goods

Plastics make hygienic and attractive knobs, handles and door facings on cookers; liners, handles and internal fittings on refrigerators and freezers; housings and tops on washing machines and dishwashers.

Small White

Goods Safety is a key requirement for goods such as food processors, toasters, kettles and hairdryers - and plastics make it possible.

Insufficient dimensional accuracy and consistency

High incidence of appearance defects

Material incompatibility issues / Poor material adaptability

High energy consumption and resulting cost pressures

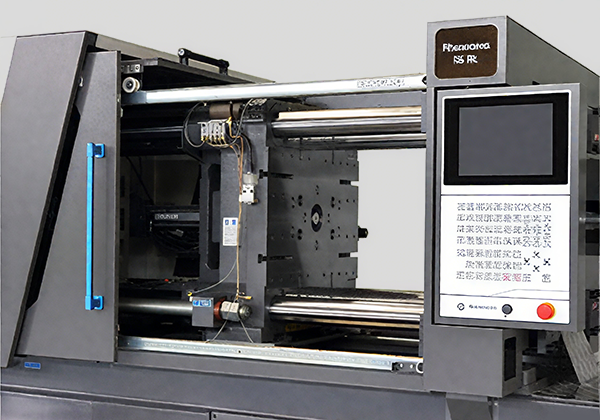

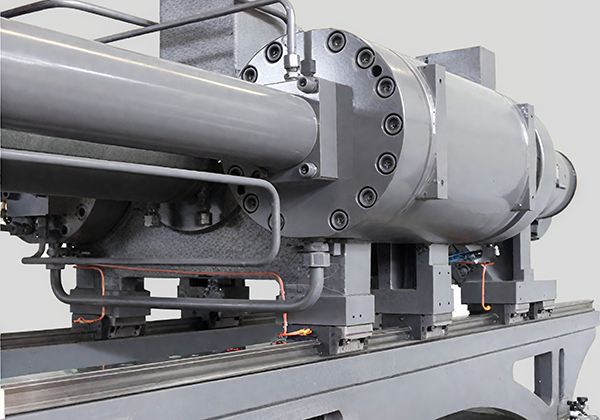

SP Smart Power Machine

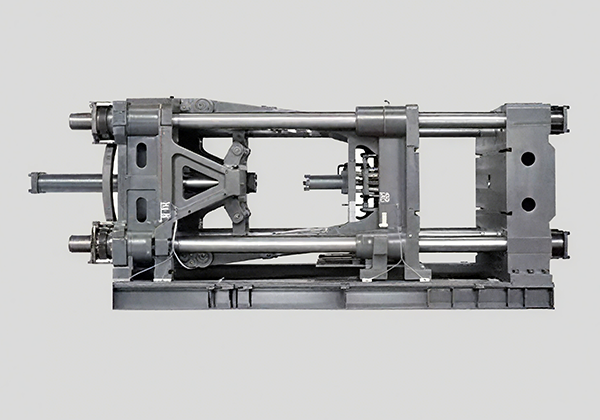

SP Smart Power Machine Bigger opening stroke, more suitable for deep cavity product molding

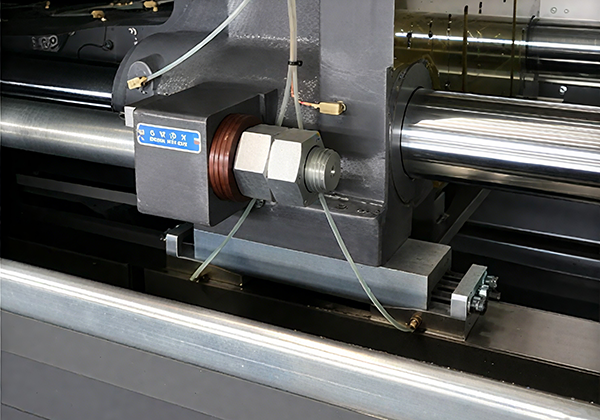

Bigger opening stroke, more suitable for deep cavity product molding  Newly designed lateral mechanical safety structure ; The feet slip structure of moving mold-plate is newly designed with oblique-wedge.

Newly designed lateral mechanical safety structure ; The feet slip structure of moving mold-plate is newly designed with oblique-wedge.  Side-mounted new mechanical safety structure, more convenient to operate and safer to use.

Side-mounted new mechanical safety structure, more convenient to operate and safer to use.  Bigger opening stroke, more suitable for deep cavity product molding

Bigger opening stroke, more suitable for deep cavity product molding ● Raw Material Selection

● Product Design

● Mold Flow Analysis

● Mold Design Recommendations

● Product Performance

● Product Quality

● User-Friendliness

● Safety Requirements

● Production Line Flow

● Layout, Man, Macie Marcrdng according to Process Flow

● Peripheral Automation

● Smart Connectivity

● Professional Installation and Commissioning

● On-Site Operator Training

● Molding Process Training

● Preventive Maintenance (PM)

● Equipment Upgrade