Polyethylene terephthalate (PET) offers superior packaging properties compared to alternatives, making it a preferred choice. Key advantages include high transparency, a glossy surface, excellent stability, strong pressure resistance, effective barrier properties, and light weight. It is widely recognized as the clear plastic of choice for packaging foods and beverages, particularly in convenient-sized soft drinks.

Despite growing environmental concerns, demand for PET bottles and rigid packaging continues to rise, according to a recent Smithers study.

While COVID-19 presents immediate challenges, advances in recycling technologies and the development of alternative feedstocks are projected to become increasingly critical over the next five years (2021-2026). The PET packaging market, valued at USD 55.52 billion in 2020, is expected to reach USD 74.2 billion by 2026, growing at a CAGR of 3.7% to 5% during the forecast period.

● Filling Difficulties: Sharp Increase in Melt Flow Resistance Due to Thin Walls

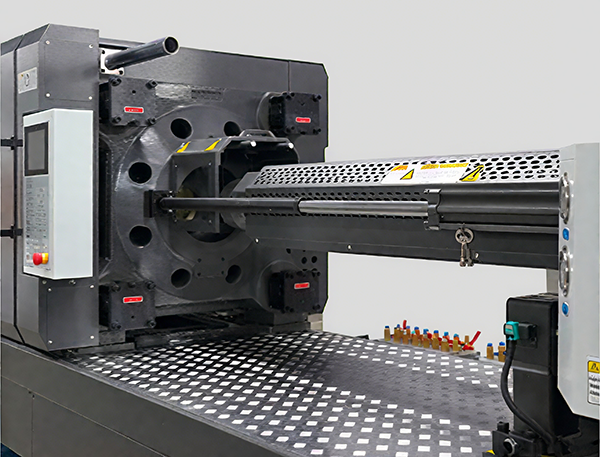

● Flash & Mold Damage: Insufficient Clamping System Pressure Capacity

● Surface Defects: Flow Marks & Burn Marks Induced by High-Speed Filling

● Cooling Warpage: Non-Uniform Shrinkage from Wall Thickness Variations

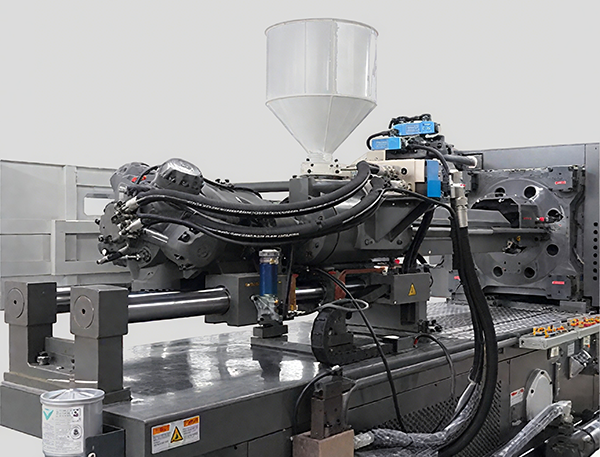

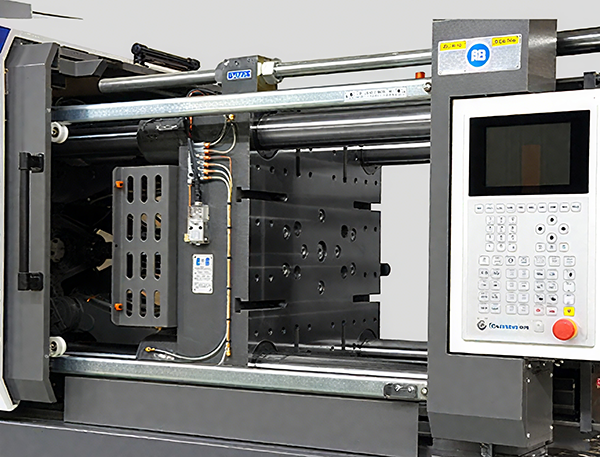

PET Preform Injection Molding Machine

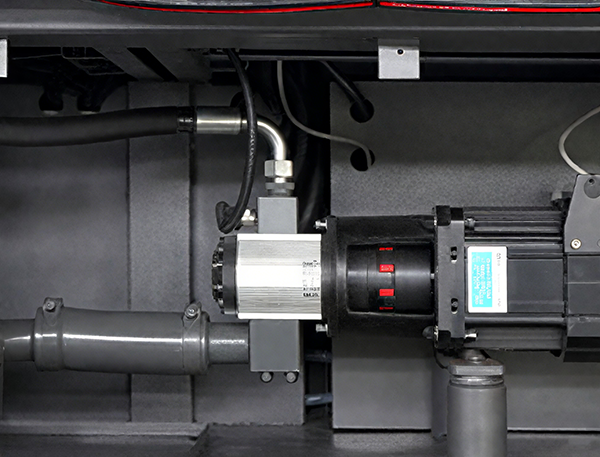

PET Preform Injection Molding Machine High-Torque Plasticization Motor

High-Torque Plasticization Motor Specialized Screw Design

Specialized Screw Design Enhanced Power &

Enhanced Power & Dedicated Cooling Circuit &

Dedicated Cooling Circuit &

● Raw Material Selection

● Product Design

● Mold Flow Analysis

● Mold Design Recommendations

● Product Performance

● Product Quality

● User-Friendliness

● Safety Requirements

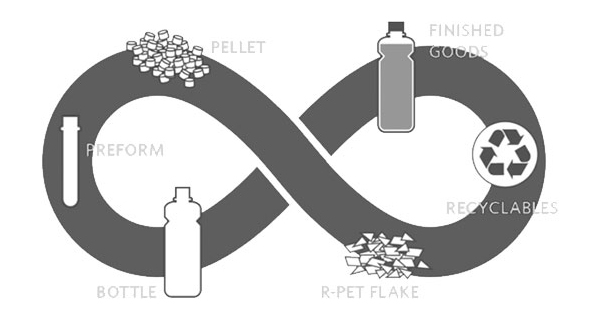

● Production Line Flow

● Layout, Man, Macie Marcrdng according to Process Flow

● Peripheral Automation

● Smart Connectivity

● Professional Installation and Commissioning

● On-Site Operator Training

● Molding Process Training

● Preventive Maintenance (PM)

● Equipment Upgrade